Prefabricated Steel Structures Are Cheap And High Quality

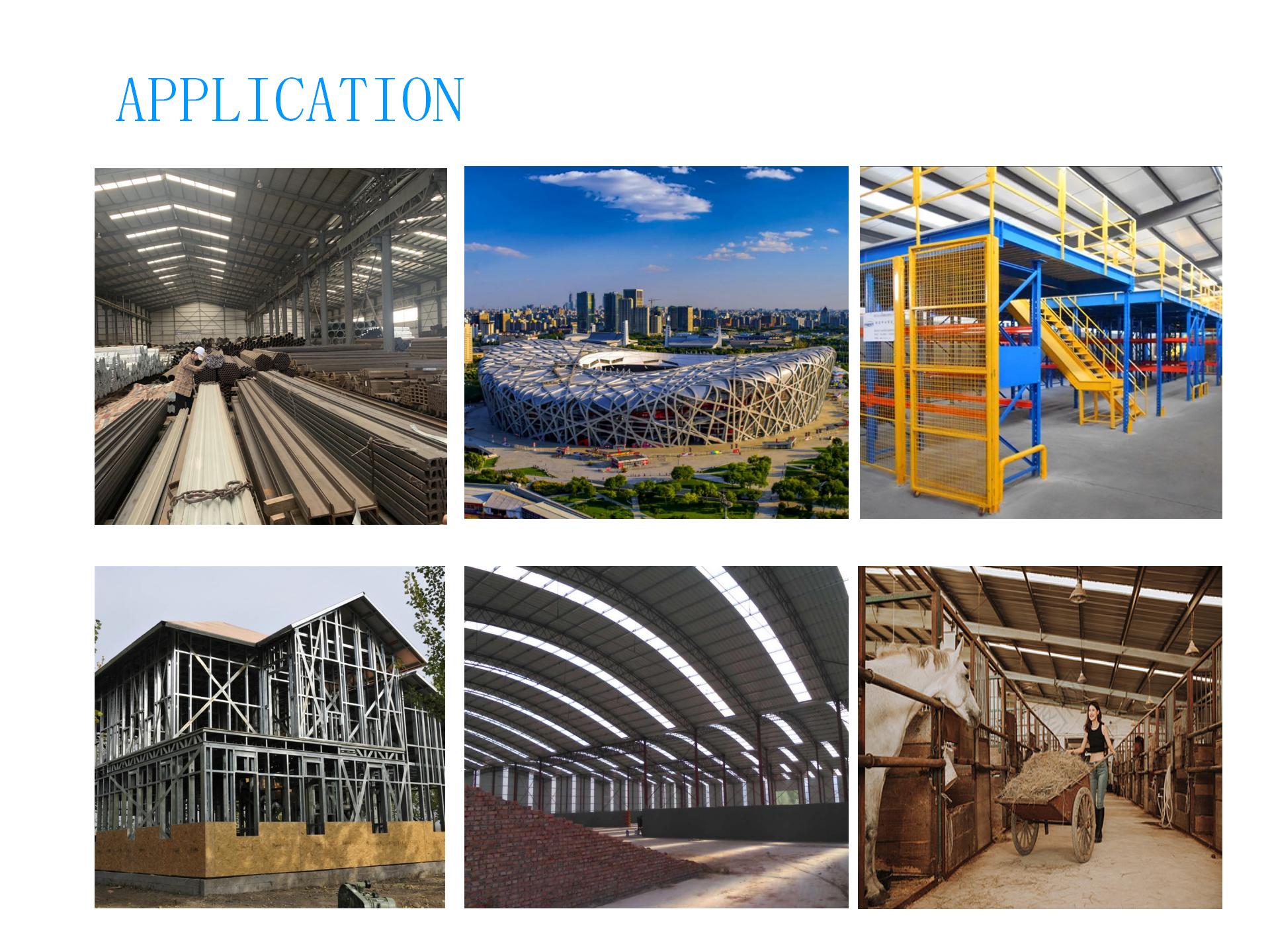

Applications of Steel Structures

Commercial building: Office Mall, hotel – the large-span, flexible layout.

Factories, workshops and warehouses: Heavy duty load bearing and rapid building.

