Click to get a FREE 3D Design and Quote within 24 hours!

Prefabricated Steel Structure Products for Steel Structure Supermarket Projects

APPLICATION

Commercial and public buildings:Prefabricated steel frames are a contemporary and versatile product used for commercial building construction, such as in office blocks, steel structure supermarkets and sports halls.

Industrial factories and plat production:Industry load bearing work such as H-beam, I-beam, steel plate and other heavy steel beams are supported. And they are the right choice for equipment platforms, production lines and factory floors.

Warehouses and Logistics Centers: Prefabricated steel buildings provide fast, cost-effective warehouse and distribution center construction. Pre-fabricated parts facilitate rapid erection and ensures strength and durability.

Bridges and Infrastructure Projects: Amongst all the materials used in construction, the use of steel is most critical for steel structure bridges, roads, and energy infrastructure, as it can meet complex engineering requirements on strength, accuracy, and flexibility.

PRODUCT DETAIL

Core steel structure products for bridge construction

1. Main steel structure Supermarket type

| Product Type | Specification Range | Primary Application | Structural Advantages |

|---|---|---|---|

| Portal Frame System | Span: 12–60 m Eave Height: 6–15 m |

Designed to create wide, column-free interiors for warehouses, factories, and logistics facilities | Lightweight structural design with high strength; rapid on-site assembly; economical solution for industrial buildings |

| Steel Frame System | Height: 1–20+ stories Span: 6–30 m |

Multi-level structural framework composed of beams and columns, ideal for commercial complexes and office buildings | Excellent structural stability; adaptable floor layouts; compatible with composite slab systems |

| Steel Truss Structure | Span: 15–120 m | Long-span roof and covering systems distributing loads through triangular members; commonly used for stadiums and exhibition halls | Efficient load transfer; optimized steel consumption; suitable for large-span architectural projects |

| Space Frame Structure | Span: 20–100 m | Three-dimensional grid system providing enhanced structural integrity and lightweight performance | High stiffness-to-weight ratio; modular assembly; flexible architectural design possibilities |

| Heavy Steel Structure | Column Type: H-section / Box section Span: 20–80 m |

Engineered for heavy-duty industrial facilities supporting cranes, heavy equipment, and machinery loads | Thick steel profiles; superior load-bearing capacity; ideal for large-scale industrial plants |

2. Enclosure system products (weatherproof + anti-corrosion)

| Product Type | Specification Range | Main Application | Structural Advantages |

|---|---|---|---|

| Roofing Panels | Thickness: 0.4–1.2 mm Material: Galvanized Steel / Alu-Zinc / PPGI |

Used as exterior roof cladding to provide weather protection and structural load distribution for steel buildings | Excellent wind resistance; corrosion-protected surface coating; lightweight for efficient installation |

| Wall Cladding Panels | Thickness: 0.4–1.0 mm Type: Single Sheet / Insulated Sandwich Panel |

Serves as the outer enclosure system for industrial and commercial steel structures | Optional thermal insulation; waterproof and fire-rated solutions; modular design for quick assembly |

| C & Z Purlins | C100–C300 / Z120–Z300 Thickness: 1.5–3.0 mm |

Secondary structural members supporting roof and wall panels while transferring loads to the main steel frame | High-strength cold-formed steel; precision punching for bolted connections; galvanized finish for extended durability |

| Bracing System | Round Bar: Φ12–Φ20 Angle Steel: L50×5 – L100×8 |

Provides lateral stability and reinforces structural rigidity against wind and seismic loads | Flexible connection methods (bolted or welded); efficient force distribution; corrosion-resistant treatment |

| Tie Beams & Girts | H-section / Channel Steel Custom profiles available |

Connects primary structural elements and enhances overall building stability | Improves load transfer performance; strengthens structural integrity; adaptable to various building designs |

3. Supporting auxiliary products (localized construction adaptation)

| Product Type | Specification Range | Primary Function | Structural Advantages |

|---|---|---|---|

| Expansion Joint Systems | Modular steel or elastomeric joints Width: 50–200 mm |

Designed to absorb thermal expansion and structural displacement in steel buildings and long-span constructions | Durable materials with flexible movement capacity; optional corrosion-resistant finishes; suitable for varying climate conditions |

| Guardrails & Safety Barriers | Steel channel or tubular sections Height: 900–1200 mm |

Provides fall protection and safety enclosure for platforms, walkways, and elevated steel frameworks | Hot-dip galvanized or coated surface; high impact resistance; modular and easy-to-install components |

| Access Ladders & Maintenance Platforms | Galvanized ladders (Φ32–Φ50) Platforms (L50×5 angle steel) |

Ensures safe access for inspection and maintenance of industrial steel facilities | Anti-slip surface design; lightweight prefabricated structure; efficient on-site installation |

| Drainage & Water Management Systems | Steel grating (Φ12 bars) Gutter channels (C-section 100×50–150×75) |

Controls rainwater flow and prevents water accumulation on roofs and structural surfaces | Galvanized or coated for corrosion resistance; durable under heavy rainfall; seamlessly integrated with roofing systems |

| Lighting & Utility Support Structures | Steel poles, mounting brackets, cable trays | Supports lighting fixtures, power lines, and utility systems within steel buildings | Pre-treated anti-corrosion surface; modular replacement design; compliant with industrial installation standards |

STEEL STRUCTURE PROCESSING

Cutting

Plasma and Flame Cutting for Thick Steel Plate.

