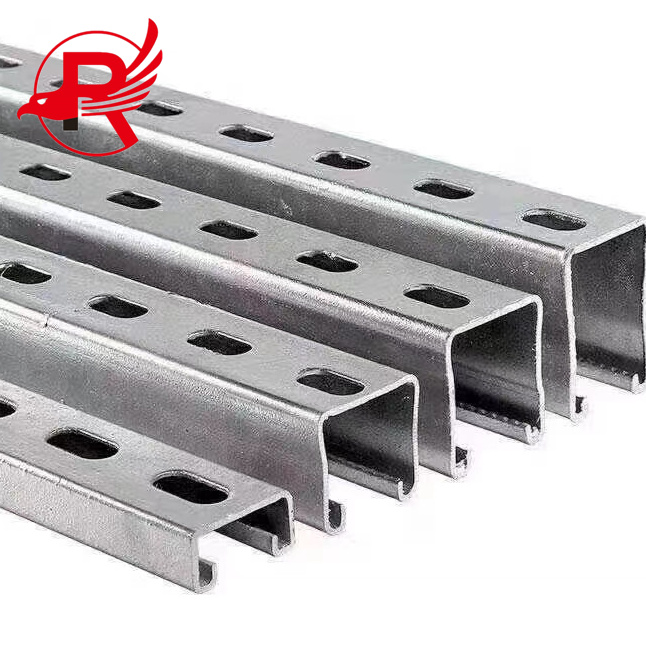

Golden Supplier Reasonable Price Customized U-Shapped Carbon Steel Strut Channel

C Channel Structural Steel can be divided into fixed, adjustable and automatic tracking. The fixed bracket is fixed on the foundation by means of embedded parts, etc., which is suitable for installation needs of different angles;

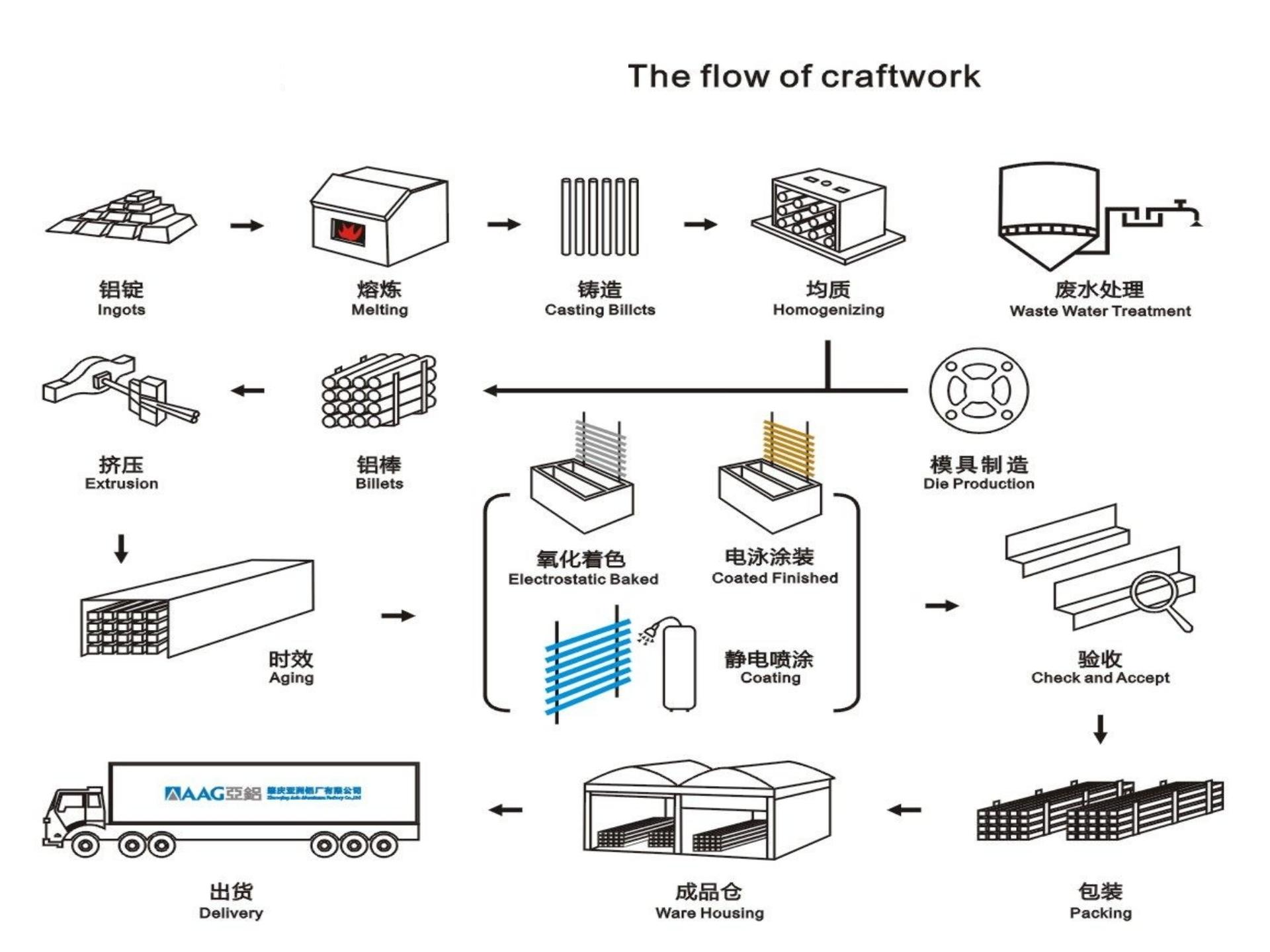

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

| Item | Specifications |

|---|---|

| Material | Q195 / Q235 / SS304 / SS316 / Aluminum |

| Thickness | 1.5 / 1.9 / 2.0 / 2.5 / 2.7 mm (12GA / 14GA / 16GA / 0.079'' / 0.098'') |

| Cross Section | 41×21, 41×41, 41×62, 41×82 mm; slotted or plain (1-5/8''×1-5/8'', 1-5/8''×13/16'') |

| Standard | GB / DIN / ANSI / JIS / ISO |

| Length | 2 m / 3 m / 6 m / customized (10 ft / 19 ft / custom) |

| Packing | 50–100 pcs wrapped in plastic bags |

| Finish | Pre-galvanized, HDG, SS304, SS316, Aluminum, Powder Coated |

| No. | Size (mm) | Size (inch) | Thickness (mm) | Gauge | Type | Surface Finish |

|---|---|---|---|---|---|---|

| A | 41×21 | 1-5/8×13/16" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| B | 41×25 | 1-5/8×1" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| C | 41×41 | 1-5/8×1-5/8" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| D | 41×62 | 1-5/8×2-7/16" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| E | 41×82 | 1-5/8×3-1/4" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

ADVANTAGE

C Channel Steel is mainly employed for purlins and wall beams in steel structure, and can be used in lightweight roof trusses, building supports and steel building components. It can be also used for columns, beams and arms in machinery, instrumentation and light industrial production. Cold-formed from hot-rolled steel plates, the thin-walled C-shaped steel boasts light weight, strong cross-sectional performance and high strength. The same strength can be obtained as compared with the traditional channel steel, and the material can be saved by 30%.

With the development of national economy and the development trend of green building materials, the technology of producing steel in C shape has also been greatly developed. Is widely used in wall beams because of the benefits of:

1.Lightweight: It is made from hot-rolled steel and so is lighter, reducing load on structure and making construction easier than concrete.

2.Versatile and Stable: The exquisite internal design enables it to withstand larger vibrations and natural forces.

3.Productive: Additional materials and labor are saved during the welding process, precision is enhanced, and the weld is simple to disassemble and recycle.

PRODUCT INSPECTION

In order to guarantee the galvanized C channel plant's effective operation and provide the good performance, it is necessary to carry out the following testing and inspection regularly:

1.Power Production Efficiency: Check the PV system’s actual energy production against its theoretical production to ensure it is performing as expected.

2.Performance of modules: Photovoltaic components can be tested by measuring current, voltage, power and other parameters to observe performance and degradation.

3.System Stability: Test the stability and lifetime of core components including inverter, cable and other core components.

4.Environmental Evaluation: Investigate the influence on the environment during building and operating whether it is in line with the related regulations and rules.

PROJECT

Our company, C Channel Steel Suppliers, participated in the biggest solar work in South America with brackets and design solutions. Utilizing leading domestically developed technology, we delivered 15,000 tons of photovoltaic brackets that contributed to the growth of the photovoltaic industry in the area and to the improvement of life by local communities.

The project includes a 6 MW photovoltaic power plant and a 5 MW/2.5 h battery storage system, and it has a strong photoelectric conversion efficiency for producing approximately 1,200 kWh every year.

APPLICATION

-

Roof Installation:

Photovoltaic brackets can be installed on flat or sloped roofs. Selection depends on roof size, load capacity, and angle. Small and medium-sized structures are typically preferred for smaller solar installations due to ease of assembly and dismantling. -

Ground Installation:

For larger ground-mounted solar power stations, supports must account for terrain and slope to ensure stability and safety. Ground installations offer flexibility, easy maintenance, and convenient adjustments. -

Water Surface Installation:

Used on lakes, reservoirs, and other water bodies. Brackets must have strong corrosion and water resistance to withstand challenging aquatic environments.

C-Shaped Steel Purlins are essential in photovoltaic systems, providing support and secure mounting for solar panels while enhancing system efficiency and reliability.

