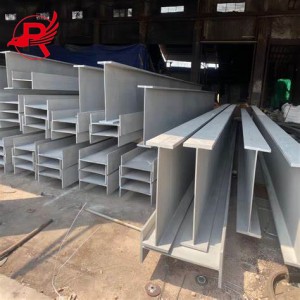

High Quality Steel Galvanized C Shape Channel Beam Steel Channel bar C Type Channel System

Each pole is mounted on an independent support structure consisting of a horizontal axis and vertical support beams. The horizontal axis is typically oriented north-south. By controlling the rotation of the horizontal axis, the tilt angle of the support beam can be adjusted accordingly. A tracking angle range of ±60° is common, but products with a tracking angle range of ±45° are also available. This ensures that the photovoltaic panels are always facing the sun and automatically adjust according to the solar altitude at different times of day and seasons.

China Galvanized Steel C Channel Suppliers would be a reliable supplier if you have demand for zinc coated c channel steel.

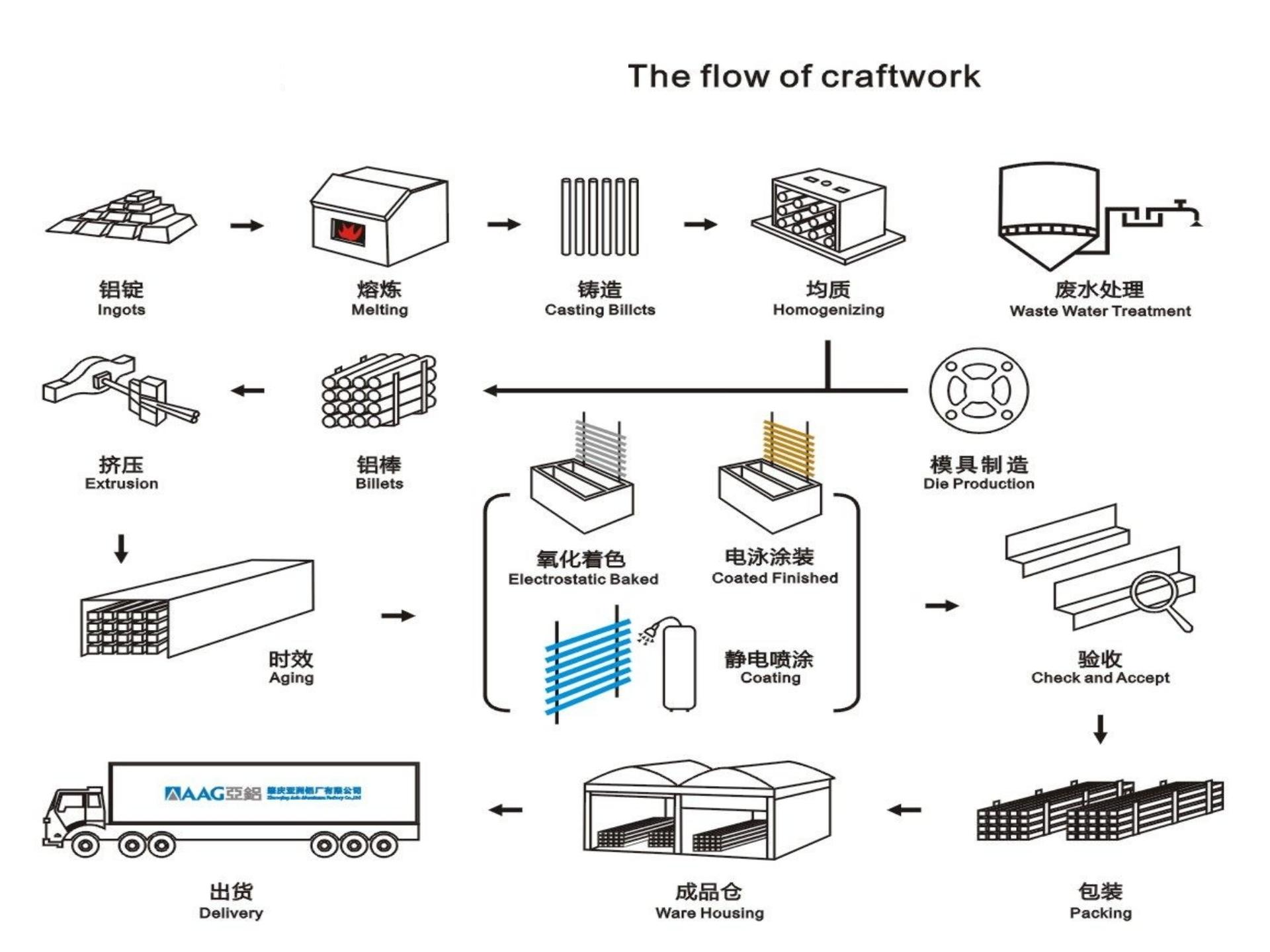

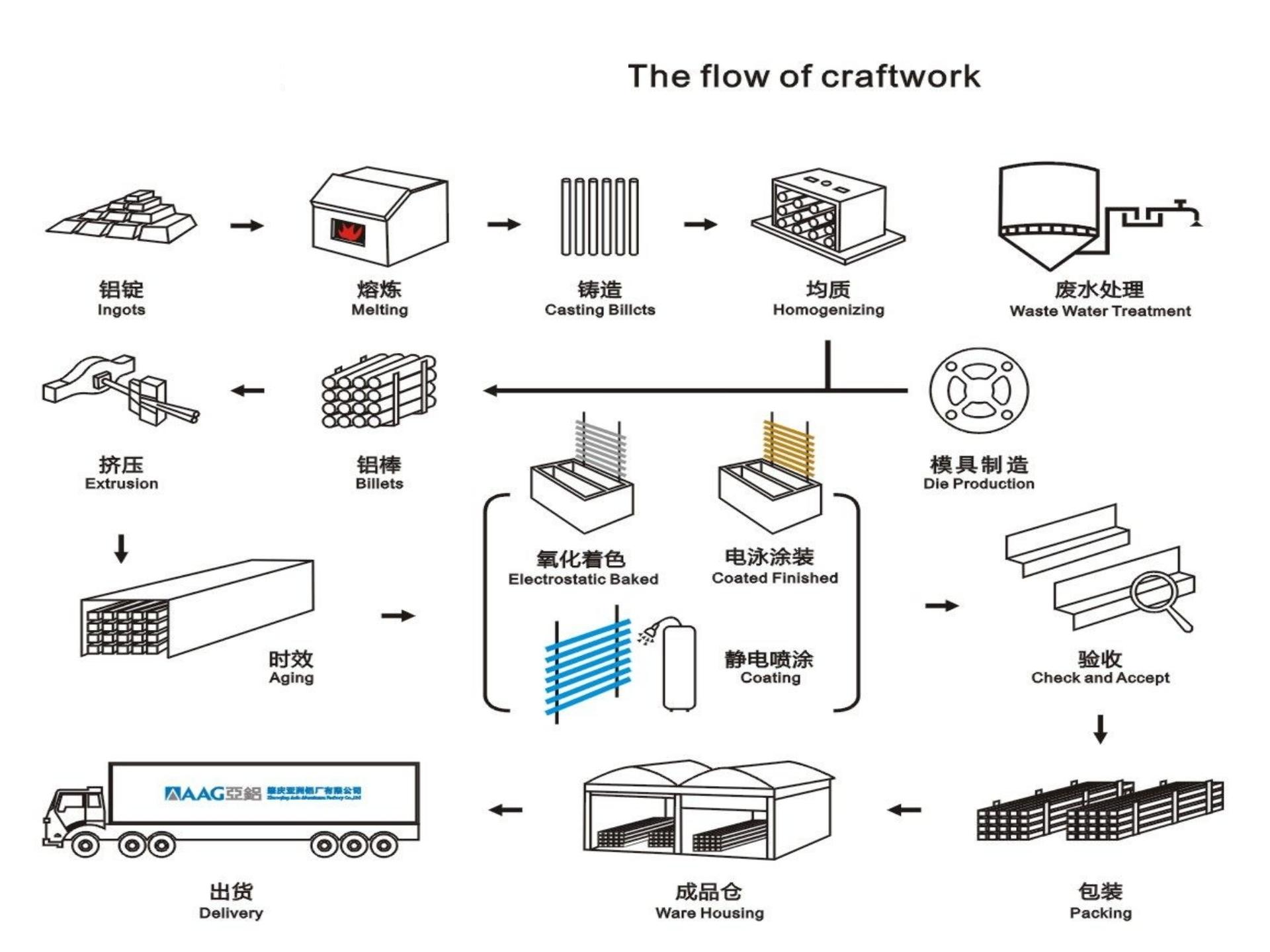

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

For use to support conduits, fixtures and ventilation systems from beams and other strutctural systems.

