Factory Good Price High Quality ASTM A572-50 a992 150X150 Wide Flange Beams W14x82 H Beam steel

PRODUCT PRODUCTION PROCESS

The production process for standard H-beams typically includes the following key steps:

Raw Material Preparation: The raw material for H-beams is typically steel billets. These billets are cleaned and heated to prepare for subsequent processing and forming.

Hot Rolling: The preheated billets are fed into a hot rolling mill. In the hot rolling mill, the billets are rolled through multiple rollers, gradually forming the cross-sectional shape of the H-beam.

Cold Working (Optional): In some cases, to improve the precision and surface quality of the H-beam, hot-rolled H-beams may also undergo cold working, such as cold rolling and drawing.

Cutting and Finishing: After rolling and cold working, the H-beams are cut and finished to meet specific dimensions and lengths as required by the customer.

Surface Treatment: The H-beams are cleaned and treated with rust prevention to ensure surface quality and corrosion resistance.

Inspection and Packaging: The finished H-beams undergo quality inspection, including inspections for appearance, dimensional accuracy, and mechanical properties. Once qualified, they are packaged and shipped to the customer.

PRODUCT SIZE

| Designation | Unt Weight kg/m) |

Standard Secional imension mm |

Sectional Ama (cm² |

|||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Designatio | Unit Weight kg/m) |

Standad Sectional Dimersion (mm) |

Sectiona Area (cm²) |

|||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

EN H-Shaped Steel

Grade: EN10034:1997 EN10163-3:2004

Specification:HEA HEB and HEM

Standard: EN

FEATURES

High strength: The cross-sectional shape design of HEA Steel beam gives it high bending strength and load-bearing capacity, making it suitable for large-span structures and heavy-load situations.

Good Stability: The cross-sectional shape of H-beams provides excellent stability under pressure and tension, contributing to structural stability and safety.

Easy Construction: The design of H-beams makes them easy to connect and install during construction, which improves project progress and efficiency.

High Resource Utilization: The design of H-beams fully utilizes the properties of steel, reduces material waste, and contributes to resource conservation and environmental protection.

Wide Application: H-beams are suitable for various building structures, bridges, machinery manufacturing, and other fields, and have broad application prospects.

Overall, external standard H-beams are characterized by high strength, good stability, and easy construction. They are an important structural steel material and are widely used in various engineering fields.

PRODUCT INSPECTION

The requirements for Astm A572-50 Wide Flange Beams inspection mainly include the following aspects:

Appearance Quality: The appearance quality of Heb 150 H-beams must comply with relevant standards and order requirements. The surface should be smooth and flat, free of obvious defects such as dents, scratches, and rust.

Geometric Dimensions: The length, width, height, web thickness, and flange thickness of H-beams must comply with relevant standards and order requirements.

Bend: The bend of H-beams must comply with relevant standards and order requirements. This can be determined by measuring the parallelism of the two ends of the H-beam or using a bend gauge.

Torsion: The torsion of H-beams must comply with relevant standards and order requirements. This can be determined by measuring the verticality of the sides of the H-beam or using a torsion gauge.

Weight Deviation: The weight of H-beams must comply with relevant standards and order requirements. Weight deviation can be determined by weighing.

Chemical Composition: If H-beams require welding or other processing, their chemical composition must comply with relevant standards and order requirements.

Mechanical Properties: The mechanical properties of H-beams must comply with relevant standards and order requirements, including tensile strength, yield point, and elongation. Nondestructive Testing: If H-beams require nondestructive testing, they should be conducted in accordance with relevant standards and order requirements to ensure their inherent quality.

Packaging and Marking: H-beam packaging and marking should comply with relevant standards and order requirements to facilitate transportation and storage.

In summary, the above requirements should be fully considered when inspecting H-beams to ensure their quality meets relevant standards and order requirements, providing users with the highest quality H-beam products.

PRODUCT APPLICATION

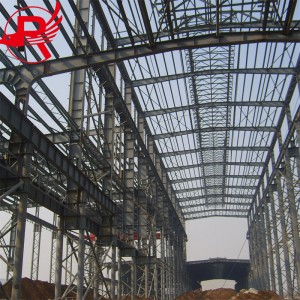

External standard H-beams are widely used in the construction and engineering fields, including but not limited to the following aspects:

Structural engineering, bridge engineering, machinery manufacturing, shipbuilding, steel structure construction,

PACKAGING AND SHIPPING

Packaging and transportation of external standard H-beams usually require following the following steps:

Packaging: H-beams are typically packaged according to customer specifications to protect their surfaces from damage. Common packaging methods include bare packaging, wooden pallet packaging, and plastic packaging. Ensure that the H-beams are free of scratches and corrosion during packaging.

Labeling: Clearly label the packaging with product information, such as model, specifications, and quantity, for easy identification and management.

Loading: During loading and transportation, ensure that the packaged H-beams are free from collisions and crushing to prevent damage.

Transportation: Select appropriate transportation methods, such as trucks or rail, based on customer requirements and transportation distance.

Unloading: Upon arrival at the destination, unload carefully to prevent damage to the H-beams.

Storage: Store H-beams in a dry, well-ventilated warehouse to avoid moisture and other adverse effects.

COMPANY STRENGTH

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.