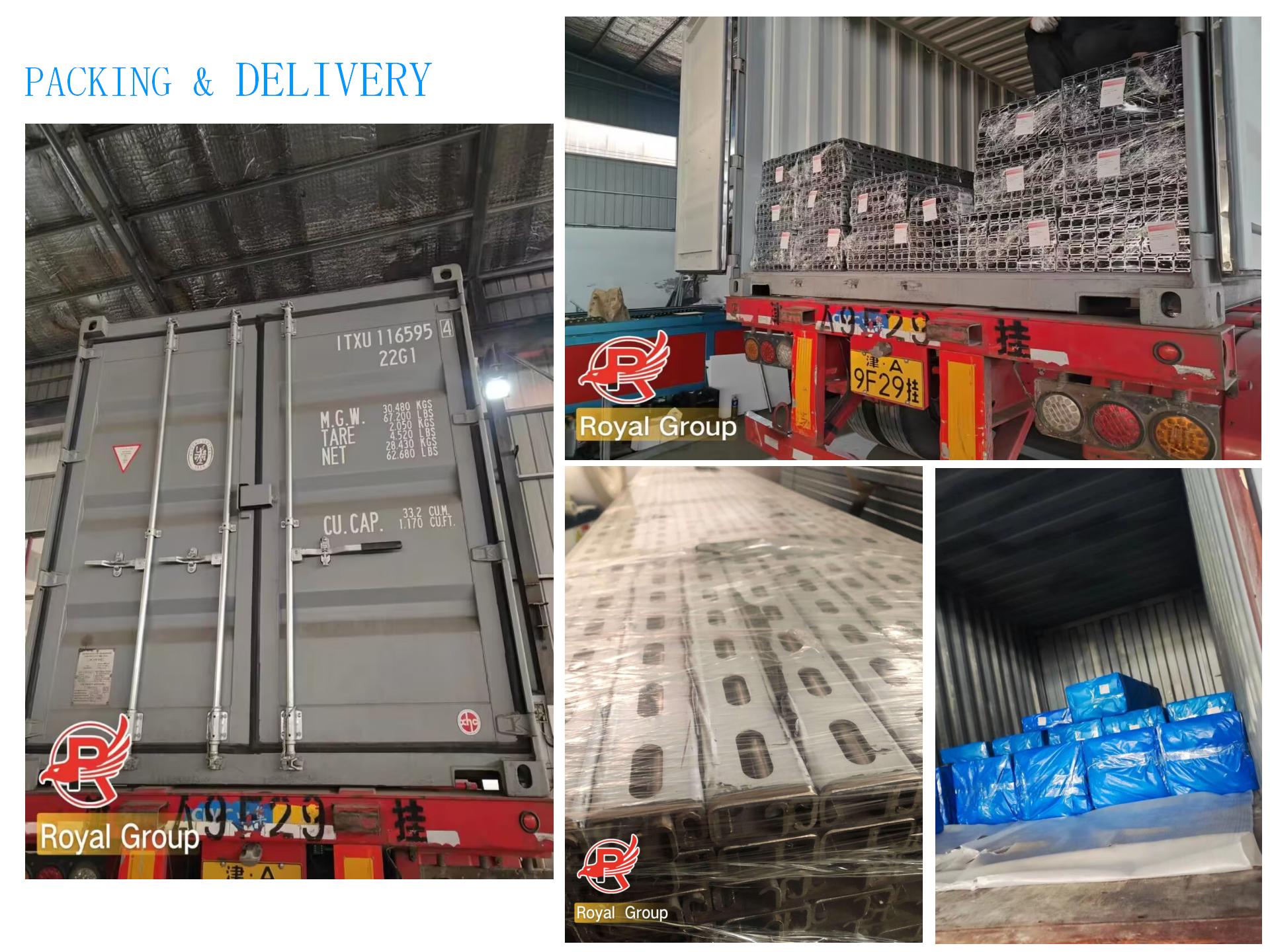

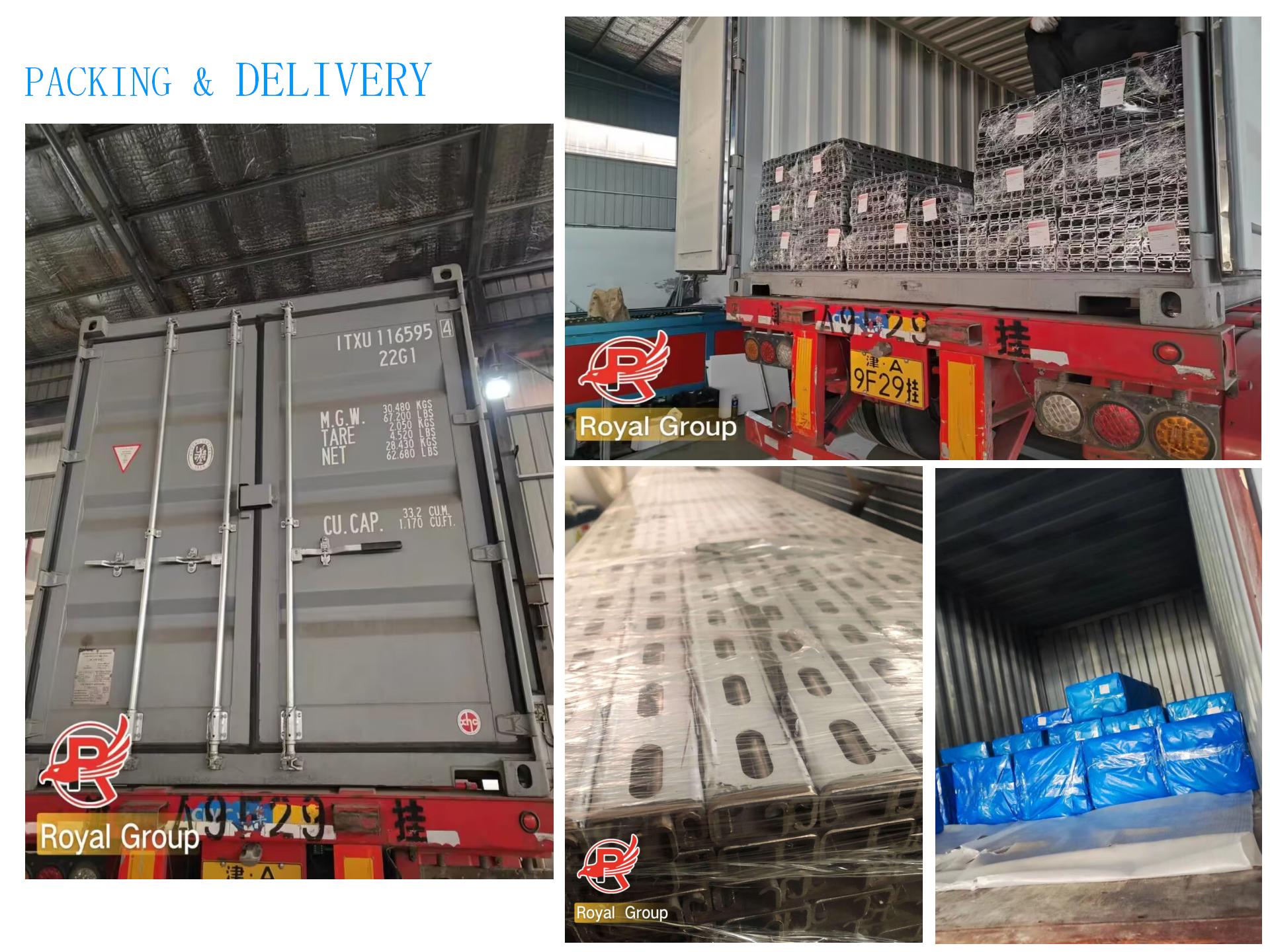

PACKAGING AND SHIPPING

1. Photovoltaic Module Packaging

Packaging protects the glass surfaces and bracket systems of photovoltaic modules, preventing damage during transport. Common packaging methods include:

-

Foam Boxes: Rigid foam boxes made with high-strength cardboard or wood, providing effective protection and easier handling.

-

Wooden Boxes: Stronger option for heavy items, though bulkier and less eco-friendly.

-

Pallets: Modules placed on corrugated cardboard pallets for stable, secure, and easy transport.

-

Plywood: Secures modules to prevent collisions or deformation during transit.

2. Transportation of Photovoltaic Modules

Modules can be transported by land, sea, or air, each with specific considerations:

-

Land Transport: Suitable for distances under 1,000 km within the same city or province. Ensure careful handling and use professional logistics providers.

-

Sea Transport: Ideal for long-distance, inter-provincial, or cross-border shipments. Pay attention to packaging, moisture protection, and work with reliable shipping companies.

-

Air Transport: Fast option for cross-border or long-distance delivery. Higher cost and proper protective measures are required.

COMPANY STRENGTH

Made in China – Quality Products & Reliable Service.

1.Scale Advantage: Large steel factory and steel supply chain for production, procurement and logistics.

2.Products Variety: We offer wide product categories including steel structure, rail, sheet pile, photovoltaic brackets, channel steel, silicon steel coils, etc to satisfy your different needs.

3.Stable Supply: Dependable manufacturing lines and supply chains for mass production.

