Europen Steel Structure Accessories EN 10025 S275JR Steel Stair

Product Detail

| Parameter | Specification / Details |

|---|---|

| Product Name | EN 10025 S275JR Steel Stair / Structural Steel Staircase for Industrial & Commercial Use |

| Material | S275JR Structural Steel |

| Standards | EN 10025 (European Standard) |

| Dimensions | Width: 600–1200 mm (customizable) Height/Rise: 150–200 mm per step Step Depth/Tread: 250–300 mm Length: 1–6 m per section (customizable) |

| Type | Prefabricated / Modular Steel Stair |

| Surface Treatment | Hot-dip galvanized; painting or powder coating optional; anti-slip tread available |

| Mechanical Properties | Yield Strength: ≥275 MPa Tensile Strength: 430–580 MPa Excellent weldability and toughness |

| Features & Advantages | High-strength structural steel; stable mechanical performance; modular design for fast installation; suitable for indoor and outdoor use; fully customizable dimensions and accessories |

| Applications | Factories, warehouses, commercial buildings, public platforms, mezzanines, access stairs, equipment maintenance areas, processing plants |

| Quality Certification | ISO 9001 |

| Payment Terms | T/T 30% Advance + 70% Balance |

| Delivery Time | 7–15 days |

EN 10025 S275JR Steel Stair Size

| Stair Part | Width (mm) | Height/Rise per Step (mm) | Step Depth/Tread (mm) | Length per Section (m) |

|---|---|---|---|---|

| Standard Section | 600 | 150 | 250 | 1–6 |

| Standard Section | 800 | 160 | 260 | 1–6 |

| Standard Section | 900 | 170 | 270 | 1–6 |

| Standard Section | 1000 | 180 | 280 | 1–6 |

| Standard Section | 1200 | 200 | 300 | 1–6 |

EN 10025 S275JR Steel Stair Customized Content

| Customization Category | Options Available | Description / Range |

|---|---|---|

| Dimensions | Width, Step Height, Tread Depth, Stair Length | Width: 600–1500 mm; Step Height: 150–200 mm; Tread Depth: 250–350 mm; Length: 1–6 m per section (adjustable to project needs) |

| Processing | Drilling, Cutting, Welding, Handrail/Guardrail Installation | Stringers and treads can be drilled or cut to specification; prefabricated welding available; handrails and guardrails can be installed in factory |

| Surface Treatment | Hot-dip galvanizing, Industrial painting, Powder coating, Anti-slip coating | Surface finish selected based on indoor, outdoor, or coastal environment requirements for corrosion and slip protection |

| Marking & Packaging | Custom labels, Project coding, Export packaging | Labels indicate material grade, dimensions, and project info; packaging suitable for container, flatbed, or local delivery |

