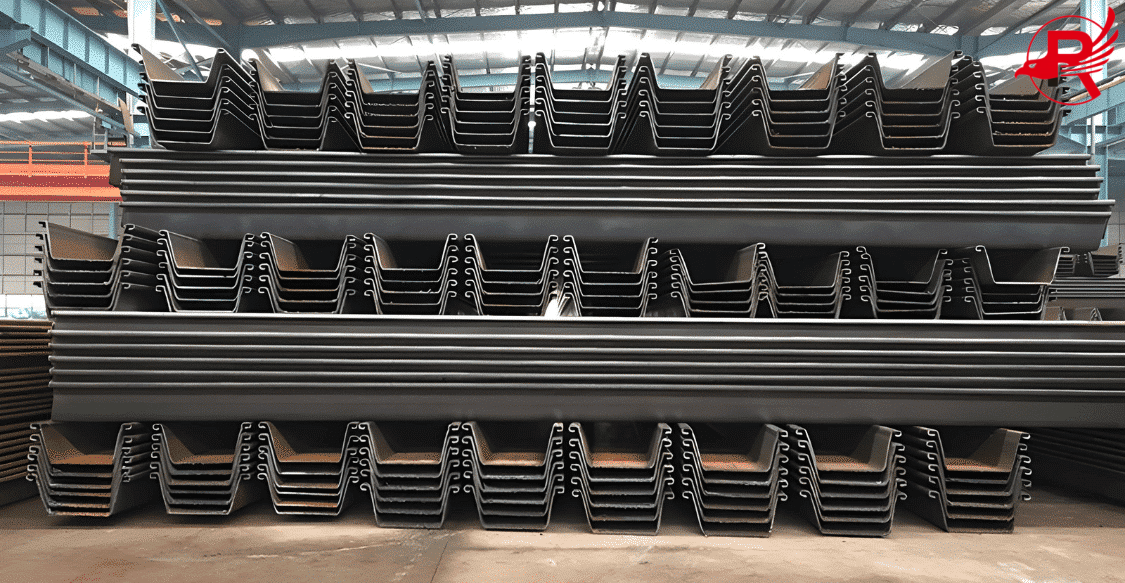

Hot Rolled ASTM A328 Grade 50/55/60/65 ASTM A588 Grade A JIS A5528 SY295/SY390/SY490 6m-18m U-shaped Steel Sheet Pile

| Steel Grade | ASTM A328 Grade 50/55/60/65 ,ASTM A328 Grade 65,ASTM A588 Grade A,JIS A5528 SY295/SY390/SY490 |

| Standard | JIS A5528,ASTM A328,ASTM A588 |

| Delivery time | 10~20 Days |

| Certificates | ISO9001,ISO14001,ISO18001,CE FPC |

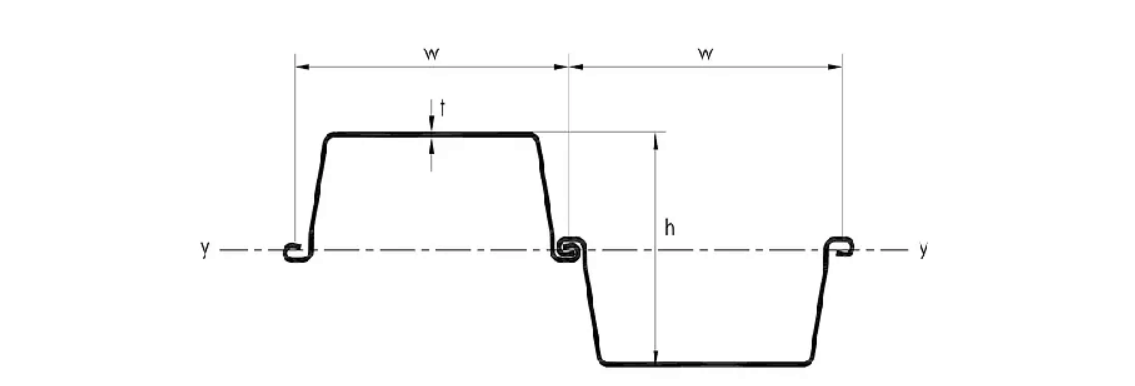

| Width | 400mm/15.75in、600mm/23.62in、750mm/29.53in |

| Height | 100mm/3.94in–225mm/8.86in |

| Thickness | 9.4mm/0.37in–23.5mm/0.92in |

| Length | 6m-24m,9m,12m,15m,18m and custom |

| Type | U-shape steel sheet pile |

| Processing Service | Punching, Cutting |

| Material composition | C≤0.22%, Mn≤1.60%, P≤0.035%, S≤0.035%, conforming to both JIS A5528 and ASTM A328 standards. |

| Mechanical properties | Yield strength ≥ 390 MPa/56.5 ksi; Tensile strength ≥ 540 MPa/78.3 ksi; Elongation ≥ 18% |

| Technique | Hot Rolled |

| Dimensions | PU400x100 PU400x125 PU400x150 PU400x170 PU500x200 PU500x225 PU600x130 PU600x180 PU600x210 |

| Interlock types | Larssen locks,cold rolled interlock,hot rolled interlock |

| Certification | JIS A5528, ASTM A328, CE, SGS certification badges |

| Structural Standards | The Americas market is associated with the AISC Design Standard, while the Southeast Asian market is associated with the JIS Basic Engineering Design Standard. |

| Application | Port & wharf construction, bridges, deep foundation pits, water projects, and emergency rescue |

| JIS A5528 Model | ASTM A328 Corresponding Model | Effective Width (mm) | Effective Width (in) | Effective Height (mm) | Effective Height (in) | Web Thickness (mm) |

