Industrial Prefab Portal Frame Workshop Steel Structures

Steel Structure are widely used in various building types and engineering projects, including but not limited to the following aspects:

Commercial buildings: Such as office buildings, shopping malls, and hotels. Steel structures offer large spans and flexible spatial designs, meeting the spatial requirements of commercial buildings.

Industrial plants: Such as factories, storage facilities, and production workshops. Steel structures offer strong load-bearing capacity and fast construction, making them suitable for industrial plant construction.

Bridge projects: Such as highway bridges, railway bridges, and urban rail transit bridges. Steel bridges offer advantages such as light weight, large spans, and fast construction.

Sports venues: Such as gymnasiums, stadiums, and swimming pools. Steel structures offer large, column-free designs, making them suitable for sports venue construction.

Aerospace facilities: Such as airport terminals and aircraft maintenance depots. Steel structures offer large spans and excellent seismic performance, making them suitable for aerospace construction.

High-rise buildings: Such as high-rise residential buildings, office buildings, and hotels. Steel structures offer lightweight structures and excellent seismic performance, making them suitable for high-rise buildings.

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What should you pay attention to when making a steel structure house?

1.The review of the rationality of organization is necessary

When installing rafters in a steel frame home, you must take into account the design and construction techniques of the attic house. The rebar must not be re-damaged during the production process and potential safety hazards must avoided.

2.Be Careful When Selecting

Steel Skilled craftsmen know how to build with different types of steel, but not all steel is suitable for house building? Please do not use hollow steel tube to keep structure stability, and you can’t directly paint the inside because it will rust.

3.Be Careful When Selecting

Clear Structural Arrangement. It shakes up and down when laden; and the shaking motion of the steel structure is pretty palpable. So when we archetect the house, we must fantasize, and calculate exactly not to make any vibrations and put visual beauity and solidity.

4.Be Careful When Painting

Painting It is recommended to paint the surface with anti-rust paint for rust protection after the steel frame has been welded in full because external factors may lead to oxidation. Rust will discolor the walls and ceilings and can even leading to safety risks.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

1. Embedded components (to stabilize the steel factory building structure)

2. Columns are typically made of H-shaped steel or C-shaped steel (typically two C-shaped steels are connected with angle steel).

3. Beams are typically made of C-shaped steel or H-shaped steel (the height of the center section is determined by the span of the beam).

4. Rods, typically C-shaped steel, but can also be channel steel.

5. There are two types of tiles. The first is single-piece tiles (colored steel tiles). The second is composite panels (polystyrene, rock wool, polyurethane). (Foam is filled between the two layers of tiles, providing warmth in winter and coolness in summer, while also providing sound insulation.)

PRODUCT INSPECTION

Steel structure precast engineering inspection mainly involves raw material inspection and main structure inspection. Among the steel structure raw materials that are often submitted for inspection are bolts, steel raw materials, coatings, etc. The main structure is subjected to weld flaw detection, load-bearing testing, etc.

nspection Scope:

Steel, welding materials, standard fasteners for connections, welding balls, bolt balls, sealing plates, cone heads and sleeves, anti-corrosion materials, steel structure welding, welded roof (bolt) welding, general fastener connections, high-strength bolt installation torque, component processing dimensions, steel component assembly dimensions, steel component pre-installation dimensions, single-story steel structure installation dimensions, multi-story and high-rise steel structure installation dimensions, steel grid structure installation dimensions, steel structure coating thickness, etc.

Inspection Items:

Appearance, nondestructive testing, tensile testing, impact testing, bend testing, metallographic structure, pressure-bearing equipment, chemical composition, weld material, welding materials, geometric shape and dimensional deviation, external weld defects, internal weld defects, weld mechanical properties, raw material testing, adhesion and thickness, appearance quality, uniformity, adhesion, bending resistance, salt spray corrosion resistance, wear resistance, impact resistance, chemical solvent corrosion resistance, heat and humidity resistance, weathering resistance, temperature cycling resistance, cathodic disbonding resistance, ultrasonic testing, mobile communication engineering steel tower mast structure, magnetic particle testing, mobile communication engineering steel tower mast structure, final torque testing of fasteners, fastener strength calculation, appearance defects, corrosion testing, structural verticality, actual load, strength, stiffness, and stability of structural components.

PROJECT

Our company always provides you with high qualiity products and best service for Steel Structure Workshop for South America, We have a professional group performing for your service. We attended the one of projects in the Americas for about 543,000 square meters on floor area and 20,000 tons of steel. After the completion, the project would be a steel-frame building complex with production, living, office, education and tour.