Surface Finish

Conventional Surfaces

Galvanized Surfaces

Spray Paint Surface

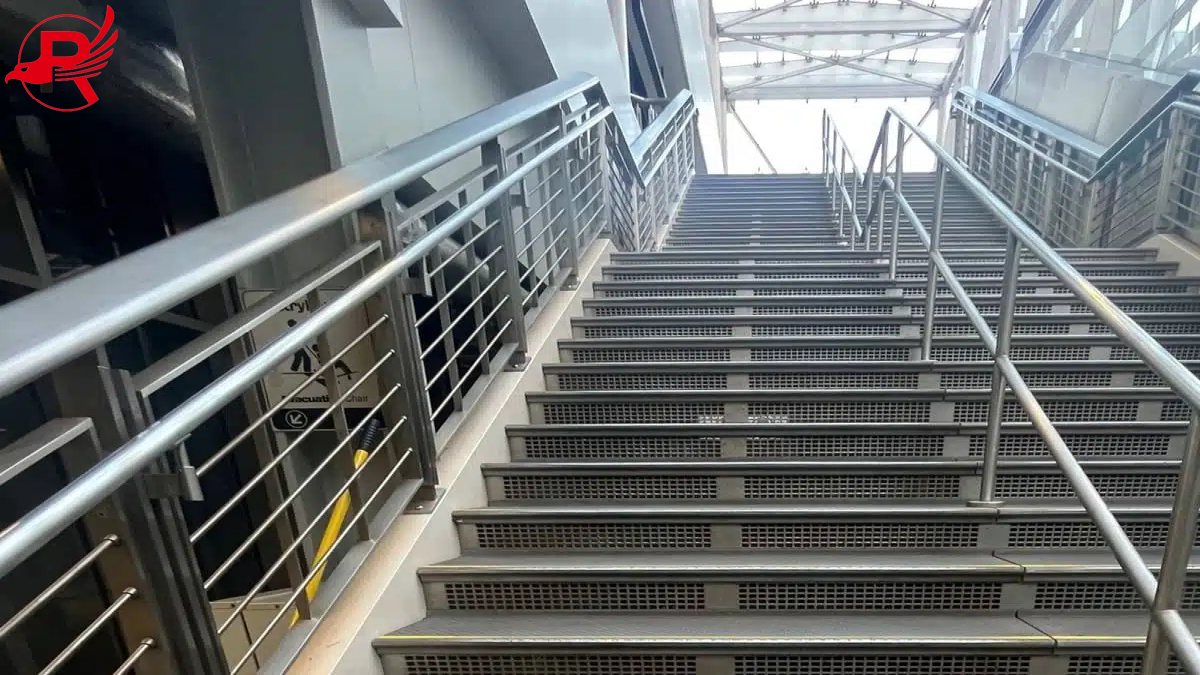

Application

-

Industrial Buildings and Complexes

Ideal for factories, warehouses, and other industrial facilities, providing safe and reliable access to floors, platforms, and equipment while supporting full load capacity. -

Office and Retail Buildings

Suitable for primary or secondary staircases in offices, shopping centers, and hotels, offering a modern, durable, and high-traffic-friendly solution. -

Residential Applications

A cost-effective choice for multi-story and low-rise residential buildings, fully customizable to meet architectural designs and project-specific requirements, including glass and finish options.

Our Advantages

Hardwearing Structural Steel

Made of EN 10025 S275JR steel with processing, high load-bear capacity.

Customizable Design

The stair size, railing spacing and finish can be customized for specific building footprint, project requirements.

Modular Construction

Prefabricated segments for rapid assembly reduce labor and compress construction time.

Safety Compliant

Safety standards for industry,commerce, and home can be complied with such as non-slip treads and optional guardrails.

Improved Surface Protection

With hot-dip galvanizing, industrial painting or powder coating for the indoor, outdoor or marine environment.

Multi-Purpose

Designed for Factory, Business, House, Transit Station, Port, Maintenance Platform.

Technical and Logistic Support

OEM services, such as design customization, project packaging and delivery solutions at client side.