Bridges: Highway and railway and city transit bridges – lightweight, long-span, quick erection.

Sports Theaters: Racquetball, stadiums, swimming - pools – big, column-free spaces.

Air Force Zoom Space:Home Air Force Facility Standards Airport Terminals, Maintenance Warehouses-Sizespaces And Earthquake-Resistant.

Tall buildings: Residential, business office, and hotel stack - light weight and seismic resistant.

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

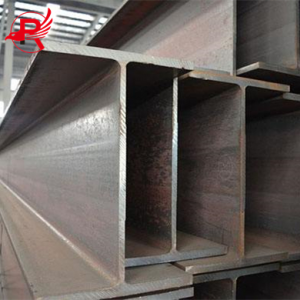

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

When Constructing a Steel Frame House

1.Rational Structure: Design rafters in relation to architectural style and floor plan of the attic without secondary damage and harm to life.

2.Steel Choice: Select appropriate steel (do not use hollow pipes) and treat it adequately to prevent rust and to keep the structure integrity.

3.Simple Structural Layout: Carefully analyze and calculate stresses to minimize vibration and to provide a stable, pleasing appearance.

4.Painting & Protection: Paint with anti-rust paint after welding to prevent rust on the surface of walls and ceilings and to keep safety.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

1.Embedded Components:

They fix the stability of the factory building.

2.Columns:

At least H-shape steel or paired C-shape steel with angle steel.

3.Beams:

Normally H or C shape steel, height depends on the span.

4.Rods:

Usually c-shaped steel, occasionally channel steel.

5.Roofing Tiles:

Single-layer: Color steel tiles.

Composite: Polystyrene or rock wool or polyurethane boards in combination with foam for thermal insulation and sound proofing.

PRODUCT INSPECTION

Steel structure precast engineering inspection mainly involves raw material inspection and main structure inspection. Among the steel structure raw materials that are often submitted for inspection are bolts, steel raw materials, coatings, etc. The main structure is subjected to weld flaw detection, load-bearing testing, etc.

Inspection Scope:

-

Materials: Steel, welding materials, fasteners, bolts, sealing plates, sleeves, coating materials.

-

Structural Components: Welding projects, roof and bolt welding, fastener connections, steel component dimensions, assembly and pre-assembly measurements.

-

Installation & Coating: Single-layer, multi-layer, high-rise, and steel grid structures; coating thickness.

Test Items:

-

Mechanical & Material Tests: Tensile, impact, bending, pressure-bearing, chemical composition, metallographic structure, weld mechanical properties.

-

Non-Destructive Testing (NDT): Ultrasonic, magnetic particle, external and internal weld defects.

-

Coating & Durability: Thickness, adhesion, uniformity, corrosion resistance (salt spray, chemical, moisture, heat), abrasion, impact, weather resistance, temperature variation, cathodic stripping.

-

Structural Checks: Appearance, geometric dimensions, verticality, load-bearing capacity, strength, stiffness, stability.

-

Fastener Testing: Final torque, strength calculations, anti-corrosion checks.

-

Special Structures: Mobile communication steel towers and mast structures

PROJECT

Our company regularly sells to the North and South America and Southeast Asia markets. A highlight project in the Americas for approximately 543,000 m2 with 20,000 tons of steel. After the end, a full range of production, living, office, education and travel for a steel structure complex.

APPLICATION

-

Cost Reduction: Lower production and maintenance costs compared to traditional buildings. About 98% of steel components can be reused without losing mechanical strength.

-

Fast Installation: Precision-machined components speed up construction, and project management software can further optimize progress.

-

Health & Safety: Factory-made components are safely installed on-site by professionals, minimizing dust and noise. Studies confirm steel structures are among the safest building solutions.

-

Flexibility: Easily modified to meet future needs, including load adjustments and expansions that are difficult for other structures to achieve.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Choose the Appropriate Mode of Transport: Consider the size, weight, distance, time, cost, and regulations when choosing transport, among other things, including flatbed trucks, containers, or ships.

Employ the Right Equipment for Lifting: Crane, forklift or loader that can safely handle the weight of the steel structures to load and unload.

Tie It Down: Strap down, brace, or otherwise secure stacks so they won’t move, slip or fall on the road.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects