ASTM Equal Angle Steel Galvanized Unequal Angle Great price and high quality

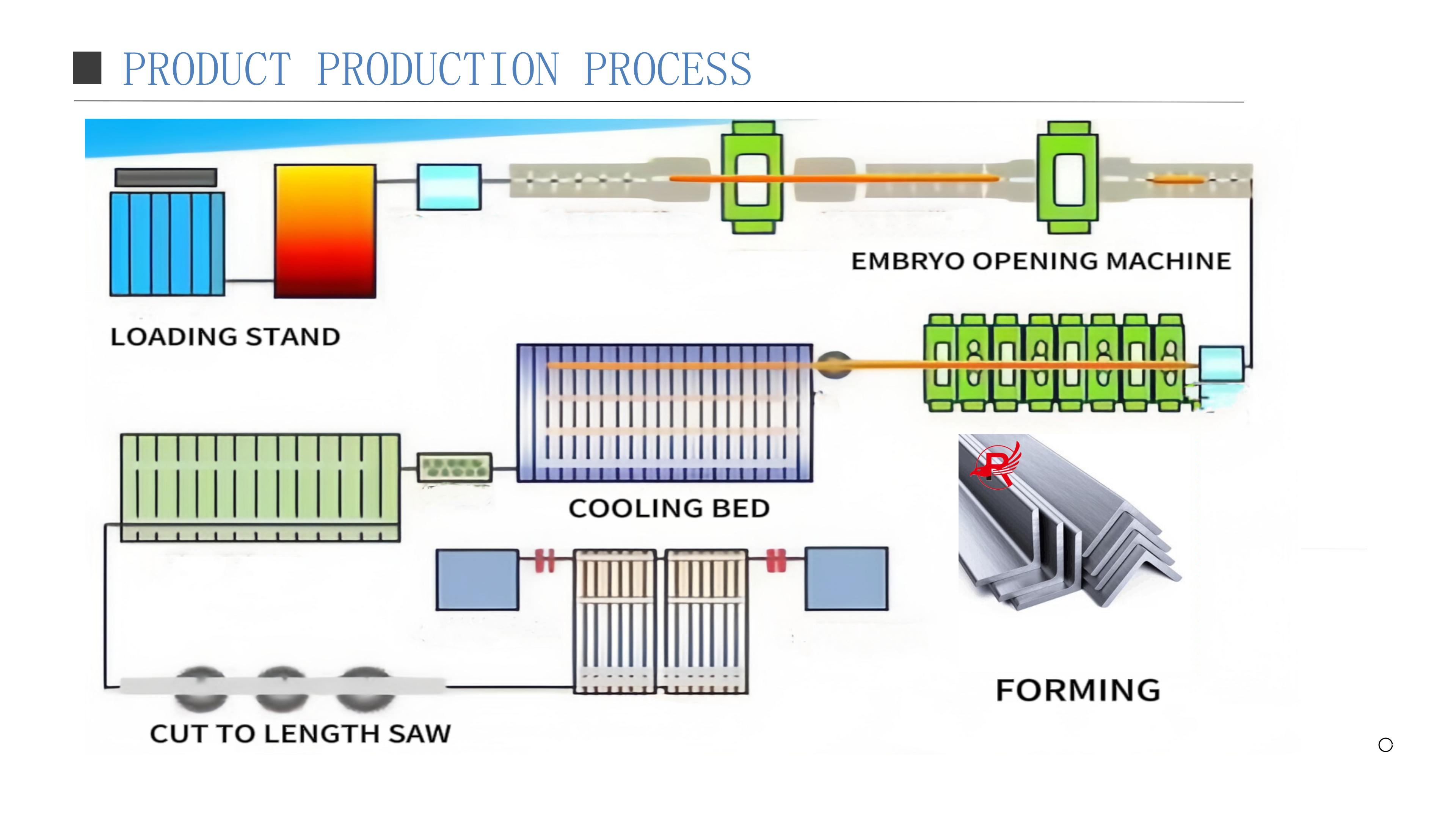

PRODUCT PRODUCTION PROCESS

The production process of angle steel usually includes the following steps:

Preparation of Material: Choose the steel plates which conforms to the design standard, the material is usually hot-rolled or cold-rolled based on your project need.

