Prefabricated Steel Structure Building for Workshop

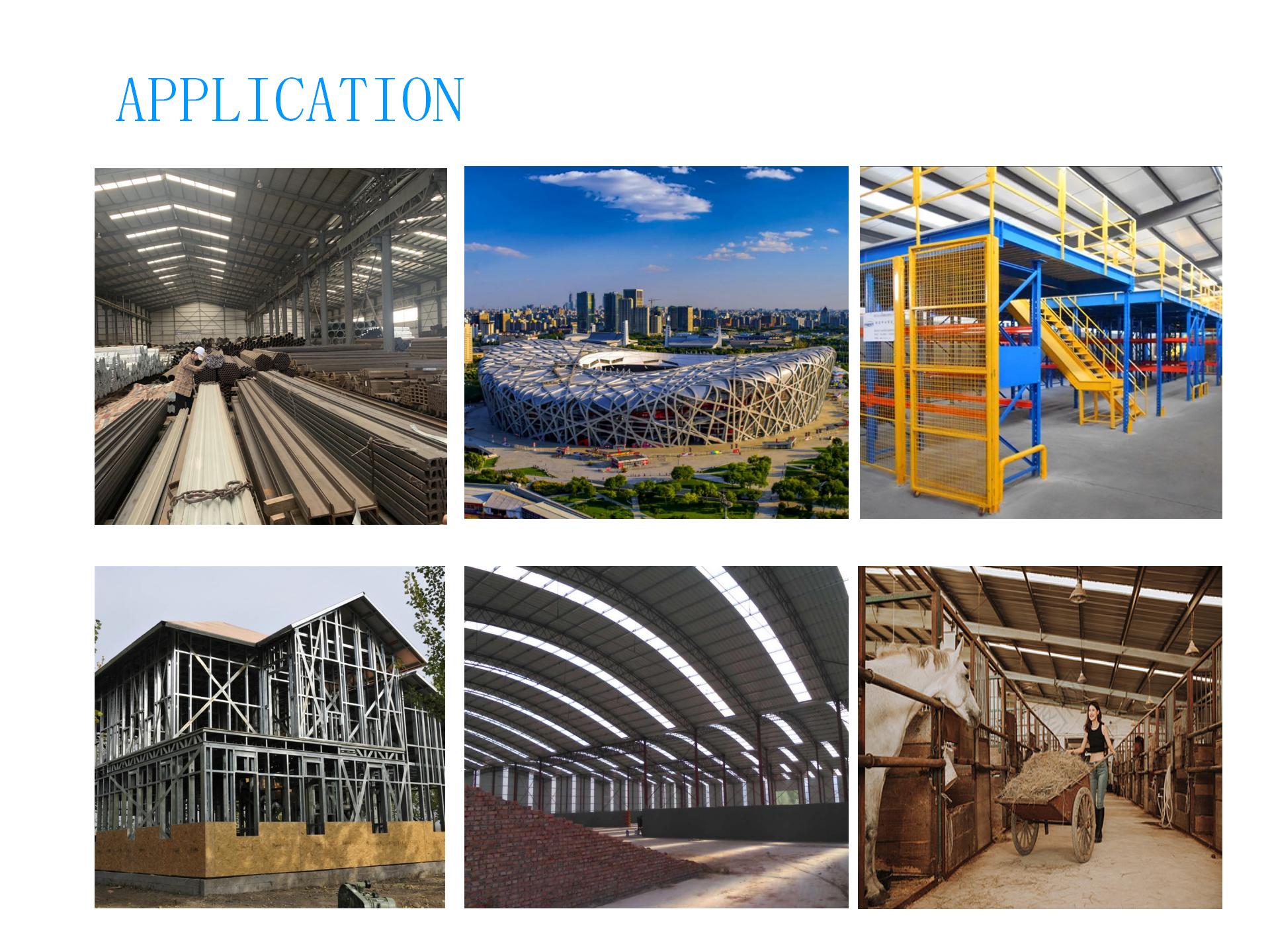

Steel structures are widely used across various projects due to their strength, flexibility, and efficiency:

Commercial Buildings: Offices, malls, and hotels benefit from large spans and adaptable layouts.

Industrial Plants: Factories, warehouses, and workshops gain from high load capacity and rapid construction.

Bridges: Highway, railway, and urban transit bridges use steel for lightweight, long spans, and quick assembly.