*Send the email to [email protected] to get a quotation for your projects

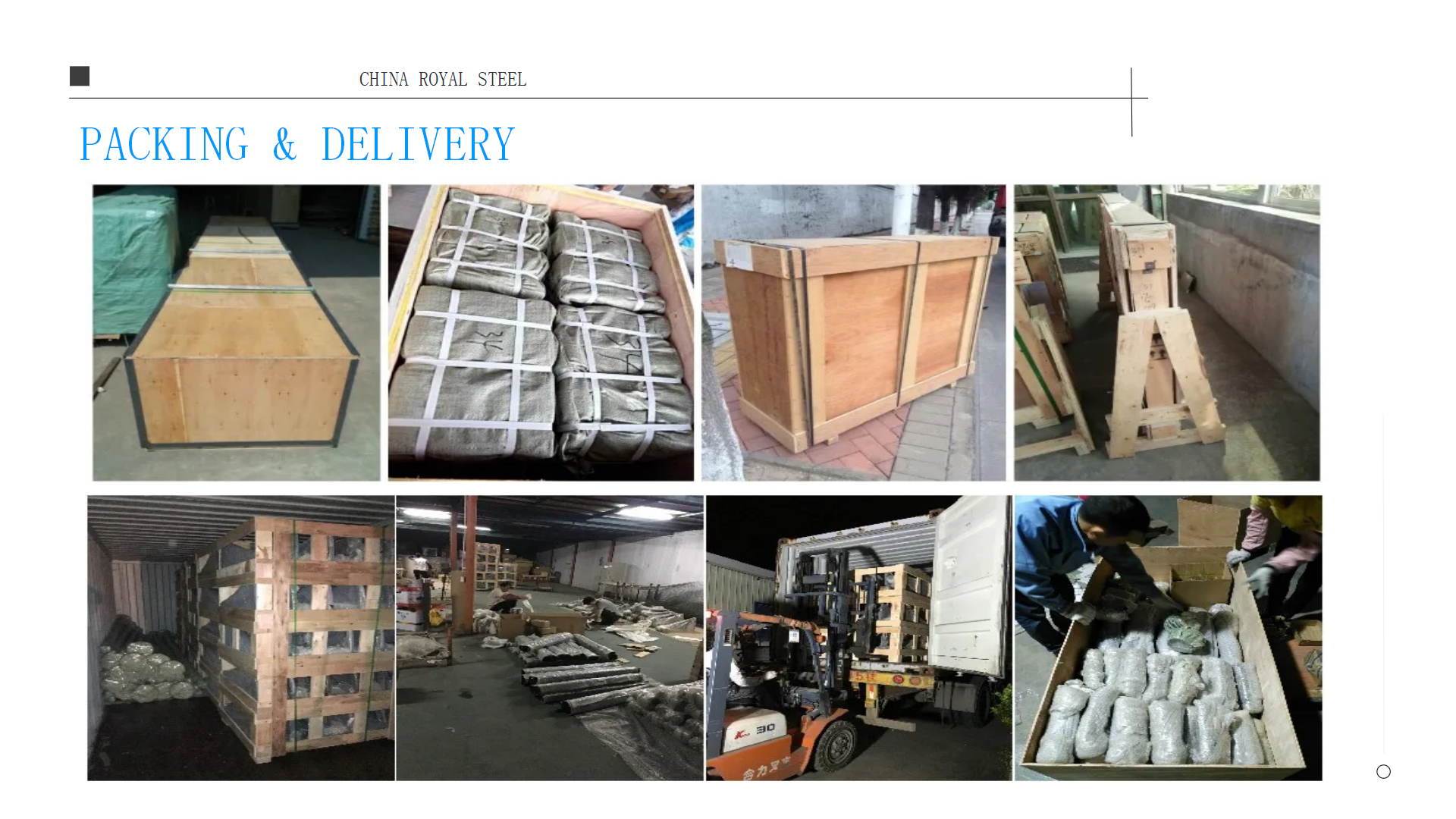

Packaging & Shipping

PACKING

Protection: To protect the module, each stair module is wrapped with tarpaulin and pre-cushioned with foam or carton on both sides to prevent scratching, wetting or rusting while handling.

Stripping: Bundles are strapped with steel or plastic straps to stabilize them during loading, unloading and transportation.

Labeling: English–Spanish bilingual traceability identification label includes material grade, en/astm standard, size, batch reference and inspection/report details.

DELIVERY

Land Transport: Bundles are edge protected and wrapped with slip resistant material for delivery to the job site locally.

Rail Transport: This compact loading method allows multiple stair bundles to be loaded into rail cars, offering an efficient means of long distance transportation.

Sea Freight: Depending on the country of destination and the logistics of the project, the products can be packed in a standard or an open top container.

FAQ

Q1: What material are your steel stairs made of?

A: Our stairs are fabricated from EN 10025 S275JR structural steel, providing enhanced strength, durability, and long-term service life.

Q2: Can the steel stairs be customized?

A: Yes, we offer full customization, including stair width, riser height, tread depth, overall length, handrails, surface finishes, and other project-specific requirements.

Q3: What surface treatments are available?

A: Options include hot-dip galvanizing, epoxy coating, powder coating, and non-slip finishes, suitable for indoor, outdoor, or coastal environments.

Q4: How are the stairs prepared for shipment?

A: Stairs are tightly bundled, securely wrapped, and labeled in English and Spanish. Delivery can be arranged via road, rail, or sea, depending on project logistics and distance.