Hot Dip Galvanized Round Steel Pipe / GI Pipe Pre Galvanized Steel Pipe Galvanized Tube

Product Detail

Specifically, it is mainly used in the following fields:

1. Construction field: such as building frames, steel structures, stair railings, etc.;

2. Transportation field: such as road guardrails, ship structures, automobile chassis, etc.;

3. Metallurgical field: such as pipeline systems for transporting ore, coal, slag, etc.

Product Of Advantages

As a steel pipe product with strong technical content, galvanized pipe has a wide range of uses and many advantages. It is an indispensable pipeline system material in construction, transportation, metallurgy and other fields. In future market demand, galvanized pipes will have wider application prospects.

Main Application

Application

1. Anti-corrosion performance: The surface of galvanized pipe is plated with zinc layer, which has strong anti-corrosion performance and will not rust after long-term use.

2. Durability: Due to the galvanizing on the surface, galvanized pipes have high durability and have a relatively long service life.

3. Aesthetics: The surface of galvanized pipe is smooth and bright, and can be used directly without surface treatment.

4. Plasticity: Galvanized pipes have good plasticity during the manufacturing process, and pipes of various shapes can be manufactured as needed.

5. Weldability: Galvanized pipes are easy to weld during the manufacturing process, thus facilitating construction.

Parameters

|

Product name |

Galvanized Pipe |

| Grade | Q235B, SS400, ST37, SS41, A36 etc |

| Length | Standard 6m and 12m or as customer requirement |

| Width | 600mm-1500mm, according to customer's requirement |

| Technical | Hot Dipped Galvanized pipe |

| Zinc Coating | 30-275g/m2 |

| Application | Wide used in various building structures, bridges, vehicles, bracker, machinery etc. |

