Good Quality Hot Rolled Carbon U Beam C Channel Steel Black Iron Upn Channel

The UPE Beam (Universal section Parallel flanges European) is a hot rolled section made of steel that follows the European standards for quality in the industrial sector (EN 10025 series). It is a classic case of an open-section steel profile and has a U-shaped slot with the opining on one side.Usually in steel structure construction there are more usage in 3 inch channel and 4 inch channel. It is mainly used for carrying lateral loads or as a structural support which is widely used in building, machinery, warehousing

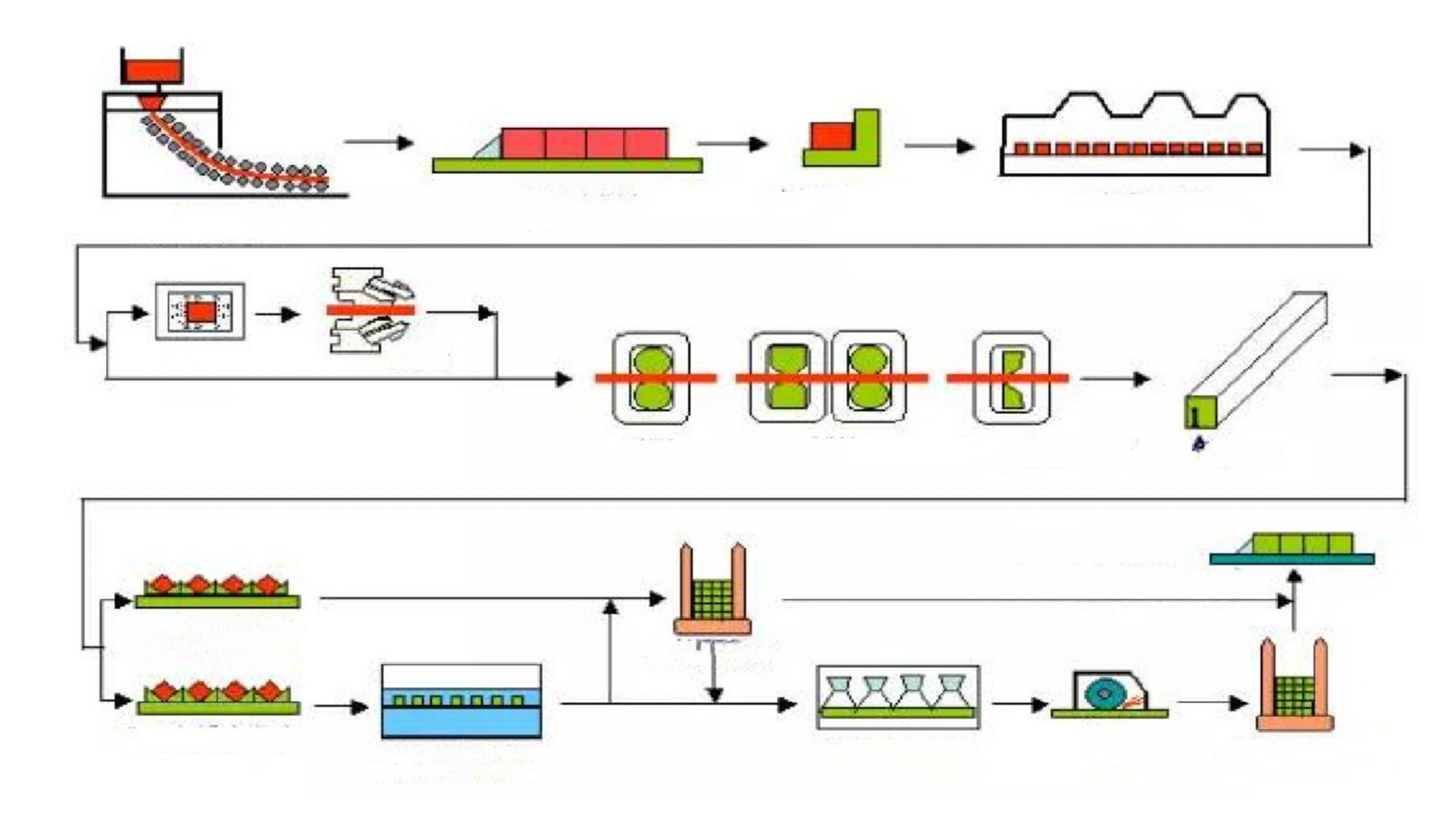

PRODUCT PRODUCTION PROCESS

1.Preparation of Raw Material - Iron ore, limestone, coal and oxygen are conditioned for orderly and productive operation.

2.Smelting Raw materials are smelted in a blast furnace to make molten iron. After deslagging, the iron is purified and modified in a converter or electric furnace to obtain the needed quality.