Cutting: Cut the steel plates to make the blanks.

Soaking: Soaking steel blanks in a furnace for heating can enhance fluidity and workability.

Cold Bending/Forming: Using a cold bending machine, the pre-warmed blanks are rolled and bent into the cross-sectional form of unequal angle steel.

Cut-to-Length: Cut the cold-formed unequal angle steel to the desired lengths.

Leveling & Straightening: The product should be straight and accurate in dimension.

Surface Treatment: Follow a process, such as rust removal or painting, which provides corrosion protection.

Inspection of the finished goods for surface, size and quality in general.

Packing & Storage: Pack the qualified unequal angle steel, label with product information and put it in stock for ship.

Product Detail

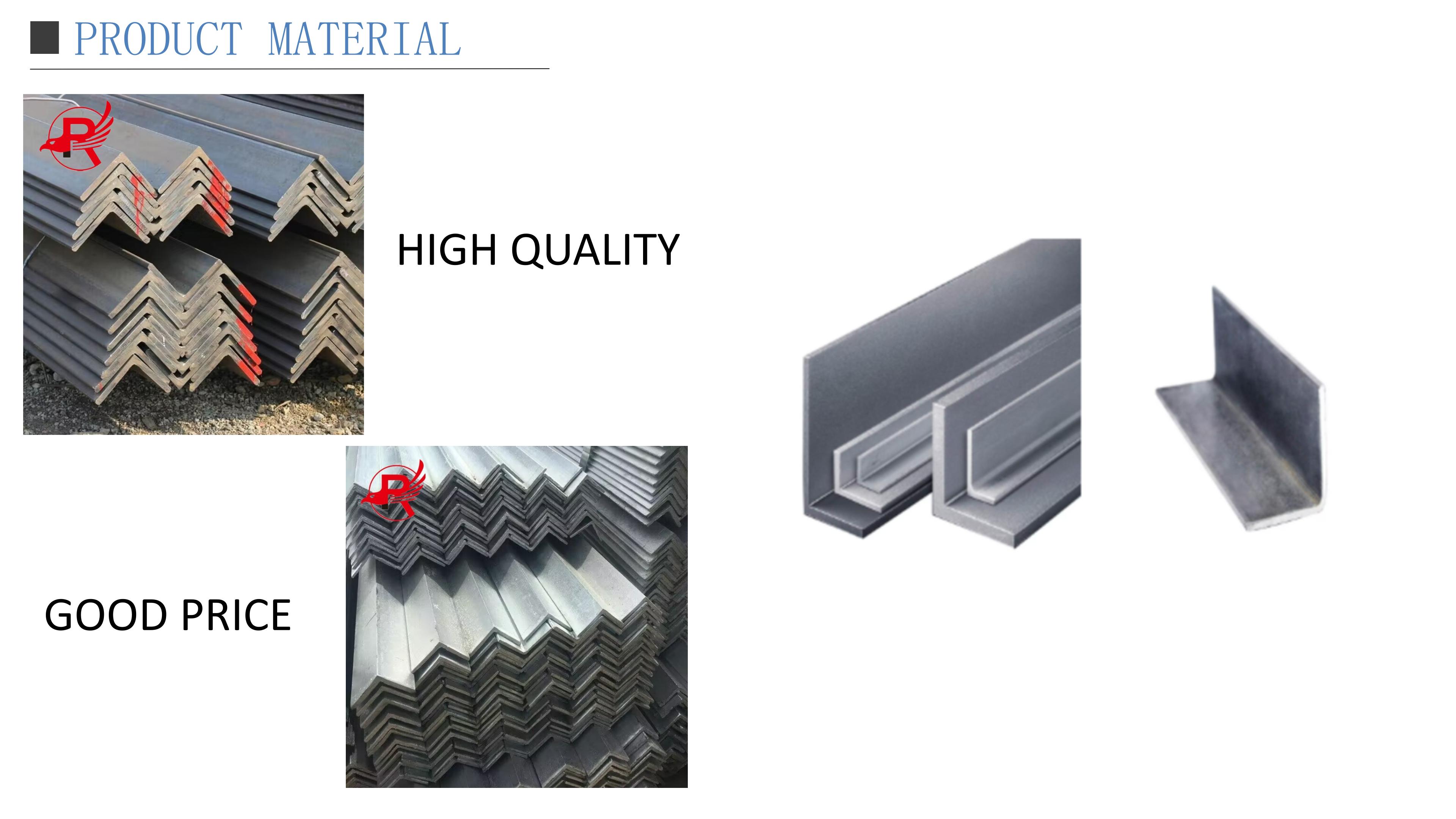

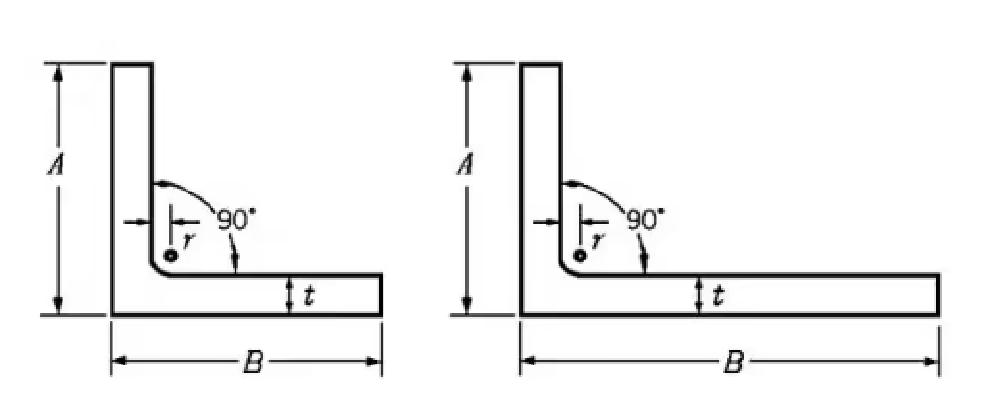

Equal and unequal carbon steel angle bars are common structural steel components used in construction, manufacturing, and engineering projects. Both types are L-shaped and made from carbon steel, but they differ in the dimensions of their legs.

Equal Angle Bars: Two legs are equal length at 90°, perfect for framework, brackets and reinforcements.

Unequal Angle Bars: The leg has a longer length, forming an incident angle, useful for variable support configurations or specific load conditions.

Both are available in standard sized, can be fabricated and machined easily and the strength of the carbon steel makes them suitable for use in structural applications.