|

Product Name

|

Made in China Hot Dip Galvanized Steel Slotted Strut C Channel ( C Channel, Unistrut, Uni Strut Channel)

|

|

Material

|

Q195/Q235/SS304/SS316/Aluminum

|

|

Thickness

|

1.5mm/2.0mm/2.5mm

|

|

Type

|

41*21,/41*41 /41*62/41*82mm with slotted or plain

|

|

Length

|

3m/3.048m/6m

|

|

Finished

|

Pre-galvanized/HDG/power coated

|

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

In today's era, it is our goal to follow the path of sustainable development of strut c channel order to carry forward photovoltaic brackets, the application of various new forces has brought us hope. Solar energy is a clean energy source. To use solar energy, you need to install a bracket. The quality of the Xinxiang photovoltaic bracket will also affect the overall performance. At present, the photovoltaic bracket systems commonly used in my country mainly include concrete brackets, hot-dip galvanized photovoltaic brackets and aluminum alloy brackets in terms of materials.

1. Concrete brackets are primarily used for large-scale photovoltaic power plants. Due to their complex structure, they can only be installed outdoors in areas with good foundations. However, they are highly stable and can support large modules.

2. Hot-dip galvanized photovoltaic brackets offer stable performance, mature production technology, high load-bearing capacity, easy installation, excellent corrosion resistance, and an attractive appearance. Their unique connection design allows for quick and easy installation with simple and universal installation tools. They utilize structurally corrosion-resistant steel and stainless steel components, resulting in a service life of over 20 years.

3. Aluminum alloy brackets are commonly used for solar applications on residential rooftops. Aluminum alloy is corrosion-resistant, lightweight, aesthetically pleasing, and durable, but its low load-bearing capacity makes it unsuitable for solar power plant projects.

PRODUCT INSPECTION

Structural bearing capacity testing: Including testing the bearing capacity of steel c channel profile Manufacturers and other structural components to ensure that they can withstand the weight of photovoltaic equipment and other environmental factors (such as wind, snow, etc.).

Connection Quality Test: This test examines the connection quality between the PV system and structural components such as the bracket and base, including the tightness and stability of bolts, welds, and other connection methods.

Wind Resistance Test: This test checks whether the PV system can maintain stability under specified wind speeds based on local wind load conditions.

Seismic Test: This test examines the quality of the materials used in the PV system, including the mechanical properties and chemical composition of materials such as steel and aluminum alloy.

Corrosion Resistance Test: This test examines the corrosion resistance of the PV system and assesses its durability and corrosion resistance during use.

Electrical Safety Test: This test examines the PV system's electrical system, including the insulation performance of wires and cables and the grounding of electrical equipment, to ensure electrical safety during use.

PROJECT

Our company Strut Channel Frame has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

Solar Strut C Channel Supplier power generation brackets and accessories are important components of solar photovoltaic power generation systems. Solar photovoltaic bracket accessories play a decisive role in the entire solar photovoltaic power generation system. The quality of solar photovoltaic bracket accessories seriously affects the power generation efficiency of the entire power generation system. Accurate selection and reasonable installation of solar photovoltaic mounting accessories system is very necessary.

