EN 10025 is a European standard for hot-rolled structural steel, which specifies the chemical composition, mechanical properties, and testing methods for carbon steel and low-alloy high-strength steel.

EN 10025 S235 / S275 / S355 Steel I beam/IPE/IPN

| Material Standard | EN 10025 S235 / S275 / S355 Steel IPE/IPN | Yield Strength |

|

| Dimensions | W8×21 to W24×104 (inches) | Length | Stock for 6 m & 12 m, Customized Length |

| Dimensional Tolerance | Conforms to GB/T 11263 or ASTM A6 | Quality Certification | EN 10204 3.1 material certification & SGS/BV third-party testing report (tensile and bending tests) |

| Surface Finish | Hot-dip galvanizing, paint, etc. Customizable | Applications | Building Construction,Bridges,Industrial Structures,Marine and Transportation,Miscellaneous |

| Carbon Equivalent | Ceq≤0.45%(Ensure good weldability) Explicitly labeled "Compatible with AWS D1.1 welding code" |

Surface quality | No visible cracks, scars, or folds. Surface flatness: ≤2mm/m Edge perpendicularity: ≤1° |

| Property | S235 | S275 | S355 | Advantage / Notes |

|---|---|---|---|---|

| Yield Strength | ≥ 235 MPa / 34 ksi | ≥ 275 MPa / 40 ksi | ≥ 355 MPa / 51.5 ksi | Higher grade steel increases load capacity |

| Tensile Strength | 360–510 MPa / 52–74 ksi | 430–580 MPa / 62–84 ksi | 470–630 MPa / 68–91 ksi | S355 has highest tensile strength for heavy-duty structures |

| Elongation | ≥ 26% | ≥ 23% | ≥ 22% | S235 offers better ductility for fabrication |

| Weldability | Excellent | Excellent | Excellent | All grades suitable for structural welding; S355 may require preheating in thick sections |

| Typical Applications | Light structures, low/medium-load beams | Medium-load beams and columns | High-load beams, long-span bridges, industrial buildings | Select steel grade based on load and span requirements |

| Shape | Depth (in) | Flange Width (in) | Web Thickness (in) | Flange Thickness (in) | Weight (lb/ft) |