3.Rolling – The molten iron is cast into billets and rolled into channel steel with particular measurements. This dual-stage cooling allows for accurate temperature and quality control of the product.

4.Cutting – The channel steel is cut to your requirements by flame cutting, sawing or welding, and then inspected.

5.Testing – It is dimensionally tested, weighed and tested for mechanical and chemical properties. Passed product only taken out.

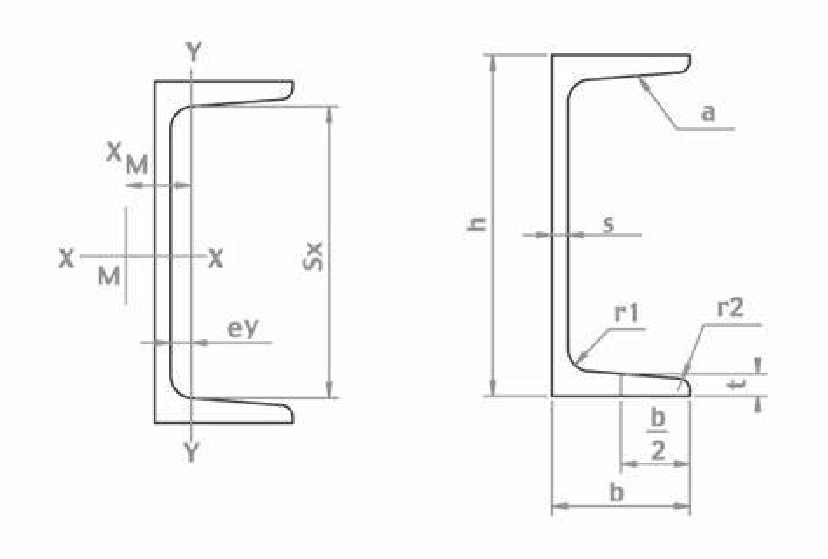

PRODUCT SIZE

| UPE UPE CHANNEL BAR STANDARD:GOST 8240-89 STEEL GRADE:EN10025 S235JR |

|||||

| SIZE | H(mm) | B(mm) | T1(mm) | T2(mm) | KG/M |

| UPE 80 | 80 | 40 | 4.5 | 7.4 | 7.05 |

| UPE 100 | 100 | 46 | 4.5 | 7.6 | 8.59 |

| UPE 120 | 120 | 52 | 4.8 | 7.8 | 10.4 |

| UPE 140 | 140 | 58 | 4.9 | 8.1 | 12.3 |

| UPE 160 | 160 | 64 | 5.0 | 8.4 | 14.2 |

| UPE 180 | 180 | 70 | 5.1 | 8.7 | 16.3 |

| UPE 200 | 200 | 76 | 5.2 | 9.0 | 13.4 |

Grade: S235JR,S275JR,S355J2,etc.

Size: UPN 80,UPN 100,UPN 120,UPN 140.UPN160,UPN 180,UPN 200,UPN 220,UPN 240,UPN 260.UPN 280.UPN 300.UPN320,UPN 350.UPN 380.UPN 400

