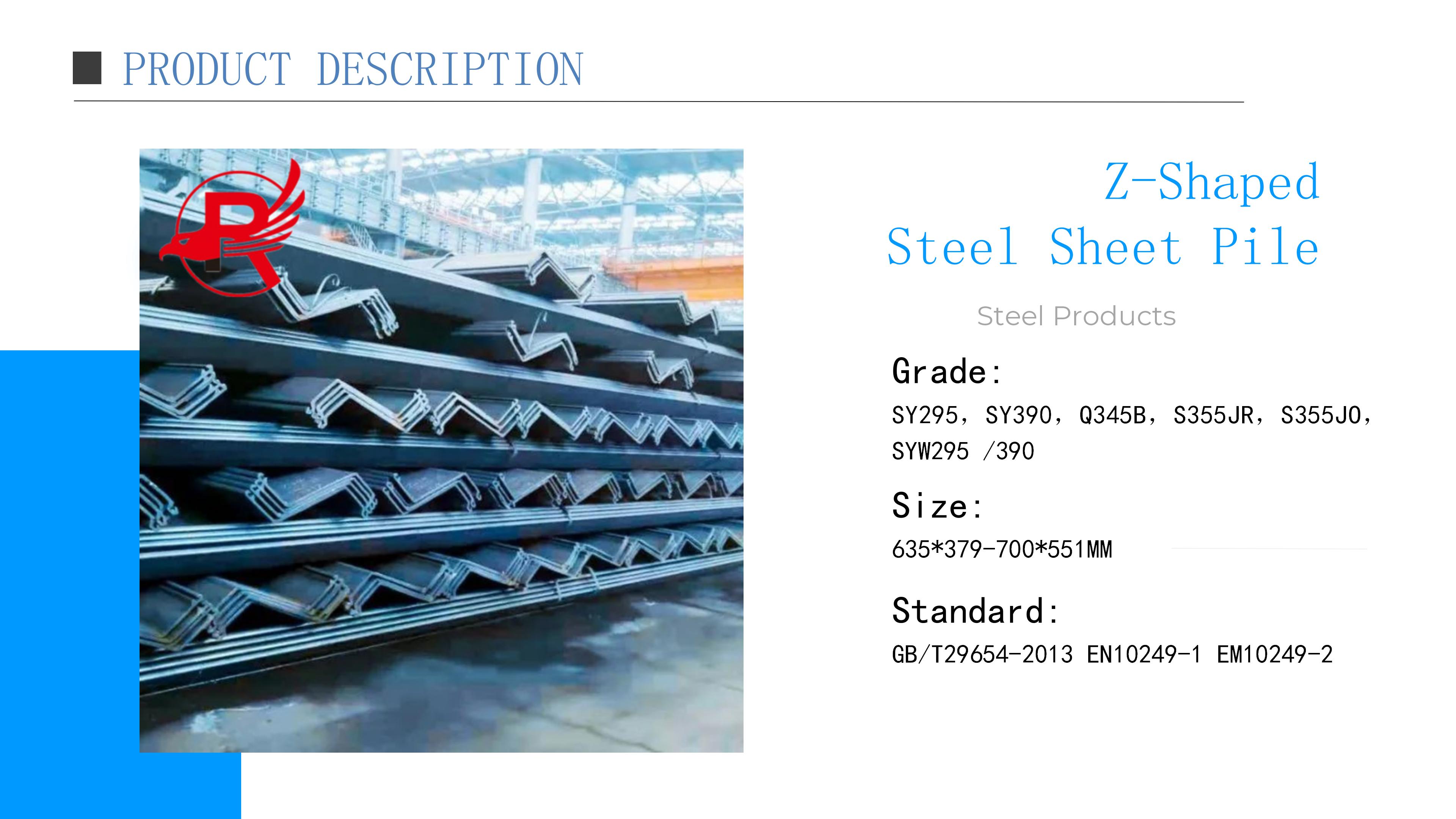

Factory Price Cold Formed Z Type Az36 Metal Sheet Piling Steel Sheet Pile

|

SPECIFICATIONS FOR Z SHEET PILE |

|

| 1. Size | 1) 635*379—700*551mm |

| 2)Wall Thickness:4—16MM | |

| 3)Z type sheet pile | |

| 2. Standard: | GB/T29654-2013 EN10249-1 |

| 3.Material | Q235B Q345B S235 S240 SY295 S355 S340 Az18 Az36 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)rolling stock |

| 2)Building steel structure | |

| 3Cable tray | |

| 6. Coating: | 1) Bared2) Black Painted (varnish coating)3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | Z type sheet pile |

| 9. Section Shape: | Z |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Free for oiled&marking3) All goods can be checked by third party inspection before shipment |

*Send the email to [email protected] to get a quotation for your projects

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Others available on request

Length

35.0m maximum but any project specific length can be produced

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

Grip Plate

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

Benaim added: “Reduction of the number of piles High strength single piles Z-type piles’ high-performance cross-section minimizes the number of piles required to be driven which contributes to construction work acceleration.