| U400×100(ASSZ-2) | ASTM A328 Type 2 | 400 | 15.75 | 100 | 3.94 | 10.5 |

| U400×125(ASSZ-3) | ASTM A328 Type 3 | 400 | 15.75 | 125 | 4.92 | 13 |

| U400×170(ASSZ-4) | ASTM A328 Type 4 | 400 | 15.75 | 170 | 6.69 | 15.5 |

| U600×210(ASSZ-4W) | ASTM A328 Type 6 | 600 | 23.62 | 210 | 8.27 | 18 |

| U600×205(Customized) | ASTM A328 Type 6A | 600 | 23.62 | 205 | 8.07 | 10.9 |

| U750×225(ASSZ-6L) | ASTM A328 Type 8 | 750 | 29.53 | 225 | 8.86 | 14.6 |

| Web Thickness (in) | Unit Weight (kg/m) | Unit Weight (lb/ft) | Material (Dual Standard Compatible) | Yield Strength (MPa) | Tensile Strength (MPa) | Applicable Scenarios for the Americas Market | Applicable Scenarios for the Southeast Asian Market |

| 0.41 | 48 | 32.1 | SY390 / Grade 50 | 390 | 540 | North American small-scale municipal pipe networks and agricultural irrigation systems | Indonesia/Philippines Farmland Irrigation |

| 0.51 | 60 | 40.2 | SY390 / Grade 50 | 390 | 540 | American Midwestern building foundation support | Bangkok Urban Drainage Project |

| 0.61 | 76.1 | 51 | SY390 / Grade 55 | 390 | 540 | Gulf Coast flood control dikes | Singapore Land Reclamation Project (Small Section) |

| 0.71 | 106.2 | 71.1 | SY390 / Grade 60 | 390 | 540 | Houston Port seepage prevention, Texas shale oil dikes | Jakarta Deep-Sea Port Support |

| 0.43 | 76.4 | 51.2 | SY390 / Grade 55 | 390 | 540 | California river management | Ho Chi Minh City Coastal Industrial Zone Protection |

| 0.57 | 116.4 | 77.9 | SY390 / Grade 60 | 390 | 540 | Vancouver Port deep foundation pits, Canada | Malaysia Large-Scale Land Reclamation Project |

Americas: Hot-dip galvanized (compliant with ASTM A123, zinc layer ≥85μm) + optional 3PE coating, labeled "Environmentally friendly RoHS compliant".

Southeast Asia: Hot-dip galvanized (zinc layer ≥100μm) + epoxy coal tar coating, emphasizing "no rust after 5000 hours of salt spray test, suitable for tropical marine climate".

Design: Yin-yang interlocking design, permeability coefficient ≤1×10⁻⁷cm/s

Americas Compliant with: ASTM D5887 seepage prevention standard in the Americas

Southeast Asia Compliant with: Resistant to groundwater seepage during tropical rainy seasons in Southeast Asia

Steel Selection:

Choose high-quality structural steel (e.g., Q355B, S355GP, GR50) based on mechanical requirements.

Heating:

Heat billets/slabs to ~1,200°C for malleability.

Hot Rolling:

Shape steel into U-profile with rolling mills.

Cooling:

Cool naturally or with water sprays to achieve desired properties.

Straightening & Cutting:

Ensure dimensional accuracy and cut to standard or custom lengths.

Quality Inspection:

Conduct dimensional, mechanical, and visual tests.

Surface Treatment (Optional):

Apply painting, galvanization, or corrosion protection if needed.

Packaging & Shipping:

Bundle, protect, and load for transport.

Port and wharf construction: Steel sheet piles are used in port and wharf construction to form robust retaining walls, ensuring shoreline stability.

Bridge engineering: In bridge engineering, steel sheet piles serve as foundation support structures, improving load-bearing capacity and scour resistance.

Deep foundation pit support for underground parking lots: In the foundation pit support of underground parking lots, steel sheet piles provide safe and reliable lateral support, preventing soil collapse.

Water conservancy projects: In water conservancy projects, steel sheet piles are used for riverbank protection, dam reinforcement, and cofferdam construction, ensuring water management safety.

Port and Wharf construction

Bridge Engineering

Deep foundation pit support for underground parking lots

Water conservancy projects

Local Support: Assistance from our local branch and Spanish-speaking team for seamless communication.

Stock Availability: Ready inventory to meet project demands quickly.

Professional Packaging: Bundled, protected, and corrosion-resistant packaging to ensure safe handling.

Reliable Transportation: Efficient and secure logistics to deliver sheet piles safely to site.

Packaging of Steel Sheet Piles

Bundling: Arrange sheet piles neatly and secure with steel straps or strong ropes.

End Protection: Fit protective caps or wooden blocks on pile ends to prevent damage.

Corrosion Protection: Wrap with waterproof film, rust-preventive oil, or plastic if needed.

Transportation of Steel Sheet Piles

Loading: Use cranes or forklifts to load bundles onto trucks, flatbeds, or containers.

Securing: Ensure piles are stably stacked and firmly fastened to prevent shifting.

Unloading: At the construction site, unload and place piles orderly for easy use.

1: Do you supply steel sheet piles to the Americas market?

Answer: Yes, we supply high-quality steel sheet piles to North, Central, and South America. Our local branches and Spanish-speaking support ensure smooth communication and timely service for projects across the region.

2: How are your steel sheet piles packaged and shipped to the Americas?

Answer: Steel sheet piles are professionally bundled, fitted with protective end caps, and treated against corrosion if needed. We use secure logistics with trucks, flatbeds, or containers to ensure safe delivery to the construction site.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506