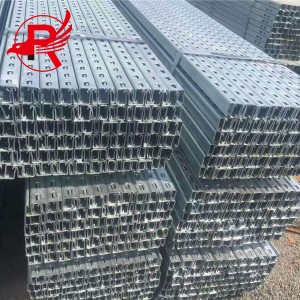

Photovoltaic Bracket Earthquake Resistant Bracket 41*41*2

Suitable for different sites: Photovoltaic brackets can adapt to different sites and land types, including flat land, mountains, deserts, wetlands, etc.

Product Detail

Product Detail

| Item | Specifications |

|---|---|

| Material | Q195 / Q235 / SS304 / SS316 / Aluminum |

| Thickness | 1.5 mm / 1.9 mm / 2.0 mm / 2.5 mm / 2.7 mm (12GA / 14GA / 16GA / 0.079'' / 0.098'') |

| Cross Section | 41×21 mm / 41×41 mm / 41×62 mm / 41×82 mm, slotted or plain (1-5/8''×1-5/8'', 1-5/8''×13/16'') |

| Standard | DIN / ANSI / JIS / ISO |

| Length | 2 m / 3 m / 6 m / customized (10 ft / 19 ft / custom) |

| Packing | 50–100 pcs wrapped in plastic bags |

| Finish Options | 1. Pre-galvanized steel 2. Hot-dip galvanized (HDG) 3. Stainless steel SS304 4. Stainless steel SS316 5. Aluminum 6. Powder coated |

| No. | Size (mm) | Size (inch) | Thickness (mm) | Gauge | Type | Surface Finish |

|---|---|---|---|---|---|---|

| A | 41×21 | 1-5/8×13/16" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| B | 41×25 | 1-5/8×1" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| C | 41×41 | 1-5/8×1-5/8" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| D | 41×62 | 1-5/8×2-7/16" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

| E | 41×82 | 1-5/8×3-1/4" | 1.0, 1.2, 1.5, 2.0, 2.5 | 20, 19, 17, 14, 13 | Slotted / Solid | GI, HDG, Powder Coated |

ADVANTAGE

Custom Strut C channels are widely utilized in steel construction for purlins and wall beams, and are also fabricatable into light roof trusses, bracings and additional steel building elements. They can be used for columns, beams, arms and other components used in the machinery and lightweight industrial equipment. C- shaped steels are produced by cold forming from the hot‐rolled steel plates, these steels have thin walls, are lightweight, have excellent cross‐sectional strength and good durability. It can save 30 percent material while obtaining the same strength comparing with conventional channel steel.

With construction on the rise and the emergence of green building materials, a lot of technological improvements have been made on galvanized C channels. They are also widely used for wall beams in buildings because of these major advantages:

1.Lightweight: C channels, formed from hot-rolled steel plates, impose less structural loads when compared to concrete, which also accelerates the building process.

2.Stable and Flexible: Its good internal design enables it to endure bigger oscillations and its excellent natural force resistance allows it to compete against the nature.

3.Time and energy saving: They save material in welding, reduce labor and resources, are easy to process and they can be disassembled and recycled.

PRODUCT INSPECTION

In order for galvanised C channel plants to run smoothly and live up to expectations, testing and analysis on a consistent basis is a must. Areas to evaluate are:

Power Generation Efficiency: The Power Generation Efficiency of a photovoltaic system can be calculated by measuring actual power output and comparing with that predicted from theoretical power output.

1.Performance of Components: Photovoltaic components may be monitored for performance and degradation for given time intervals by measuring current, voltage and power.

2.System Durability: Test the durability and life time of a system, such as inverters, cables and other major components.

3.Environmental Considerations: Identify potential environmental impacts of construction and operation and demonstrate compliance with applicable environmental laws and standards.

PROJECT

We at C-Channel Steel Suppliers competed in the largest solar project in South America by providing brackets and design assistance. We delivered 15,000ton of photovoltaic brackets for the project. These brackets applied high-end domestic technology, which promoted the development of South American photovoltaic industry and the living standard of local society.

The project includes a 6 MW photovoltaic power plant and a 5 MW/2.5 h battery energy storage system, developing approximately 1,200 kWh per year. The system shows excellent photoelectric conversion efficiency and stability.

Application

Photovoltaic mounting structures are typically made of aluminum alloy, stainless steel, or carbon steel. Such materials provide corrosion and oxidation resistance, strength, and weather and environmental resistance, they keep brackets stable and durable.