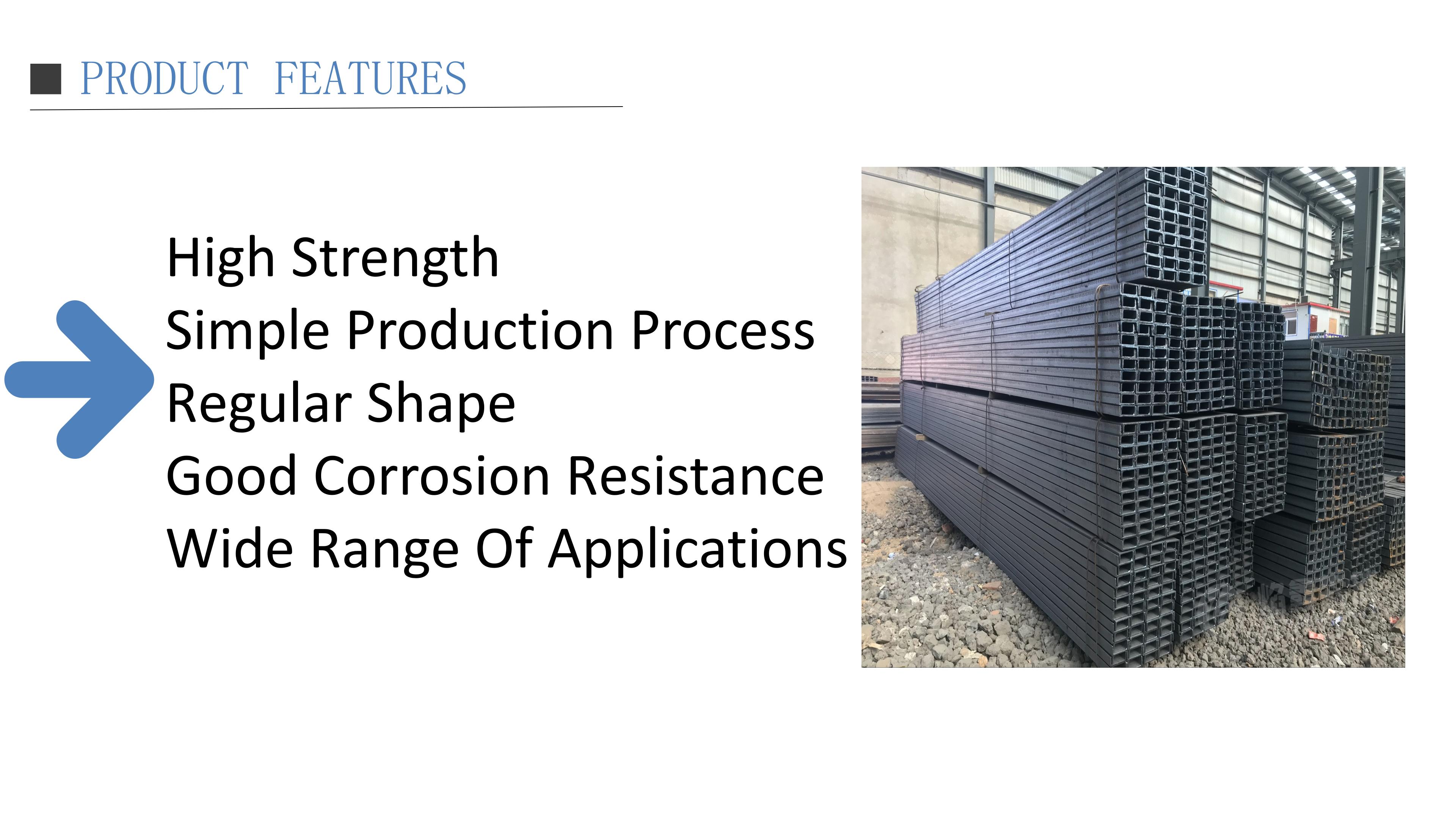

FEATURES

UPN H-beam or U-channels are a type of hot rolled steel beam with a U shape cross section. D-Section I-Beams are strong, stable, and versatile U-beam shapes that are perfect for supporting heavy loads in building, industrial and infrastructure work. The standardized dimensions enable them to be easily used in structural designs.

APPLICATION

UPN H-beams, or U-channels, are hot-rolled steel beams with a U-shaped cross-section. Strong, stable, and versatile, they are ideal for supporting heavy loads in buildings, bridges, industrial facilities, and machinery. Common applications include building frames, platforms, mezzanines, conveyor system structures, equipment racks, façades, and roofing. Their standardized dimensions make them easy to use in structural designs, making UPN beams essential in construction and engineering projects.

PACKAGING AND SHIPPING

1.Wrapping – Ends and middle are padded with canvas or plastic and strapped. Perfect for one-off pieces or small runs to stop scratching and damage.

2.Pallet Packing – Place the steel flat on a pallet, and strap or stretch wrap. Good for large quantities, and easier handling.

3.Sheet Metal Packing - Put steel in an iron case, seal it with sheet metal and strap it. Ideal for long storage & best protection.

COMPANY STRENGTH

Made in China — Top Quality, Reliable Service, Global Recognition

1.Scale Economy - The large production and supply network bring for low cost and efficient service.

2.Wide Product Range: Steel structure, rail, sheet pile, PV bracket, channel steel, silicon steel coil etc.

3.Reliable Supply: Production lines are stable which can ensure the delivery on time, no matter quantity is big or small.

4.Strong brand – established trust and presence in the market.

5.One-Stop Service - Customization, manufacturing, and logistics.

6.Competitive prices - good quality steel at reasonable prices.

7.Size:We offer 2x6 steel channel and support customization.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. How can I get a quotation?

Leave us a message, and we will respond promptly.

2. Will you deliver on time?

Yes. We guarantee high-quality products and timely delivery. Honesty is our core principle.

3. Can I get samples before ordering?

Yes. Samples are usually free and can be made according to your sample or technical drawings.

4. What are your payment terms?

Standard terms: 30% deposit, balance against B/L. We support EXW, FOB, CFR, and CIF.

5. Do you accept third-party inspection?

Yes, we do.

6. How can we trust your company?

We are an experienced steel supplier and verified gold supplier, headquartered in Tianjin. You are welcome to verify us by any means.