4.Brand Influence: The strong regional market.

5.One-stop service: one stop service including customized design, manufacturing and logistics.

6.Great Value: Quality steels for reasonable price.

CUSTOMERS VISIT

Packing Options

1.Foam Box: High pressure strength foam box or wooden sturdy box for handling protection.

2.Wooden Box: Adequate protection for heavy products; space at a premium and not very eco-friendly.

3.Pallet: Modules resting on corrugated cardboard pallets for stability and handling.

4.Plywood: Attaches the modules so they don’t crash, squish or distort while in transit.

Shipping Methods

1.Land: Applicable for distance less than 1,000 Km; no crush, with professional logistice.

2.Sea: Suitable for long-distance, inter-province or international transport; pay attention to packaging, moisture protection and select dependable transport company.

3.Air: Quick cross-border delivery option; more expensive and needs to be handled properly.

COMPANY STRENGTH

CUSTOMERS VISIT

FAQ

1. Who are we?

We are based in Tianjin, China, established in 2012. We export to Southeast & South Asia (40%), Europe (20%), Africa (10%), North America (25%), and South America (5%). Our office has 51–100 employees.

2. How do we ensure quality?

Pre-production samples before mass production

Final inspection before shipment

3. What products do we offer?

Steel pipes, iron angles, iron beams, welded steel structures, and perforated steel products.

4. Why choose us?

High-quality products, competitive prices, fast delivery, excellent service, and compliance with multiple standards.

5. What services are available?

1.Delivery terms: FOB, CFR, CIF

2.Payment currency: USD, CNY

3.Payment methods: T/T, L/C

4.Languages: English, Chinese