Details

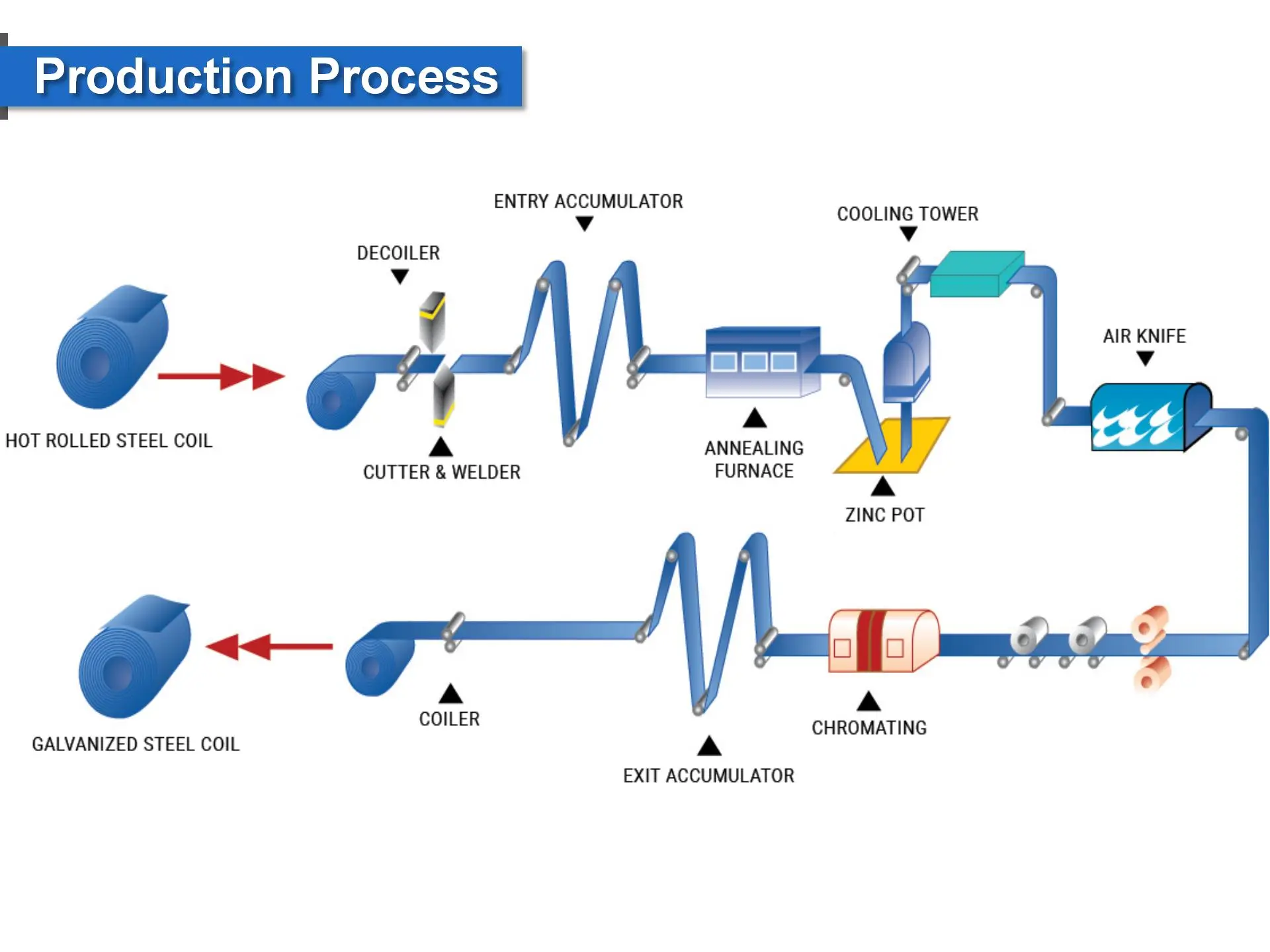

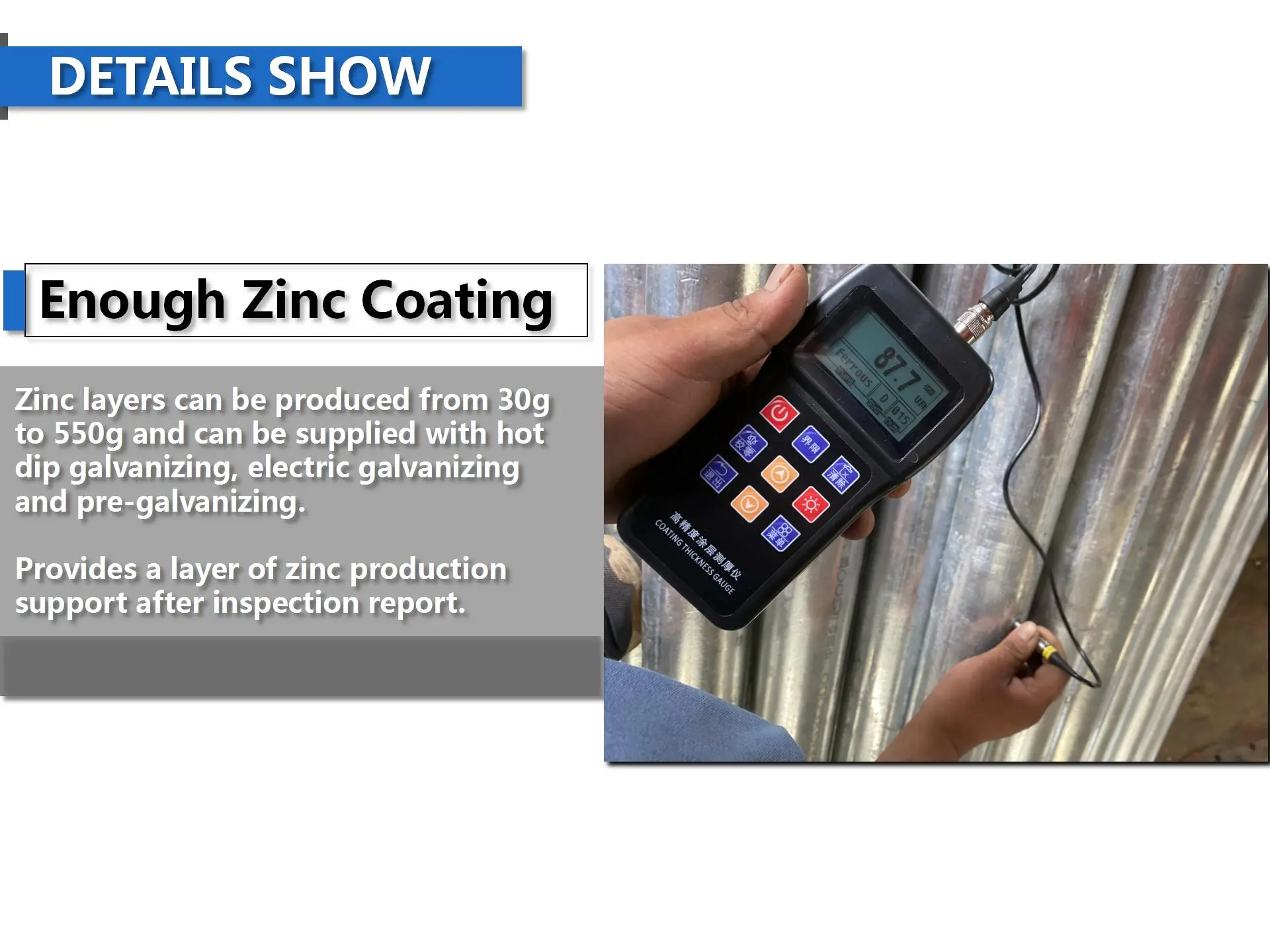

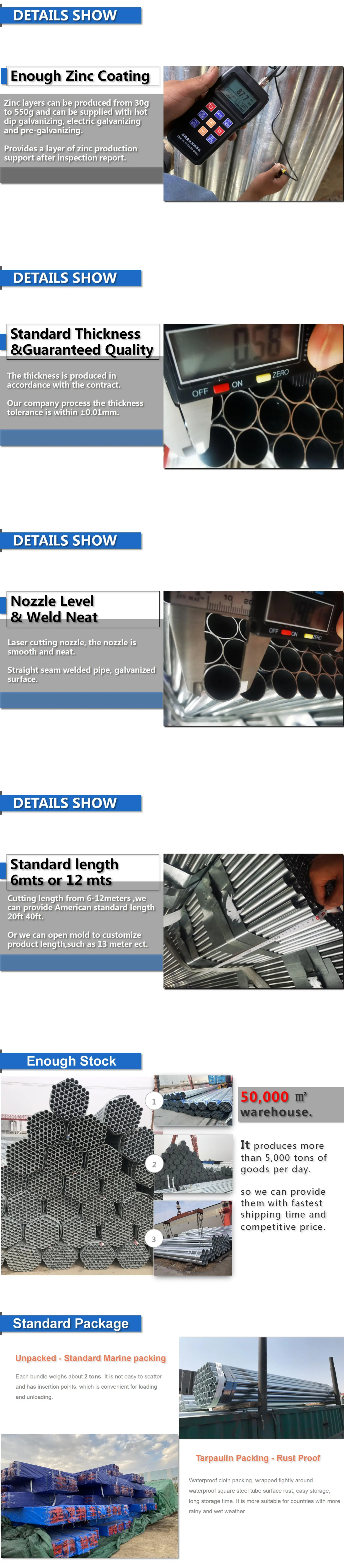

Zinc layers can be produced from 30gto 550g and can be supplied with hot dip galvanizing, electric galvanizingand pre-galvanizing Provides a layer of zinc productionsupport after inspection report.The thickness is produced inaccordance with the contract.Our company process the thicknesstolerance is within ±0.01mm.Zinc layers can be produced from 30gto 550g and can be supplied with hotdip galvanizing, electric galvanizingand galvanizing Provides a layer of zinc productionsupport after inspection report.The thickness is produced inaccordance with the contract.Our company process the thicknesstolerance is within ±0.01mm.Laser cutting nozzle, the nozzle issmooth and neat.Straight seam welded pipe, galvanizedsurface.Cutting length from 6-12meters ,wecan provide American standard length20ft 40ft.Or we can open mold to customizeproduct length,such as 13 meter ect.50.000m warehouse.It produces morethan 5,000 tons ofgoods per day.so we can providethem with fastestshipping time andcompetitive price.

Galvanized pipe is a common building material with a wide range of uses. During transportation, due to the influence of environmental factors, steel pipes are prone to rust, deformation or damage. Therefore, the packaging and transportation of galvanized pipes are very important. This article will introduce the packaging methods of galvanized pipes during transportation.

1. Packaging requirements

(1). The surface of the steel pipe should be clean and dry, and must not have grease, dust or other debris.

(2). The steel pipe must be packaged with double-layer plastic-coated paper, with the outer layer covered with plastic cloth with a thickness of not less than 0.5mm and the inner layer covered with transparent polyethylene plastic film with a thickness of not less than 0.02mm.

(3). The steel pipe must be marked after packaging. The marking content should include the model, specification, batch number and production date of the steel pipe.