|

item

|

value

|

|

Standard

|

ASTM, AiSi, DIN, EN, GB, JIS

|

|

Place of Origin

|

China

|

|

Type

|

Equal and Unequal angle bar

|

|

Application

|

structure、Industrial building、Industry/Chemical Equipment/Kitchen

|

|

Tolerance

|

±3%

|

|

Processing Service

|

Bending, Welding, Punching, Decoiling, Cutting

|

|

Alloy Or Not

|

Non-Alloy

|

|

thickness

|

0.5mm-10mm

|

|

Delivery Time

|

8-14 days

|

|

Product name

|

Hot Rolled Steel Angle Bar

|

|

Processing Service

|

Cutting

|

|

Shape

|

Equal Unequal

|

|

MOQ

|

1 Ton

|

|

Material

|

Q235/Q345/SS400/ST37-2/ST52/Q420/Q460/S235JR

|

|

Length

|

6m-12m

|

|

PRICE TERM

|

CIF CFR FOB EX-WORK

|

|

Packing

|

Standard Packing

|

|

Keywords

|

Angel Steel Bar

|

| Equal angle steel | |||||||

| Size | Weight | Size | Weight | Size | Weight | Size | Weight |

| (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) |

| 20*3 | 0.889 | 56*3 | 2.648 | 80*7 | 8.525 | 12*10 | 19.133 |

| 20*4 | 1.145 | 56*4 | 3.489 | 80*8 | 9.658 | 125*12 | 22.696 |

| 25*3 | 1.124 | 56*5 | 4.337 | 80*10 | 11.874 | 12*14 | 26.193 |

| 25*4 | 1.459 | 56*6 | 5.168 | 90*6 | 8.35 | 140*10 | 21.488 |

| 30*3 | 1.373 | 63*4 | 3.907 | 90*7 | 9.656 | 140*12 | 25.522 |

| 30*4 | 1.786 | 63*5 | 4.822 | 90*8 | 10.946 | 140*14 | 29.49 |

| 36*3 | 1.656 | 63*6 | 5.721 | 90*10 | 13.476 | 140*16 | 33.393 |

| 36*4 | 2.163 | 63*8 | 7.469 | 90*12 | 15.94 | 160*10 | 24.729 |

| 36*5 | 2.654 | 63*10 | 9.151 | 100*6 | 9.366 | 160*12 | 29.391 |

| 40*2.5 | 2.306 | 70*4 | 4.372 | 100*7 | 10.83 | 160*14 | 33.987 |

| 40*3 | 1.852 | 70*5 | 5.697 | 100*8 | 12.276 | 160*16 | 38.518 |

| 40*4 | 2.422 | 70*6 | 6.406 | 100*10 | 15.12 | 180*12 | 33.159 |

