The H-beams and columns are submerged arc welded, the gusset plate is arc welded manually and the thin walled sections are welded with co2 gas.

GB Q235B Q345B Steel Structure Building Steel Structure

APPLICATION

Steel Building :A steel building is a durable, high-strength structure widely used in residential and commercial projects.

Steel Structure House: A steel structure house is a modern, durable, and eco-friendly home built with a steel frame for superior strength and longevity.

Steel Structure Warehouse: A steel structure warehouse is a large, durable, and cost-efficient building made with steel frames, ideal for storage, logistics, and industrial use.

Steel Structure Industrial Building:A steel structure industrial building is a durable and efficient facility for manufacturing and industrial use.

PRODUCT DETAIL

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation Points |

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Main beam for roof/wall load-bearing | Seismic nodes use bolted flanges instead of brittle welds, making them lighter and easier to transport. |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Supports frame and floor loads | Seismic base plate connectors are hot-dip galvanized (≥85 μm) for basic corrosion protection in humid conditions. |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Load-bearing for industrial crane operation | Heavy-duty cranes (5–20 tons) feature end beams with shear-resistant plates. |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins: C12×20–C16×31 (hot-dip galvanized) with center distance of 1.5–2m is applicable for the installation of color-coated steel sheet and has the anti-typhoon up to level 12 ability.

Wall Purlins: Z10×20-Z14×26 (anti-corrosion painted) with ventilation holes to reduce condensation in tropical factory environment.

Support System: A bracing (Φ12–Φ16 hot-dip galvanized round steel) and corner brace (L50×5 steel angles) enhances lateral stiffness and ensures excellent performance under winds up to hurricane.

3. Supporting auxiliary products (localized construction adaptation)

1.Integrated panels: The galvanized steel plates (10–20 mm) have a load-bearing capacity equivalent to at least that of conventional foundation slabs in Central America.

2.Connectors: High-strength, class 8.8 galvanized bolts; no welding required.

3.Coatings: Water-based intumescent paint (≥1.5 hours) and anti-corrosive acrylic paint with UV protection (lifespan ≥10 years), compliant with national environmental regulations.

STEEL STRUCTURE PROCESSING

| Processing Method | Processing Machines | Processing |

| Cutting | CNC plasma/flame cutting machines, shearing machines | CNC plasma/flame cutting (for steel plates/sections), shearing (for thin steel plates), with controlled dimensional accuracy |

| Forming | Cold bending machine, press brake, rolling machine | Cold bending (for C/Z purlins), bending (for gutters/edge trimming), rolling (for round support bars) |

| Welding | Submerged arc welding machine, manual arc welder, CO₂ gas-shielded welder |

|

| Holemaking | CNC drilling machine, punching machine | CNC drilled for bolt holes and punched for short runs, guaranteeing hole size and location. |

| Treatment | Shot blasting/sand blasting machine, grinder, hot-dip galvanizing line | Rust removal (shot blasting/sand blasting), weld grinding (for deburring), hot-dip galvanizing (for bolts/supports) |

| Assembly | Assembly platform, measuring fixtures | Pre-assemble components (columns + beams + supports), disassemble after dimensional verification for shipment |

STEEL STRUCTURE TESTING

| 1. Salt spray test (core corrosion test) Meets ASTM B117 / ISO 11997-1 for coastal corrosion resistance in Central America. |

2. Adhesion test Crosshatch (ISO 2409 / ASTM D3359) and Pull-off (ISO 4624 / ASTM D4541) ensure coating adhesion and peel strength. |

3. Humidity and heat resistance test ASTM D2247 (40 °C / 95% RH) prevents blistering and cracking in rain. |

| 4. UV aging test ASTM G154 protects against UV fading and chalking. |

5. Film thickness test Dry (ASTM D7091) and Wet (ASTM D1212) measurements ensure corrosion protection. |

6. Impact strength test ASTM D2794 (drop hammer) safeguards coatings during transport and storage. |

SURFACE TREATMENT

Surface Treatment Display: Epoxy zinc-rich coating, galvanized (hot dip galvanized layer thickness ≥85μm service life can reach 15-20 years), black oiled, etc.