Sports Venues: Stadiums, gyms, and pools enjoy wide, column-free spaces.

Aerospace Facilities: Airports and hangars require large spans and strong seismic performance.

High-Rise Buildings: Residential and office towers benefit from lightweight, earthquake-resistant structures.

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

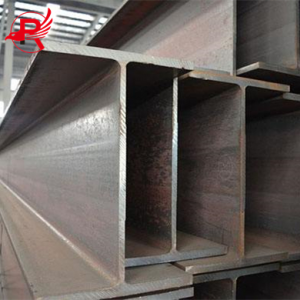

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What precautions should be taken when building a steel-framed house?

-

Structural Integrity: Align rafter layout with loft design and avoid damaging steel during construction to ensure safety.

-

Material Selection: Use appropriate steel types; avoid hollow pipes and uncoated interiors to prevent rust.

-

Clear Layout: Perform precise calculations to minimize vibration and maintain a strong, visually appealing structure.

-

Protective Coating: Apply anti-rust paint after welding to prevent corrosion and ensure safety and durability.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

1.Concealed Components: Reinforce the factory building.

2.Columns: Usually H or paired C (like 2 C’s back to back) box steel with angle steel.

3.Beams: Apply H, or C steel beams, beam height is related to the beam span.

4.Bars: Mostly C- shape steel bars, occasionally channel steels.

5.Roof Shingles: Single-piece color steel tiles, or insulated composite panels (polystyrene, rock wool, or polyurethane) for thermal and acoustic insulation.

PRODUCT INSPECTION

Inspection of prefabricated steel structures primarily involves raw material inspection and main structure inspection. Bolts, steel materials, and coatings are often inspected. The main structure undergoes weld flaw detection and load-bearing tests.

Contents of Inspection:

Inspection of steel, welding consumables, fasteners, weld balls, bolt balls, sealing plates, cone heads, sleeves, coatings, welded constructs (including roofs), installation of high strength bolts, component dimensions, assembly and pre-installation dimensions, single and multistory constructs, steel grids and coat thickness.

Inspection Items:

It involves visual inspection, non-destructive testing, tensile, impact and bend tests, metallography, load test, chemical composition, weld quality, dimensional accuracy, external and internal defects of the weld, mechanical properties of the weld, adhesion and thickness of the coating, homogenuity, corroision and wear resistance (salt spray, chemical, aging) , heat and moisture resistance, effect of temperature cycling, ultrasonic and magnetic particulate testing, torque and strength of fasteners, verticality of the structure, actual loading, strength and stiffness of structure, and of entire system stability.

PROJECT

Our company often exports Steel Structure Workshop products to the Americas and Southeast Asian countries.We finished a large-scale work in the Americas that spanned 543,000 m2 and 20,000 tons of steel, producing a multitier steel structure complex for manufacturing, living, offices, education, and tourism.

APPLICATION

1.Affordable: The production and maintenance costs of steel structures are low, and 98% of components can be recycled without loss of strength.

2. Quick assembly: Precision-engineered parts and software bring construction up to speed.

3.Clean and safe: With components machined at the factory, assembly on-site is safe, and dust and noise are kept to a minimum.

4.Adaptable: Steel buildings can be changed or expanded as the needs grow in the future.

PACKAGING AND SHIPPING

Packaging: Based on your requirements or the most appropriate packaging method.

Transportation:

Transportation: Choose the means of transportation (flatbed, container, or ship) according to size, weight, distance, cost and regulations.

Lifting: Utilizing cranes, forklifts, or loaders of sufficient capacity to safely handle the load.

Load securing: Strap steel stacks or use braces to secure stacks to prevent movement in transit.

COMPANY STRENGTH

Made in China-Premium Service, High Quality, Global Reputations.

Size: The whole factory and supply chain provide customers with efficient production, purchasing and integrated service.

Range: You can flexibly choose from a whole range of products, including steel structures, rails, sheet piles, PV brackets, channel steel, silicon steel coils and many more.

Stable Supply: Stable production lines guarantee stable supply, even for large orders.

Strong Brand: Famous brand with popular sale.

One Stop Service: Customization, production, transport in one.

High Quality and Reasonable Price.

*Send the email to [email protected] to get a quotation for your projects

COMPANY STRENGTH

CUSTOMERS VISIT