| 40*5 | 2.976 | 70*7 | 7.398 | 100*12 | 17.898 | 180*14 | 38.383 |

| 45*3 | 2.088 | 70*8 | 8.373 | 100*14 | 20.611 | 180*16 | 43.542 |

| 45*4 | 2.736 | 75*5 | 5.818 | 100*16 | 23.257 | 180*18 | 48.634 |

| 45*5 | 3.369 | 75*6 | 6.905 | 110*7 | 11.928 | 200*14 | 42.894 |

| 45*6 | 3.985 | 75*7 | 7.976 | 110*8 | 13.532 | 200*16 | 48.68 |

| 50*3 | 2.332 | 75*8 | 9.03 | 110*10 | 16.69 | 200*18 | 54.401 |

| 50*4 | 3.059 | 75*10 | 11.089 | 110*12 | 19.782 | 200*20 | 60.056 |

| 50*5 | 3.77 | 80*5 | 6.211 | 110*14 | 22.809 | 200*24 | 71.168 |

| 50*6 | 4.456 | 80*6 | 7.376 | 125*8 | 15.504 | ||

ASTM Equal Angle Steel

Grade:A36、A709、A572

Size:20x20mm-250x250mm

Standard:ASTM A36/A6M-14

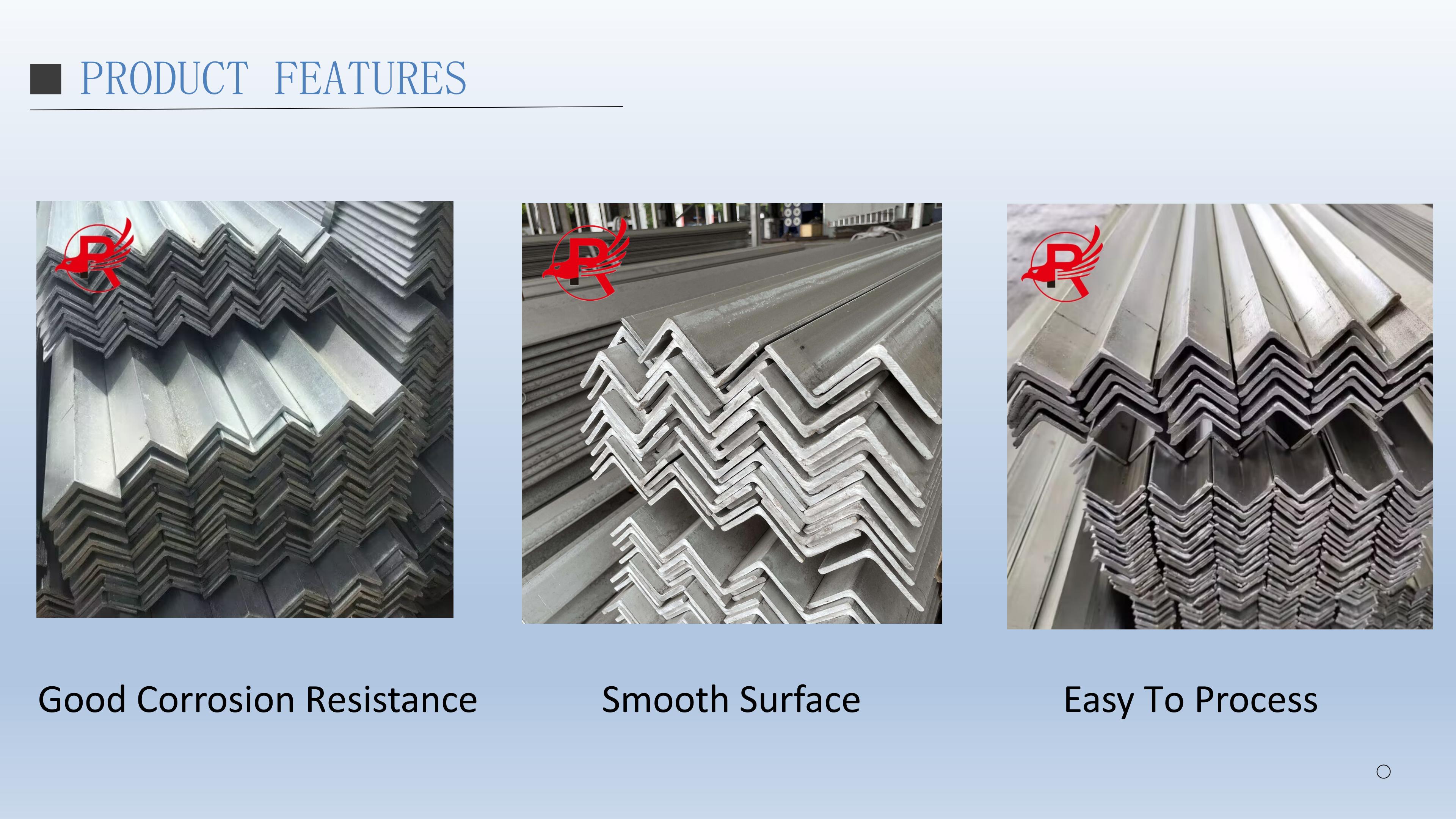

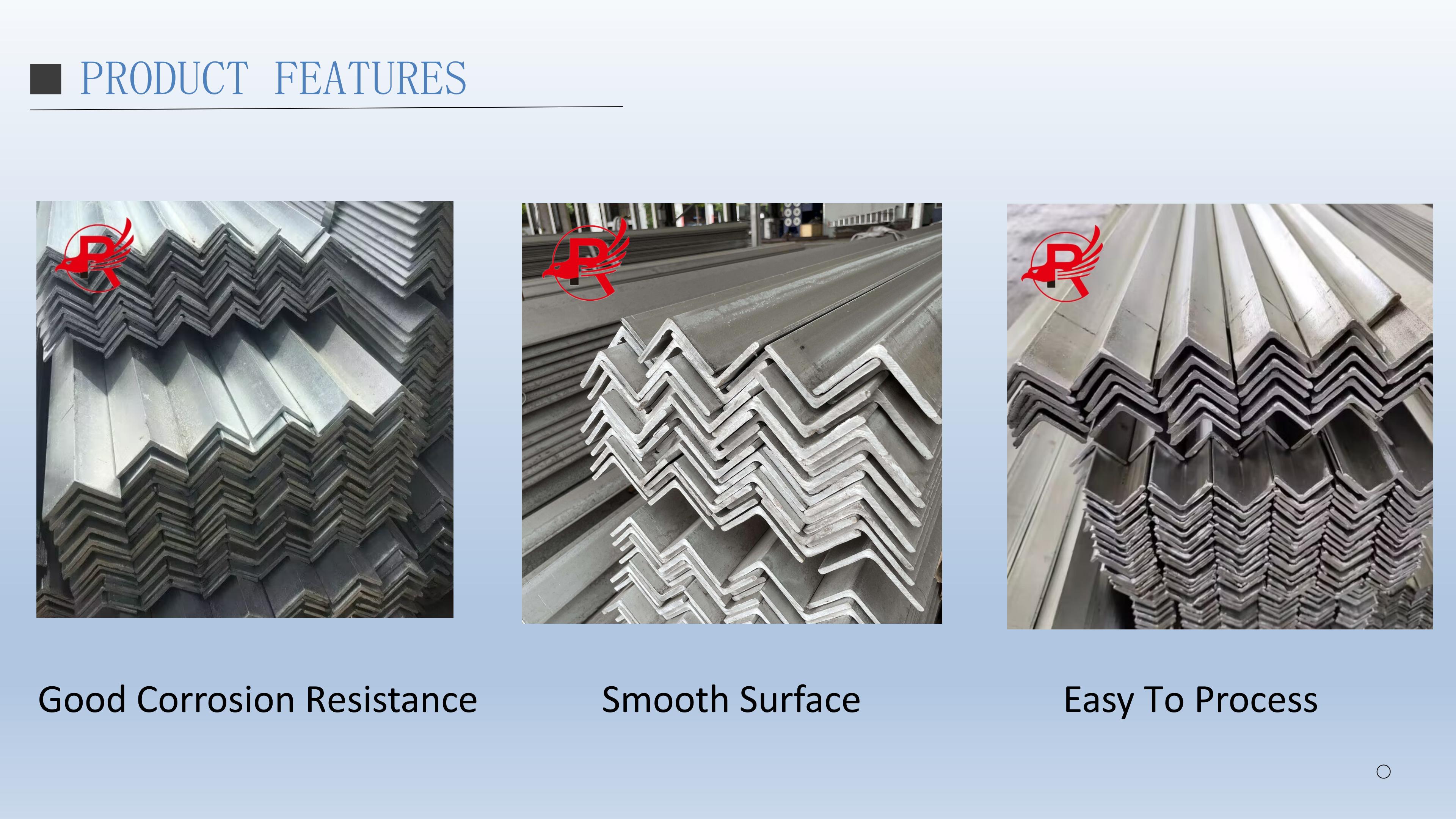

Features

Mild Equal Angle Steel Bars (also called angle iron or L-shaped steel) are widely used in construction and industrial projects due to their versatility and structural performance.

-

Right Angle: Legs of equal length form a 90° angle, suitable for framing, bracing, and supports.

-

Strength: Made from mild steel, offering good rigidity and load-bearing capacity.

-

Weldability: Easily welded for flexible fabrication.

-

Machinability: Can be cut or machined to specific lengths and angles.

-

Corrosion Resistance: May require protective coatings in harsh environments.

-

Versatility: Applied in building frames, structural reinforcements, and various industrial components.

Application

Lightweight Construction: Equal angle bars are employed in building and civil work for frames, braces and supports, in the manufacture of machinery, equipment and storage systems and in architectural work for brackets, corner guards and decorative features.