Suitable for Deep and Large Scale Projects: Suitable for challenging projects including deep-sea docks, large-sized shipyards, bridge cofferdams and foundation pits deeper than 10–15 m.

High Wall Rigidity Is Constructed: The continuous wall provides high rigidity and good deformation control.

PRODUCT PRODUCTION PROCESS

The production process of hot-rolled Z-shaped steel sheet pile usually includes the following steps:

Preparation of Raw Material: Good quality steel is selected and segregated as per production norms after inspection.

Heating & Rolling: steel is heated and rolled into the Z shape, with several passes over the rolling mill to come close to the final size and shape.

Cooling & Forming : Rolls of steel are cooled to set their structure, and subsequently formed and trimmed to provide right geometrics and smooth surface along the length.

Inspection & Packing: the products are quality checked for look, size and chemical composition and then packed.

Transport: End-bearing piles are block loaded to transportation, with attention paid to avoid any injuries inflicted in shipping.

*Send the email to [email protected] to get a quotation for your projects

Types of Z-piles

AZ Sheet Pile: AZ steel sheet piles are high strength Us most efficient form of support material that also shares easy construction conditions with the shape of the U profile piles. Their unique asymmetric AZ cross-section is their core feature. Various types of az 18 sheet pile and az 36 sheet pile has been in developing and manufacturing for years and the most commonly used are az 18 sheet pile and az 36 sheet pile in engineeringBy arranging flanges with different lengths on two sides of a wide web, they maximize the material from the neutral axis, thus attaining a very high area module.

NZ Sheet Pile: NZ steel sections provide the greatest versatility and best strength to weight ratio among local sheet piles. The two also represent the widest section widths among local sheet piles which means less driven piles. The Larsen interlock is well waterproofed, and all NZ sections interlock with each other.

PZ Sheet Pile: PZ sheet piles are more popular for their ball-and-socket interlocking design. With PZ22 Sheet Pile’s compact design and sturdy interlocking system, they are the best solution for multiple uses. The ball-and-socket engagement pattern can also be inverted up to 10 degrees for rotation when making turns at building sites.

SCZ/SKZ Sheet Pile: SCZ/SKZ piles are cold-formed steel sheet piles manufactured from coils. SCZ/SKZ profiles are generally wider and more effective than hot rolled sheet steel, thus higher sway angle can be achieved. The small and flexible rolling line can provide a series of possibilities. SCZ/SKZ is a range of SCZ/SKZ profiles in five different dimensions and thickness.

APPLICATION

Port & Marine Engineering: Dredging, seawalls, groynes & quays.

Large Bridge Foundations: Cofferdams for bridge piers.

Deep Foundation Pit Support: Urban high-rise building foundations, subway stations, and other deep excavations.

Heavy-Duty Retaining Walls: Permanent or temporary walls holding back high lateral earth pressure.

Hydraulic Engineering: Water-retentive and seepage-proof structures (sluice-gates, pumping stations).

PACKAGING AND SHIPPING

Container transport: Suitable for small piles; economical and not reliant on weather or roads. Large piles may not fit in the container.

Bulk Transport: The piles are transported unpackaged to save cost, but is necessary to take lashing and handle carefully to avoid damage.

Flatbed Transport: Best for large stacks, flatbed, telescopic or low-bed trucks are used subject to the dimension and weights.

Rail Transport: Utilizes dedicated railcars for rapid, economical, and safe transportation, with a focus on load security and speed management.

COMPANY STRENGTH

Made in China, First-Class Service, Cutting-Edge Quality, Worldwide Reputation

-

Scale: Large steel mills and supply chain enable cost-efficient production and integrated services.

-

Product Variety: Wide range of steel products, including structural steel, rails, sheet piles, PV mounts, channels, and silicon steel coils, offering flexible selection.

-

Stable Supply: Reliable production lines ensure consistent delivery, even for large orders.

-

Brand Strength: Strong market presence and recognized reputation.

-

Comprehensive Service: Full solutions for customization, production, and logistics.

-

Competitive Pricing: High-quality steel at reasonable prices.

7.We are hot rolled and cold formed sheet pile factory.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

Q1: What does your company produce?

A1: We manufacture steel sheet piles, rails, silicon steel, shaped steel, and related products.

Q2: What is your delivery time?

A2: 5–10 days for in-stock items; 15–20 days for out-of-stock items, depending on quantity.

Q3: What are your company’s advantages?

A3: We have a professional team and specialized production lines.

Q4: Are you a trading company or a manufacturer?

A4: We are a factory.

Q5: What are your payment terms?

A5: Orders ≤ $1,000: 100% in advance. Orders ≥ $1,000: 30% T/T in advance.