Driven Steel Piles All Sizes High Capacity Foundation Piling U Shape Steel Sheet Pile

Product Detail

| Item Category | Specific Parameter Description |

|---|---|

| Steel Grade | SY390 |

| Executive Standard | Complies with the requirements of JIS G 3101 and adheres to the Japanese Industrial Standard (JIS Standard) system |

| Delivery Cycle | 10 to 20 days |

| Qualification Certifications | Has obtained certifications including ISO9001 Quality Management System, ISO14001 Environmental Management System, ISO18001 Occupational Health and Safety Management System, as well as CE FPC certification and SGS certification |

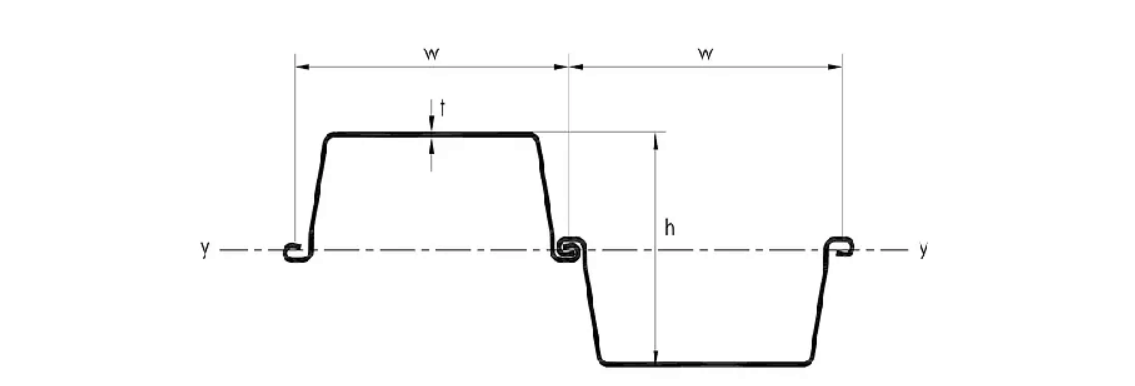

| Width Specifications | Two fixed dimensions are available: 400 mm (equivalent to 15.75 inches) and 600 mm (equivalent to 23.62 inches) |

| Height Range | 100 mm (3.94 inches) to 225 mm (8.86 inches) |

| Thickness Range | 6 mm (0.24 inches) to 25 mm (0.98 inches) |

| Length Specifications | Regular lengths cover 6 meters to 24 meters, among which 9 meters, 12 meters, 15 meters, and 18 meters are standard commonly used sizes; customized special lengths are available |

| Product Type | Includes two categories: U-Type Steel Sheet Piles and Z-Type Steel Sheet Piles |

| Processing Services | Can provide cutting, punching, welding processing, and customized machining services |

| Material Composition | The chemical composition ratio is strictly controlled: Carbon (C) content ≤ 0.20%, Manganese (Mn) content ≤ 1.60%, Phosphorus (P) content ≤ 0.035%, Sulfur (S) content ≤ 0.035% |

| Material Compliance | Fully meets the provisions on chemical composition in the JIS SY390 standard |

| Mechanical Properties | Yield strength ≥ 390 MPa (Megapascals); Tensile strength ranges from 500 MPa to 600 MPa; Elongation ≥ 16% |

| Production Process | Manufactured using the hot-rolled process |

| Optional Dimension Models | Includes specifications such as PU400×100, PU400×125, PU400×150, PU500×200, PU500×225, PU600×130, etc. |

| 0×130, etc. | |

| Interlock Types | Three types are available: Larssen interlock, hot-rolled interlock, and cold-rolled interlock |

| Structural Standard | Complies with the engineering construction standards in the Japanese Industrial Standard (JIS) |

| Application Scenarios | Widely used in port and wharf construction, bridge engineering, deep foundation pit support, cofferdam construction, river and coastline protection, water conservancy projects, flood control facilities, and other fields |

JIS Sy390 U Type Steel Sheet Pile Size

| JIS / Model | SY390 Model | Effective Width (mm) | Effective Width (in) | Effective Height (mm) | Effective Height (in) | Web Thickness (mm) |

|---|---|---|---|---|---|---|

| PU400×100 | SY390 Type 1 | 400 | 15.75 | 100 | 3.94 | 12 |

| PU400×125 | SY390 Type 2 | 400 | 15.75 | 125 | 4.92 | 14 |

| PU400×150 | SY390 Type 3 | 400 | 15.75 | 150 | 5.91 | 16 |

| PU500×200 | SY390 Type 4 | 500 | 19.69 | 200 | 7.87 | 18 |

| PU500×225 | SY390 Type 5 | 500 | 19.69 | 225 | 8.86 | 19 |

| PU600×130 | SY390 Type 6 | 600 | 23.62 | 130 | 5.12 | 13 |

| PU600×210 | SY390 Type 7 | 600 | 23.62 | 210 | 8.27 | 19 |

| PU750×225 | SY390 Type 8 | 750 | 29.53 | 225 | 8.86 | 15 |

| Web Thickness (in) | Unit Weight (kg/m) | Unit Weight (lb/ft) | Material | Yield Strength (MPa) | Tensile Strength (MPa) | Americas Applications | Southeast Asia Applications |