(4). The steel pipe should be classified and packaged according to different categories such as specification, size, and length to facilitate loading, unloading and storage.

2. Packaging method

(1). Before packaging the galvanized pipe, the surface of the pipe should be cleaned to ensure that the surface is clean and dry to avoid corrosion and other problems during transportation.

(2) When packaging galvanized pipes, attention should be paid to the protection of the steel pipes. Red cork plywood should be used to reinforce both ends of the steel pipes to prevent deformation and damage during packaging and transportation.

(3) The packaging materials of galvanized pipes must be moisture-proof, waterproof, and rust-proof to ensure that the steel pipes are not damp or rusted during transportation.

(4) After packaging, galvanized pipes should be protected from moisture and sun exposure and should not be exposed to sunlight or humid environments for a long time.

3. Precautions

(1) When packaging galvanized pipes, attention should be paid to the standardization of size and length to avoid waste and loss caused by size mismatch.

(2) After packaging, galvanized pipes should be marked and classified in time for management and storage.

(3) When packaging galvanized pipes, attention should be paid to the height and stability of the stacking of goods to avoid damage to the goods caused by tilting or stacking too high. The above is the packaging method of galvanized pipes during transportation, including packaging requirements, packaging methods and precautions. When packaging and transporting, you must strictly follow the regulations to effectively protect the steel pipes and ensure that the goods arrive safely at their destination.

FAQ

Q: Are u a manufacturer?

A: Yes, we are a manufacturer. We have our own factory located in Tianjin City, China.

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.