Precision Shearing Machines for Thin Plates.

Guarantees the right size and the clean cut edge.

Forming

Cold forming or press brake forming of purlins, gutters and trims

Roll forming machines for round members and round columns

Ensures structural propagation and dimensional stability

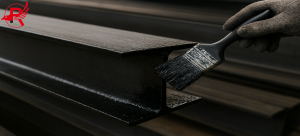

Welding

Submerged arc welding is utilized for h-beams and heavy columns

Arc welding of plates and structural joints by hand

CO₂ gas shielded welding on thin sections

Welding Inspection to Full Confidence in the Structural Integrity

Hole Processing

CNC drilling for precise bolt hole match-up

Punch press machines for small batch parts

High precision positioning makes the on-site installation easy

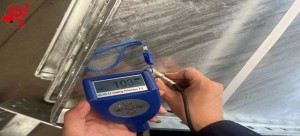

Surface Treatment

Shot blasting or sand blasting for rust removal

Grinding of welds and polishing of surfaces/finishes

Hot-dip galvanising of the bolts and supporting parts for an increased corrosion protection

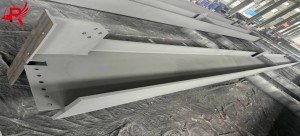

Trial Assembly

Prefabrication of columns, beams and bracing systems

Dimension verification with professional measuring instruments

InKine Disassembly After inspection for safe shipmetnte

STEEL STRUCTURE TESTING

| Test Type | Standard(s) | Purpose / Notes |

|---|---|---|

| Mechanical & Structural Strength Test | ASTM A370 / EN 10002 | Verifies tensile strength, yield strength, and load-bearing capacity of beams, columns, and trusses under structural loads. |

| Weld Quality Inspection | AWS D1.1 / ISO 5817 | Ensures weld penetration, continuity, and defect control at critical structural joints for long-term safety. |

| Corrosion Resistance (Salt Spray Test) | ASTM B117 / ISO 9227 | Evaluates durability of galvanized and coated components under aggressive and marine environments. |

| Dimensional Tolerance & Fabrication Inspection | EN 1090 | Confirms prefabricated steel members meet design tolerances for accurate on-site assembly. |

| Bolt & High-Strength Fastener Test | ASTM F606 / EN 14399 | Validates tensile strength, preload capacity, and reliability of structural bolting systems. |

| Coating Adhesion & Impact Resistance Test | ASTM D3359 / ASTM D2794 | Assesses coating bonding strength and resistance to mechanical damage during transport and installation. |

SURFACE TREATMENT

PACKAGING AND SHIPPING

Trusses and Girders

Steel strapping and wooden ledgers are attached. It is wrapped with moisture proof and anti rust layer to avoid damage in the transport.

Roof & Wall Panels

Palletized with spacers to protect coated surfaces. Sleeve wrapped in water-proof and UV-protection film for long-distance shipment.

Columns & Beams

Wrapped in protective padding and rust proofed. Lifting points are clearly indicated for safe handling and installation.

Bracing, Bolts & Anchors

Sealed wooden boxes or steel drums with moisture barrier. Clearly identified for straightforward assembly on location.

Transport

Transport by: air, sea, land (sea freight container, truck, rail transportation, road transportation). Modular loading increases security and efficiency.

WHY CHOOSE OUR STEEL STRUCTURES?

Custom Engineering

We provide tailored bridge designs including truss, arch, and box girder systems, optimized according to span requirements, load capacity, and site-specific conditions.

Certified Materials

All structural steel components comply with international standards such as ASTM, EN, and AASHTO. Options include hot-dip galvanizing or weathering steel to ensure long-term corrosion resistance.

Precision Manufacturing

Prefabricated modular units are factory-produced under strict quality control, ensuring accurate dimensions, faster installation, and reduced on-site adjustments.

Durability & Climate Resistance

Our bridges are engineered to perform reliably in tropical climates, high-wind regions, seismic zones, and under heavy traffic loads, ensuring extended service life.

Ready to start your project?

FAQ

Q1: What bridge types do you offer?

A: We design and manufacture truss, arch, box girder, and pedestrian or cycling bridges. All structures are fully customized to meet specific span and load requirements.

Q2: Which international standards do your bridges comply with?

A: Our components are produced in accordance with ASTM, EN, ISO, and AASHTO standards. Surface protection options include hot-dip galvanizing and weathering steel for enhanced durability.

Q3: Can your bridges perform in tropical or seismic environments?

A: Yes. Our bridge systems are engineered to withstand high winds, seismic activity, heavy traffic loads, and humid tropical climates.

Q4: How are bridge components packaged for delivery?

A: All parts are securely bundled or crated with anti-corrosion protection and clear identification markings to ensure safe transport and efficient on-site installation.

Q5: What is the typical production lead time?

A: Standard delivery ranges from 8 to 20 weeks depending on project scale and design complexity. Prefabricated modular construction helps shorten installation time on site.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506