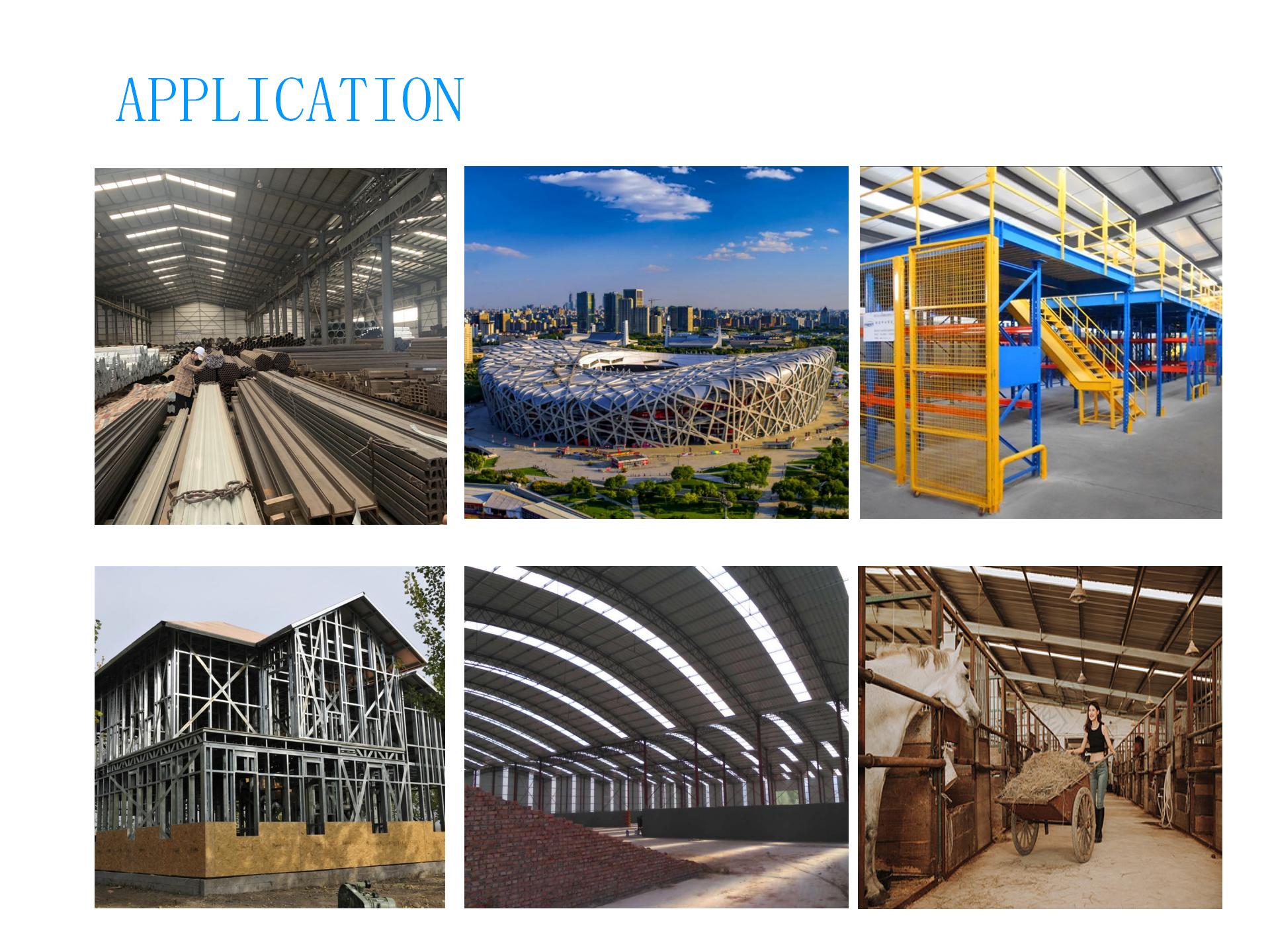

APPLICATION

1. Cut expense

Steel structures have reduced cost of production and maintenance as compared to conventional building construction. Furthermore, 98% of the components of a steel structure can be recycled into new structures without losing their mechanical properties.

2. Quick installation

The precise machining of steel structural components increases installation speed and allows the use of management software monitoring to speed up construction progress.

3. Health and safety

Warehouse Steel Structure components are produced in the factory and safely constructed on site by professional installation teams. The results of the actual investigation have proved that the steel structure is the safest solution.

There is very little dust and noise during construction because all components are pre-manufactured in the factory.

4. Be flexible

The steel frame can be modified to meet future requirements, the loads, the long span is full of the owner's demands and other structures cannot be reached.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Select an appropriate transportation method: Based on the amount and weight of the steel structure, select a suitable transportation method, such as flatbed trucks, containers, or ships. Take into account distance, time, cost, and any regulations related to the transportation.

Utilize proper lifting device: You should use proper lifting device to load and unload steel structure, like cranes, forklifts and loaders. Verify that the equipment employed can safely accommodate the weight of the sheet piles.

Fasten the load: The packaged stack of steel structure on the transport vehicle shall be adequately secured with strapping, bracing or any other suitable means to protect against shifting, sliding or falling on the way.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

COMPANY STRENGTH

CUSTOMERS VISIT