High Quality Q235B Carbon Steel China Galvanized C Channel Steel Column Factory China Suppliers

The UPE beam, which stands for "U"-shaped parallel flanged channel with an "N" or "I" cross-section, is a type of structural steel beam. It is commonly used in construction and industry to provide support and stability to various structures. UPN beams are designed to efficiently distribute weight, enabling them to carry heavy loads and resist bending and torsional forces. These beams are available in a variety of sizes to meet diverse structural needs. Due to their high strength and versatility, UPN beams are widely used in buildings, bridges, and other infrastructure projects.

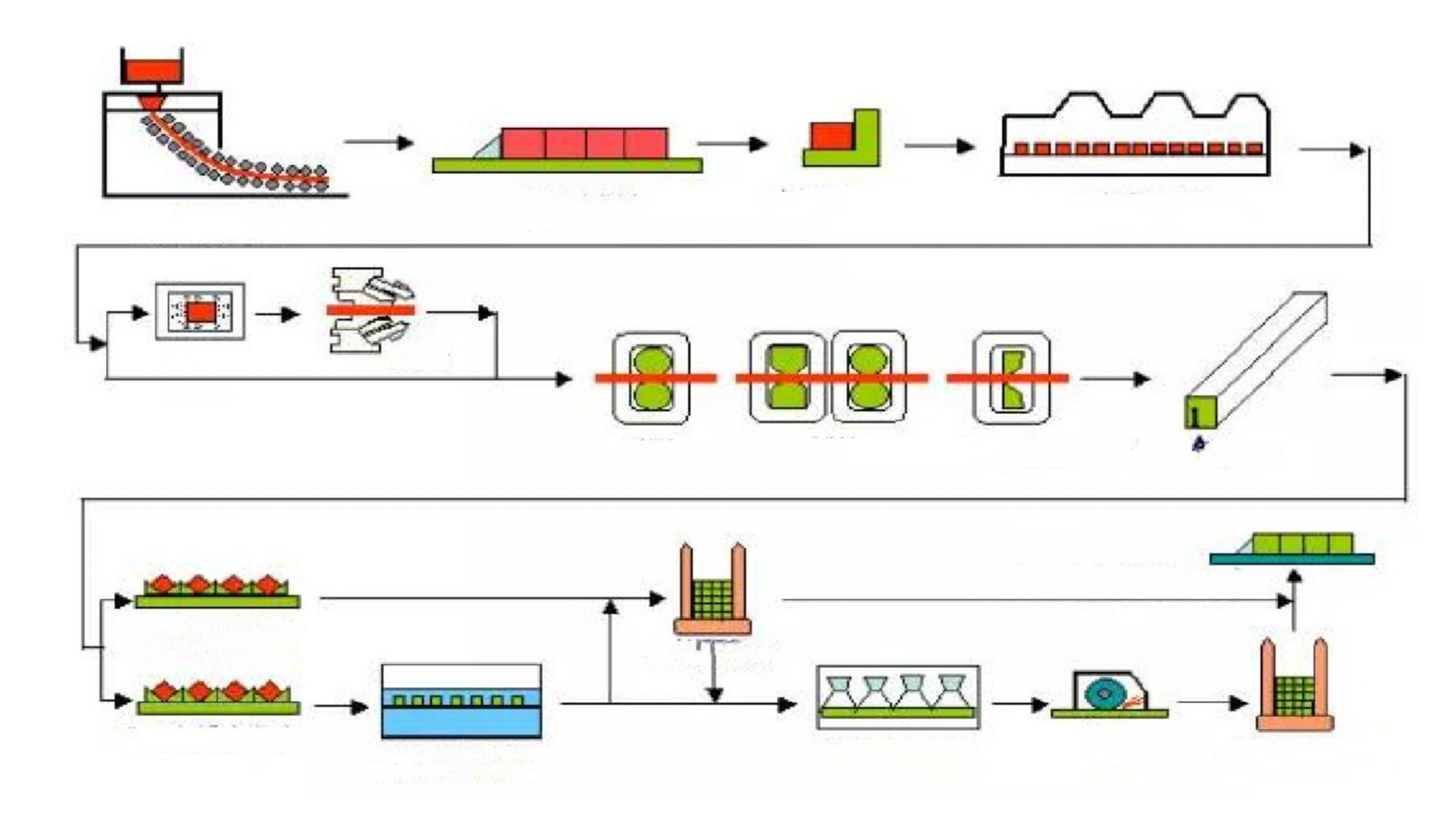

PRODUCT PRODUCTION PROCESS

Universal Beam production process

1. Raw Material Preparation

The main raw materials for channel steel are iron ore, limestone, coal, and oxygen. These raw materials must be prepared before production to ensure a continuous and efficient production process.