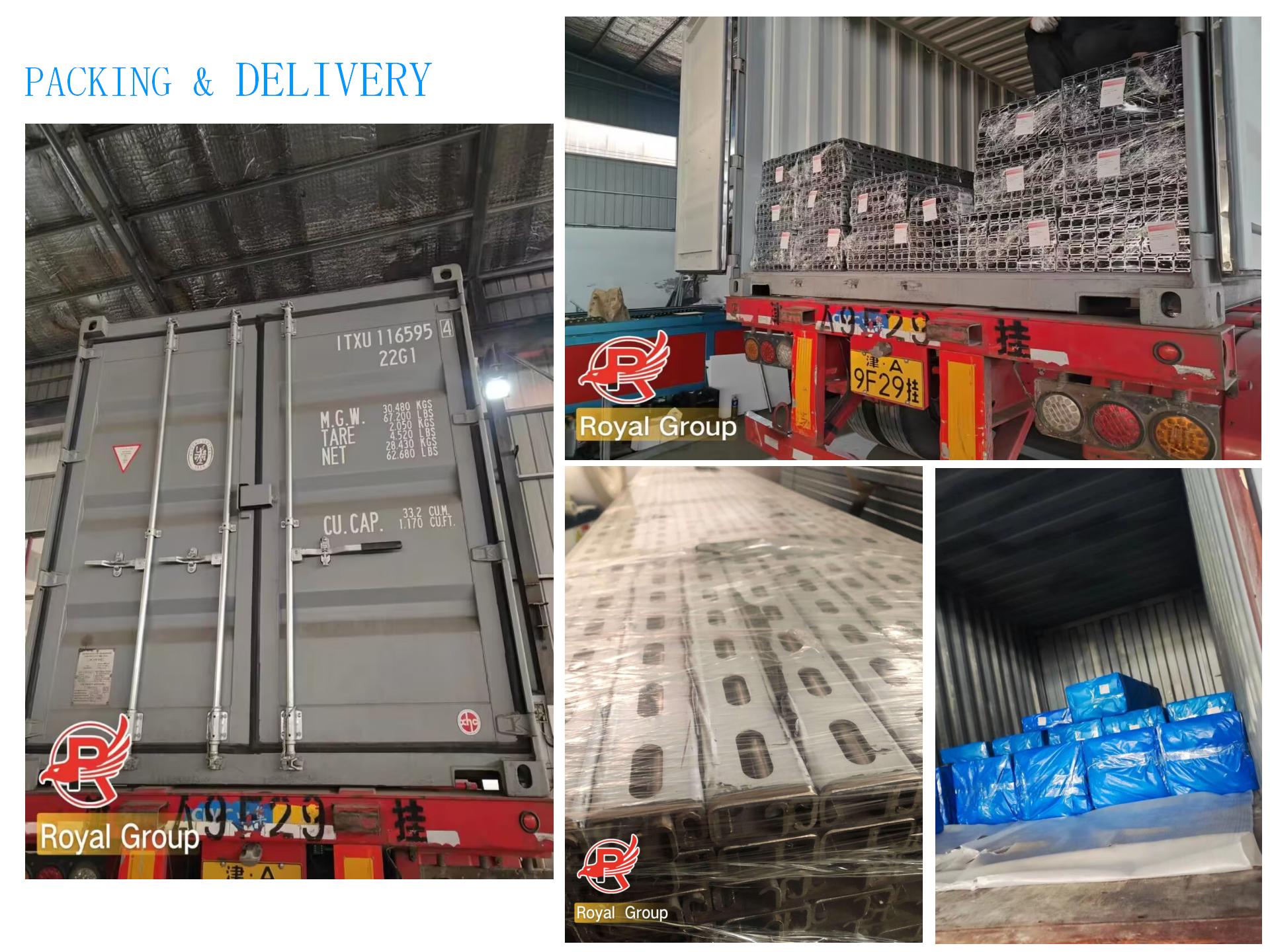

Packaging & Shipping

Packaging:

Foam Box: High strength cardboard/wooden boxes protect the module and make handling easier.

Wood Box: Stronger protection for the heavy goods, but less space and environmental friendly.

Pallet: Modules are put on corrugated cardboard pallets for a solid easy transport.

Plywood: Attach the module with plywood to avoid collisions or distortion during transportation.

Transport:

Land: Good for distance ≤ 1000km; avoid collision and hire professional logistics.

Sea: Appropriate for long-distance, cross-province or cross-border transportation; keep the goods well packed and moisture-protected.

Air: The fastest way for cross-border delivery; costs more, care should be taken.

COMPANY STRENGTH

Made in China – high quality and dependable service

1.Scale Advantage: Large Supply Chain, Integrated Steel Mill for Great Scale Production and Services.

2.Product Variety: Various products such as Steel Structure, Rail, Sheet Pile, Photovoltaic Bracket, Channel Steel, Silicon Steel Coil etc.

3.Stable Supply: Stable production and supply for the massive order.

4.Brand Strength: Strongly reputable and well established firm in the market.

5.One stop service: customizad, manufacture, transport on one stop.

6.Affordable Quality: The best quality steel at best price.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. Who We Are

Based in Tianjin, China since 2012, serving Southeast & South Asia (40%), Europe (20%), Africa (10%), North America (25%), South America (5%). Office staff: 51–100.

2. Quality Assurance

Pre-production samples before mass production; final inspection before shipment.

3. Products

Steel pipes, iron angles, iron beams, welded steel structures, perforated steel products.

4. Why Choose Us

High quality, competitive prices, fast delivery, excellent service, products meet various standards.

5. Services

Delivery: FOB, CFR, CIF; Payment: USD/CNY, T/T, L/C; Languages: English, Chinese.