| W8×21(Sizes Available) | 8.06 | 8.03 | 0.23 | 0.36 | 21 |

| W8×24 | 8.06 | 8.03 | 0.26 | 0.44 | 24 |

| W10×26 | 10.02 | 6.75 | 0.23 | 0.38 | 26 |

| W10×30 | 10.05 | 6.75 | 0.28 | 0.44 | 30 |

| W12×35 | 12 | 8 | 0.26 | 0.44 | 35 |

| W12×40 | 12 | 8 | 0.3 | 0.5 | 40 |

| W14×43 | 14.02 | 10.02 | 0.26 | 0.44 | 43 |

| W14×48 | 14.02 | 10.03 | 0.3 | 0.5 | 48 |

| W16×50 | 16 | 10.03 | 0.28 | 0.5 | 50 |

| W16×57 | 16 | 10.03 | 0.3 | 0.56 | 57 |

| W18×60 | 18 | 11.02 | 0.3 | 0.56 | 60 |

| W18×64 | 18 | 11.03 | 0.32 | 0.62 | 64 |

| W21×68 | 21 | 12 | 0.3 | 0.62 | 68 |

| W21×76 | 21 | 12 | 0.34 | 0.69 | 76 |

| W24×84 | 24 | 12 | 0.34 | 0.75 | 84 |

| W24×104(Sizes Available) | 24 | 12 | 0.4 | 0.88 | 104 |

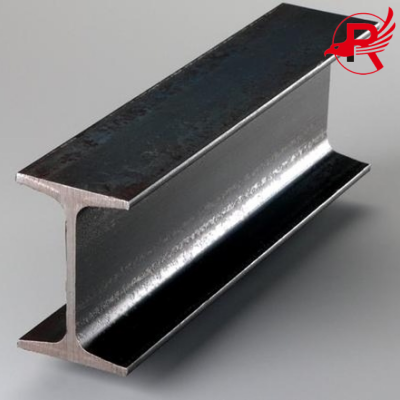

Hot Rolled Black:Standard state

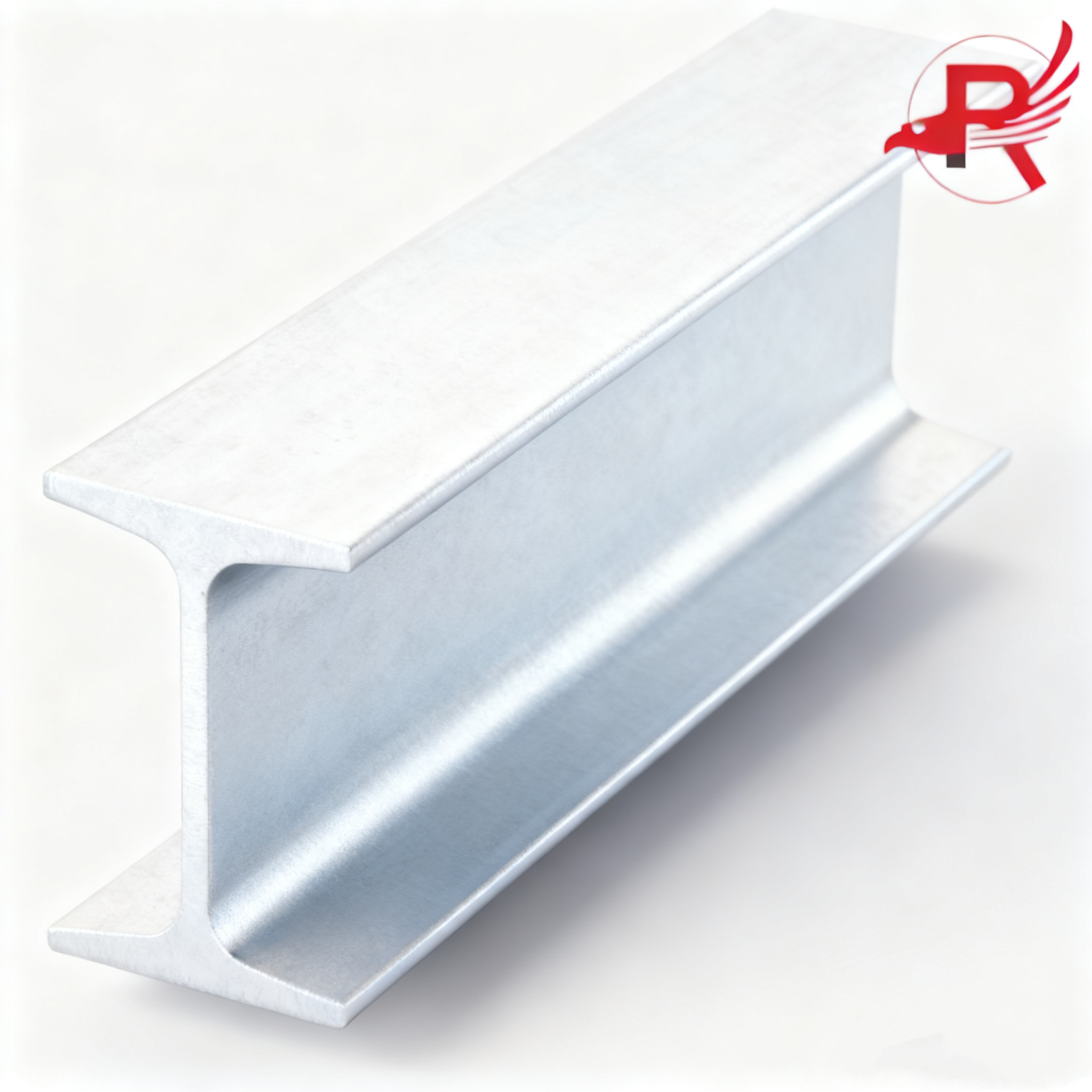

Hot-dip galvanizing: ≥85μm , salt spray test ≥500h

Coating: Epoxy primer + topcoat, dry film thickness ≥ 60μm

Structures: Beams and columns in multi-story buildings, industrial facilities, warehouses and bridges as the main load-bearing elements.

Bridges: I-beams are often used as primary or secondary beams to support traffic loads on bridges.

Heavy Machinery: Steel beams and columns for the support of heavy machinery and steel platforms.

Structural Retrofitting: Strengthen, stabilize, or repair an existing structure to increase its resistance to bending and the magnitude of loads.

Building Structure

Bridge Engineering

Industrial Equipment Support

Structural Reinforcement

1) Branch Office - Spanish-speaking support, customs clearance assistance, etc.

2) Over 5,000 tons of stock in stock, with a wide variety of sizes

3) Inspected by authoritative organizations such as CCIC, SGS, BV, and TUV, with standard seaworthy packaging

Protection and Packaging: I-beam bundles are terrapack wrapped, reinforced with heat-sealed water-proof sheets, and are accompanied by desicant packs to absorb moisture.

Safe Bundling: Bundles are secured with 12-16 mm steel straps, designed to meet US port lifting requirements, applicable for 2-3 tons / bundle.

Transparent Compliance Labeling: Every bale is labelled in English and Spanish with the grade, size, HS code, batch number and test report.

Handling of Large Section: I-beams with a size of 800 mm and above are coated with an industrial anti-rust oil and then wrapped with tarpaulin.

Dependable Logistics: Stable schedules and reliable deliveries are guaranteed by solid alliances with MSK, MSC and COSCO.

Quality Control :All the procedures are carried out under ISO 9001 so that the I-beam can be brought to the site with a perfect condition for the efficient project execution.

Q: Which standards do your I-beams meet for Central America?

A: Our I-beams comply with EN 10025 S235 / S275 / S355 Steel IPE/IPN, widely accepted in Central America. We can also provide products meeting local standards, such as Mexico’s NOM.

Q: What is the delivery time to Panama?

A: Sea freight from Tianjin to Colon Free Trade Zone takes 28–32 days. Total delivery, including production and customs clearance, is 45–60 days. Expedited shipping is also available.

Q: Do you assist with customs clearance?

A: Yes, we work with professional brokers in Central America to handle customs, taxes, and paperwork for smooth delivery.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506