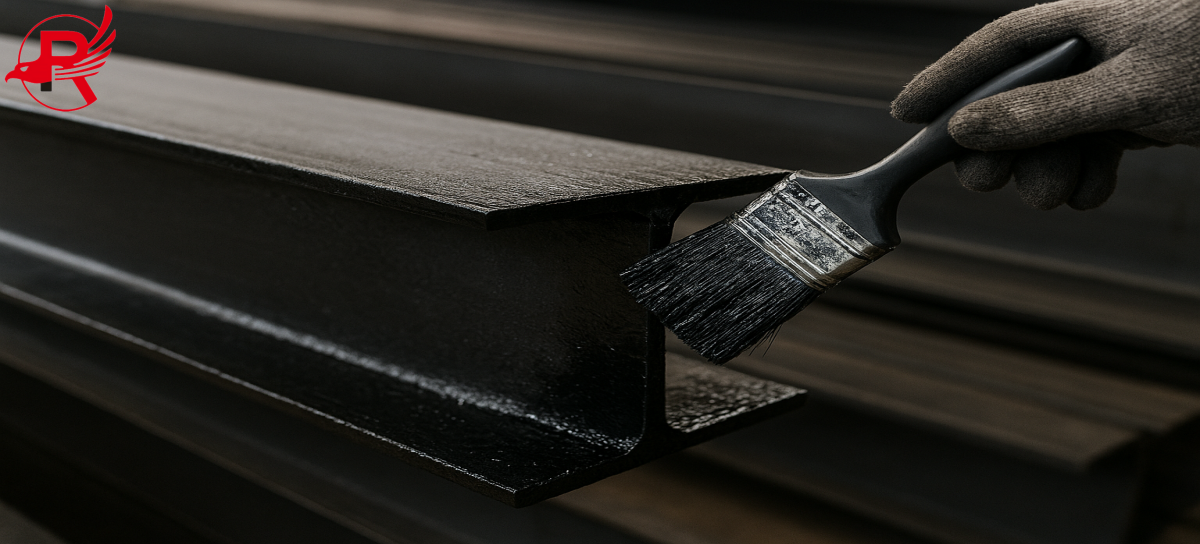

Black Oiled

Galvanized

Epoxy Zinc-rich Coating

PACKAGING AND SHIPPING

Packaging:

The steel structure is securely packed for safe delivery: large components are wrapped in waterproof sheets, while smaller parts are assembled, labeled, and stored in wooden boxes for easy unloading and assembly.

Transportation:

Steel structures can be transported by container or bulk ship, with large components secured using steel straps and wooden wedges to meet delivery standards.

OUR ADVANTAGES

1. Overseas Branch & Spanish Language Support

We have overseas branches with Spanish-speaking teams to provide full communication support for Latin American and European clients.

Our team assists with customs clearance, documentation, and logistics coordination, ensuring smooth delivery and faster import procedures.

2. Ready Stock for Fast Delivery

We maintain sufficient inventory of standard steel structure materials, including H beams, I beams, and structural components.

This enables shorter lead times, ensuring customers receive products quickly and reliably for urgent projects.

3.Professional Packaging

All products are packed with standard seaworthy packaging — steel frame bundling, waterproof wrapping, and edge protection.

This ensures safe loading, long-distance transport stability, and damage-free arrival at the destination port.

4.Efficient Shipping & Delivery

We work closely with reliable shipping partners and provide flexible delivery terms such as FOB, CIF, and DDP.

Whether by sea, rail, we guarantee on-time shipment and efficient logistics tracking services.

FAQ

Regarding Material Quality

Q: What are the quality standards of your steel structures?

A: Our steel is in accordance with American standards such as ASTM A36 for (carbon structural steel) and ASTM A588 (high weather resistant steel for aggressive environments).

Q: How to test the quality of steel?

A: We purchase from a few good mills and test all material on receipt, both chemical, mechanical, and non destructive tests (radiography, ultrasonic, magnetic particle and visual) to the extent that is required by applicable standards.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506