PRODUCT PRODUCTION PROCESS

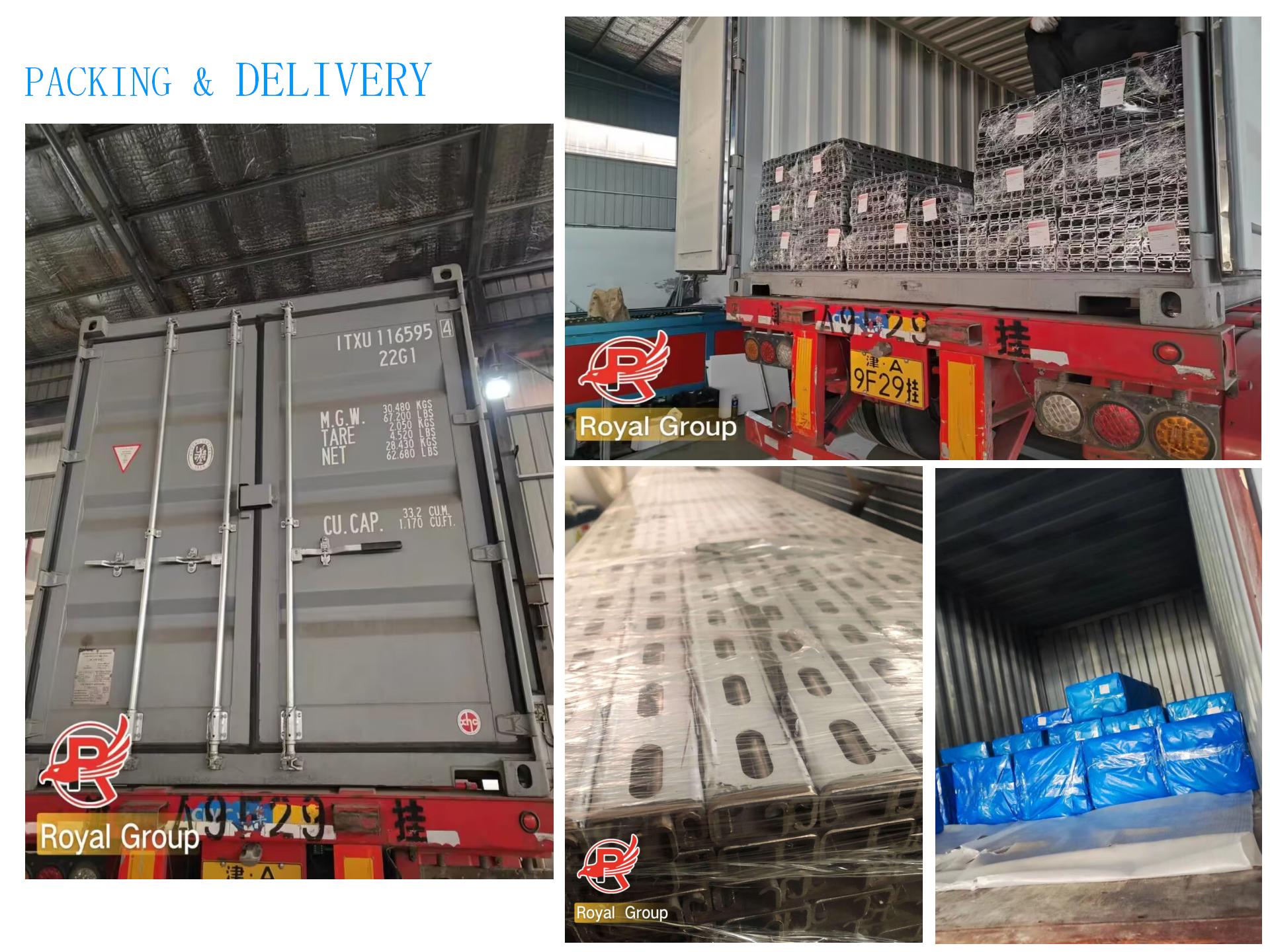

1. PV Module Packaging

The packaging of PV modules is primarily intended to protect the glass surface and mounting system, preventing collisions and damage during transportation. Therefore, the following packaging materials are commonly used for PV modules:

1. Foam Boxes: Rigid foam boxes are used for packaging. Made from high-strength cardboard or wood, foam boxes effectively protect the PV modules and facilitate transportation and handling.

2. Wooden Boxes: Considering the potential for collisions and crushing of heavy objects during transportation, ordinary wooden boxes offer greater sturdiness. However, this packaging method takes up considerable space and is environmentally friendly.

3. Pallets: Specialized pallets are used for packaging, placed on corrugated cardboard, to stably support the PV panels, ensuring they are secure and easy to transport.

4. Plywood: Plywood is used to secure the PV modules, protecting them from collisions and crushing during transportation, thereby preventing damage or deformation.

2. Transporting PV Modules

There are three main methods of transporting PV modules: land, sea, and air. Each method has its own unique characteristics. 1. Land transport: Suitable for transport within the same city or province, with single trips not exceeding 1,000 kilometers. General transport and logistics companies can deliver PV panels to their destination via land transport. During transportation, be careful to avoid collisions and crushing, and choose a professional transport company if possible.

2. Ocean transport: Suitable for interprovincial, cross-border, and long-distance transport. Ensure packaging, protective treatment, and moisture-proofing are ensured, and partner with large logistics companies or professional freight companies if possible.

3. Air transport: Suitable for cross-border or long-distance transport, significantly reducing transportation time. However, air transport costs are higher, and appropriate protective measures must be taken.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.