|---|---|---|---|---|---|---|---|

| 0.47 | 52 | 34.8 | SY390 / JIS G3101 | 390 | 500–600 | Flood levees, U.S. Gulf Coast | Irrigation, Philippines & Indonesia |

| 0.55 | 65 | 43.5 | SY390 / JIS G3101 | 390 | 500–600 | Building foundations, Midwest U.S. | Drainage & channels, Bangkok |

| 0.63 | 82 | 54.6 | SY390 / JIS G3101 | 390 | 500–600 | Seepage control, Houston Port & Texas | Land reclamation, Singapore |

| 0.78 | 110 | 73.2 | SY390 / JIS G3101 | 390 | 500–600 | Riverbank & coastal protection, California | Deep-sea port, Jakarta |

| 0.48 | 80 | 53.0 | SY390 / JIS G3101 | 390 | 500–600 | Deep foundation pits, Vancouver Port | Land reclamation, Malaysia |

| 0.60 | 120 | 79.9 | SY390 / JIS G3101 | 390 | 500–600 | Industrial waterfront retaining walls, U.S. | Coastal industrial reinforcement, Ho Chi Minh City |

JIS Sy390 U Type Steel Sheet Pile Corrosion prevention solution

Americas:HDG to ASTM A123 (min zinc coat ≥85 µm); 3PE coating is optional; all finishes are RoHS qaulified.

Southeast Asia: With a thick layer of hot-dip galvanization (above 100μm) and 2 layers of epoxy coal tar coating, it can be tested by 5000 hours salt spray without rust, suitable for application in tropical marine atmosphere.

JIS Sy390 U Type Steel Sheet Pile Locking and waterproof performance

Design: Yin-yang interlock, permeability ≤1×10⁻⁷ cm/s

Americas: Meets ASTM D5887 seepage prevention standard

Southeast Asia: Groundwater-seepage resistant for tropical rainy seasons

JIS Sy390 U Type Steel Sheet Pile Production Process

Steel Selection:

Select structural steel that meets your project’s mechanical and performance needs.

Heating:

Heat billets/slabs to ~1,200°C for malleability.

Hot Rolling:

Roll steel into U channels with rolling mills.

Cooling:

Air or fire cool cool in water for the desired effect.

Straightening & Cutting:

Measure the exact dimensions and cut to standard size or length or to special size or length.

Quality Inspection:

Conduct dimensional, mechanical, and visual tests.

Surface Treatment (Optional):

Apply paints, galvanizing or rust-preventive oils as needful.

Packaging & Shipping:

Bundle, protect, and load for transport.

JIS Sy390 U Type Steel Sheet Pile Main Application

Harbor and Dock Construction: Steel sheet piles form a rigid wall to retain shore protection.

Bridge Engineering: They enhance the load-carrying capacity and act as scour protection for bridge piers when driven as batter piles.

Underground Parking / Deep Foundation Support: Safe, effective lateral support for your excavation.

Water Conservancy Projects: Offer high efficient water barriers for river training, dam strengthening and cofferdam construction.

Our Advantages

Local Support: Our bilingual local offices ensure smooth communication.

Material Ready: All required materials are on hand.

Secure Packaging: Sheet piles are tightly banded with padding and water protection.

Timely Delivery: Piles arrive safely and on schedule.

Packaging & Shipping

Packaging of Steel Sheet Piles

Bundling: Bundles are tightly secured using steel or plastic straps.

End Protection: Ends are safeguarded with plastic caps or wooden blocks.

Rust Protection: Bundles are shielded with waterproof paper, anti-rust oil, or plastic film.

Delivery of Steel Sheet Piles

Loading: Bundles can be lifted onto trucks, flats, or into containers using a forklift or crane.

Stability: Bundles are securely packed to prevent movement during transport.

Unloading: Bundles are handled carefully on-site for safe and easy placement.

FAQ

1. What is SY390 Steel Sheet Pile?

SY390 is a hot-rolled, high-strength steel sheet pile (JIS G3101, grade 390) commonly used in ports, harbours, rivers, and other water protection projects.

2. What types and sizes are available?

Two profiles are available: U-type and Z-type. Widths range from 400–750 mm, heights from 100–225 mm, and thicknesses from 6–25 mm. Custom lengths and dimensions are also available.

3. What surface treatments are available?

The standard finish is untreated. Optional treatments include hot-dip galvanising, epoxy coating, and anti-corrosion coatings for marine, industrial, or harsh environments.

4. What is the delivery time?

Typically 10–20 days, depending on order quantity, destination, and customisation.

5. What certifications does SY390 have?

SY390 complies with ISO 9001, ISO 14001, ISO 18001, CE FPC, and JIS G3101 standards for chemical and mechanical properties.

6. Can SY390 be customised for specific applications?

Yes, it can be cut to length, punched, slotted, welded, and treated with customised surface coatings to meet project requirements.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506