2. Smelting

The raw materials are smelted into molten iron in a blast furnace. After deslagging, the molten iron is transferred to a converter or electric furnace for refining and mixing. By controlling parameters such as pouring volume and oxygen flow, the composition of the molten iron is adjusted to the appropriate ratio, preparing it for the next step of rolling.

3. Rolling

After smelting, the molten iron flows downward in a continuous casting machine, forming a hot billet. The billet undergoes a series of rolling steps in the rolling mill, ultimately becoming a channel steel of a specified size. During the rolling process, water is continuously added and cooled to control the steel temperature and ensure product quality.

4. Cutting

The produced channel steel needs to be cut and segmented according to customer specifications. Various cutting methods are used, such as welding, sawing, and flame cutting, with flame cutting being the most commonly used. After cutting, the channel steel undergoes further inspection to ensure that each section meets quality requirements.

5. Testing

The final step involves subjecting the channel steel products to various tests, including dimensional, weight, mechanical properties, and chemical composition. Only those that pass these tests are allowed to enter the market.

Overall, the channel steel production process is a complex one, requiring precise control at multiple stages to achieve ideal product quality and performance. With technological advancements and process improvements, the channel steel production process will continue to be optimized to provide customers with even higher-quality products and services.

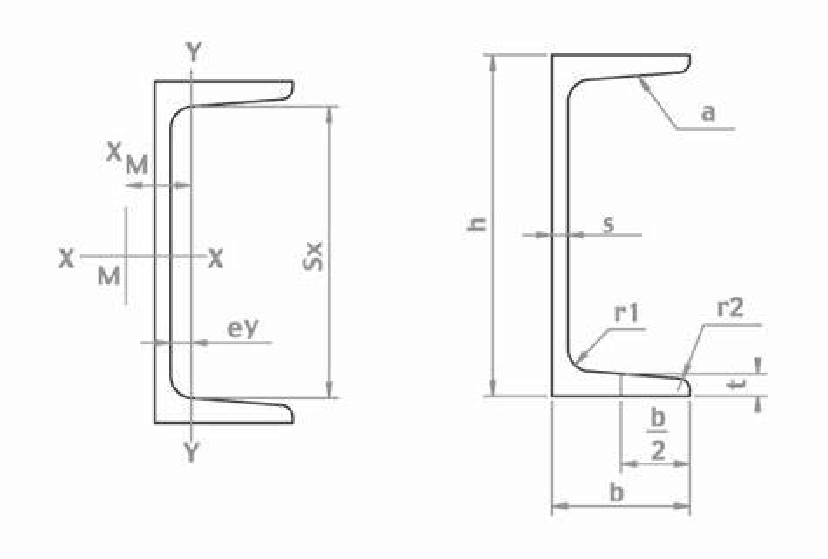

PRODUCT SIZE

| UPN EUROPEAN STANDARD CHANNEL BAR DIMENSION:DIN 1026-1:2000 STEEL GRADE:EN10025 S235JR |

|||||

| SIZE | H(mm) | B(mm) | T1(mm) | T2(mm) | KG/M |

| UPN 140 | 140 | 60 | 7.0 | 10.0 | 16.00 |

| UPD 160 | 160 | 65 | 7.5 | 10.5 | 18.80 |

| UPN 180 | 180 | 70 | 8.0 | 11.0 | 22.0 |

| UPN 200 | 200 | 75 | 8.5 | 11.5 | 25.3 |

Grade:

S235JR,S275JR,S355J2,etc.

Size:UPN 80,UPN 100,UPN 120,UPN 140.UPN160,

UPN 180,UPN 200,UPN 220,UPN240,UPN 260.

UPN 280.UPN 300.UPN320,

UPN 350.UPN 380.UPN 400

Standard:EN 10025-2/EN 10025-3

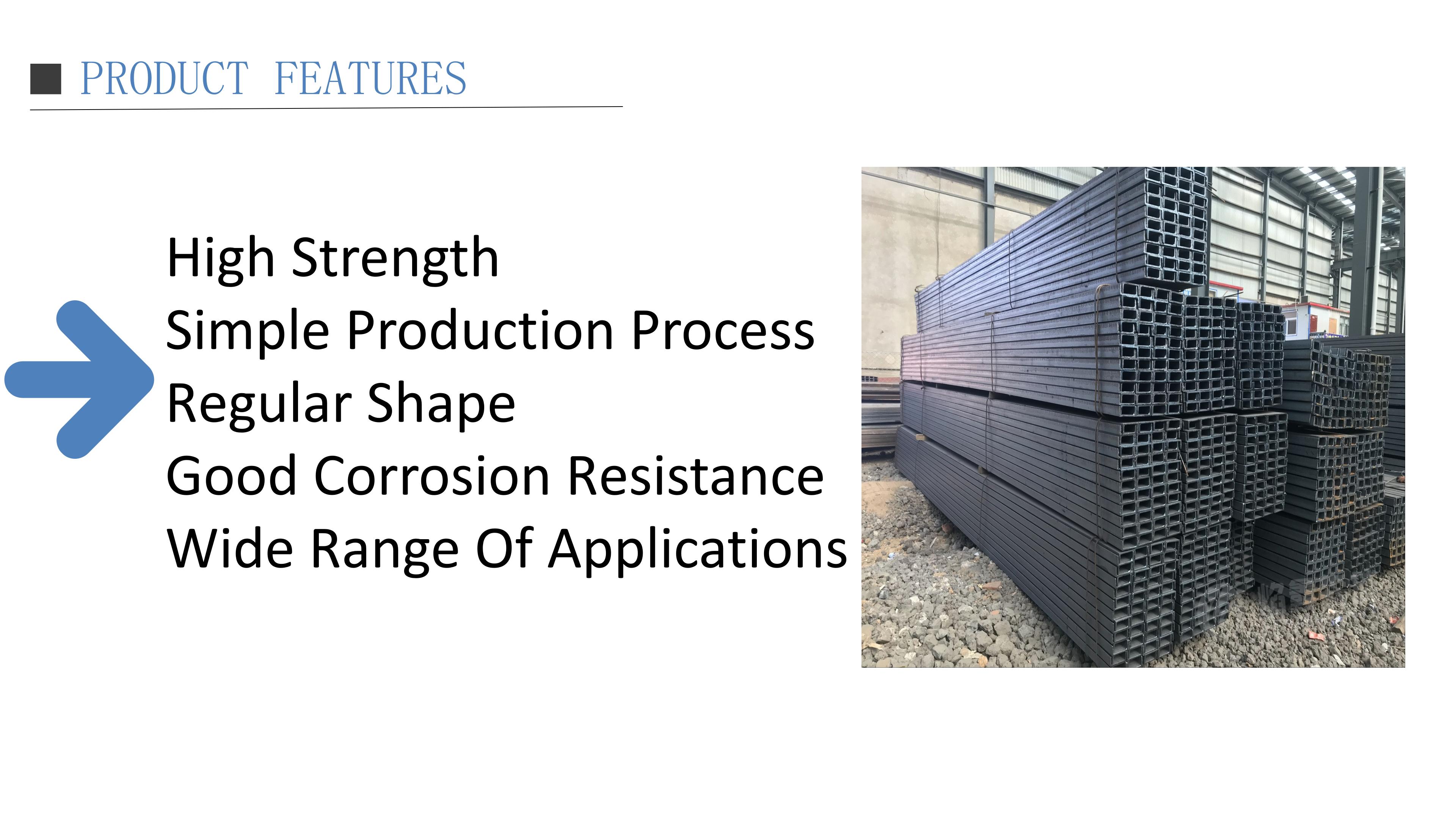

FEATURES

UPN H beam, also known as U-channel steel, UPN beams are a type of structural steel beam with a typical U-shaped cross-section. They are typically made from hot-rolled steel and are available in a variety of sizes and specifications to meet specific construction requirements. UPN beams are highly regarded for their strength, stability, and versatility, making them suitable for a wide range of applications. Their standardized dimensions and consistent cross-sectional characteristics make them easy to use in structural design, and they are commonly used to provide support and carry heavy loads in construction and industrial settings. The properties of UPN beams make them a popular choice for a variety of construction and infrastructure projects.

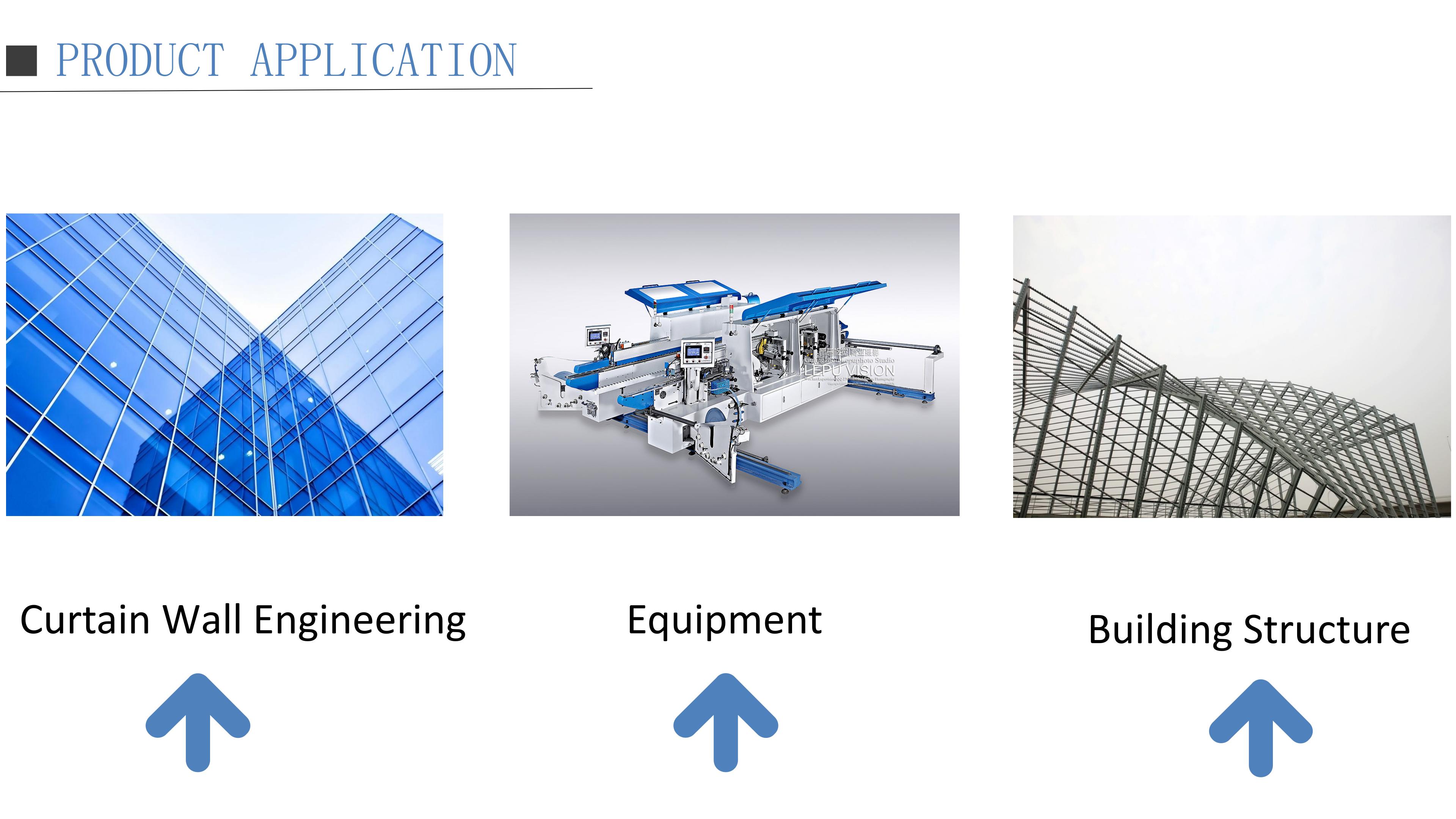

APPLICATION

UPN beams, which are widely used in construction, have numerous applications. They are frequently employed in building frames, as well as in support structures for bridges, industrial facilities, and various types of machinery. Additionally, UPN beams are commonly utilized in the construction of platforms, mezzanines, and other elevated structures, as well as in the creation of frameworks for conveyor systems and equipment supports. These versatile beams are also essential in the development of building façades and roofing systems. Overall, UPN beams are vital components in a wide range of construction and engineering applications.

PACKAGING AND SHIPPING

1. Wrapping: Wrap the upper and lower ends and the middle of the channel steel with canvas, plastic sheet and other materials, and achieve packaging through bundling. This packaging method is suitable for a single piece or a small amount of channel steel to prevent scratches, damage and other situations.

2. Pallet packaging: Place the channel steel flat on the pallet, and fix it with strapping tape or plastic film, which can reduce the workload of transportation and facilitate handling. This packaging method is suitable for the packaging of large quantities of channel steel.

3. Iron packaging: Put the channel steel into the iron box, and then seal it with iron, and fix it with a binding tape or plastic film. This way can better protect the channel steel and is suitable for long-term storage of the channel steel.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.