GB Q235B, Q345B, Q390, and Q420 steel I-beams are high-strength structural beams widely used in buildings, bridges, industrial facilities, and heavy-load support applications.

Products

-

Hot Selling Sheet Pile Hot Rolled z Type Sy295 Sy390 Steel Sheet Piles

Steel sheet piles are long structural sections with interlocking connections, commonly used as retaining walls in waterfront structures, cofferdams, and other soil- or water-retaining applications. Made of steel for strength and durability, their interlocking design enables continuous walls, providing efficient support for excavations and structural projects.

-

All Round Scaffold Ring Lock Scaffolding Layher Ringlock Scaffold System

Disc scaffolding is the most widely used type today, consisting of uprights, crossbars, and diagonal bars assembled with fittings. Most tubes are hot-dip galvanized, preventing rust and breakage over long-term storage. It offers economy, convenience, speed, and safety, making it suitable for vertical work, peripheral safety nets, overhead installation, and indoor decoration at various floor heights.

-

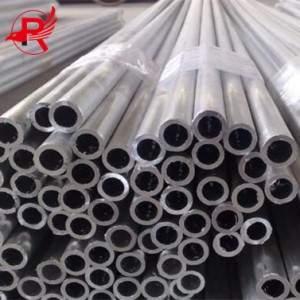

Customized 2024 3003 6082 7005 7075 Extrusion Aluminum Seamless Aluminum Tube Pipe for industry

Aluminum Pipe and Tube are Light Weight, Corrosion Free, High Conductivity and Excellent Machinability, these properties make Aluminum Pipe/Tube the Best Choice for all Industrial Uses.

-

Aluminum Tube Supplier 6061 5083 3003 Anodized Round Pipe

Aluminum pipes are lightweight, corrosion-resistant, and highly conductive, making them ideal for diverse industrial applications.

-

Cold Formed EN 10025 S235 / S275 / S355 6m-18m U-shaped Steel Sheet Pile

Cold-formed U-shaped steel sheet piles in S235, S275, or S355 steel, 6–18 m long, ideal for retaining walls, cofferdams, and foundations.

-

Cold Formed GB Q235b / Q345b / Q390 / Q420 6m-18m U-shaped Steel Sheet Pile

These U-shape Steel Sheet Piles are cold formed based on GB standard and can be offered in high strength grades Q235b, Q345b, Q390 and Q420. They are used for retaining walls, foundations, cofferdams and many other civil engineering works and are supplied in lengths from 6m to 18m. The Cold Formed U Pile design provides consistent thickness and interlock mechanism, high durability in soil and water condition.

-

S275 S355 S390 400X100X10.5mm U Type 2 Type 3 Carbon Ms Hot Rolled Metal Steel Sheet Piling for Construction

U Type 2 steel sheet piling is a widely used material for earth retention and excavation support. It is made of high-strength steel and features a U-shaped cross-section, providing structural stability and durability. U Type 2 sheet piles are designed to interlock with one another, creating a continuous wall for various construction applications such as waterfront structures, cofferdams, and retaining walls. The versatility and strength of U Type 2 steel sheet piling make it a popular choice for civil engineering projects requiring efficient and reliable earth retention solutions.

-

Hot Rolled ASTM A328 JIS A5528 SY295/SY390/SY490 6m-18m AZ PZ NZ Z-shaped Steel Sheet Pile

Z-typed steel sheet pile is a good-performance structural section which finds broad applications in civil engineering and building construction. The shape of the Z-shaped steel sheet pile and its interlock give an outstanding lateral load resistance, stability and durability, for that reason they are used toworkouts walls construction, waterside, ports, and extream deep excavations.

-

Cold Formed ASTM A328 JIS A5528 SY295/SY390/SY490 6m-18m U-shaped Steel Sheet Pile

Cold-rolled U- shape steel sheet pile is designed for tough structural demand in civil engineering and building application. They have higher strength and can be available in SY295, SY390 and SY490 grades. These piles are manufactured to ASTM A328 and JIS A5528 standards ensuring the piling being of the best quality.

-

-

EN 10025 S235 / S275 / S355 Steel I beam/IPE/IPN

EN 10025 is a European standard for hot-rolled structural steel, which specifies the chemical composition, mechanical properties, and testing methods for carbon steel and low-alloy high-strength steel.

-

API 5L Grade B X42 X46 X52 X60 X65 X70 X80 Seamless Steel Pipe

API 5L Steel Pipes (Grade B/X42-X80) – Professional Solution for Central America Oil & Gas Pipelines