Machinability and weldability: The products can be cut machined and welded easily for custom design and installation.

Strength and Load-Bearing : The symmetrical L-shape and robust design results in higher load capacity and structural stability.

Finish & Coatings: The product bear the finish of mill or with protective coatings for enhance the durability and corrosion by environment of application.

Packaging & Shipping

The delivery of angle steel bars is safe if packaged in right way. Some of the methods are as follows:

Bundling: Bars are tied in bundles with steel straps or wires to prevent movement or damage during transportation.

Protective Coatings: The bars are protected from exposure to moisture, dust and other contaminates with plastic, paper or other similar materials.

Wooden crates or skids: They give a firm foundation and more protection from rough handling.

Labeling: Packages are labeled with the dimensions, weight, grade of steel and special handling instructions to facilitate their identification.

Secure Positioning: Bars are snugly packed to stay in place making for safe transportation.

CUSTOMERS VISIT

FAQ

1.How to request a quotation?

Leave us a message and we will get back to you as soon as possible!

2.Can the delivery be guaranteed?

Yes, we guarantee the delivery on time and our products of high quality.

3.Could I get the samples?

Yes, samples are free normally and can be produced according to your sample or drawings.

4.Terms of payment?

Typical terms 30% deposit, balance against B/L. EXW, FOB, CFR, CIF.

5.Inspection by a third party?

Yes, third party inspection is accepted.

6.How to trust your company?

We are experienced golden supplier for many years in steel in Tianjin and all the ways of verification are welcome.