Products

-

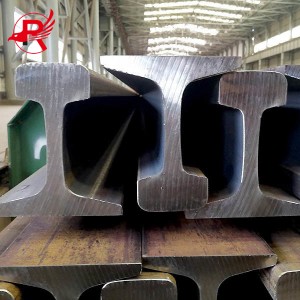

Professional Custom GB Standard Steel Rail Price Concessions Building Residential Construction

Steel rails are track components used on railway transportation systems such as railways, subways, and trams to support and guide vehicles. It is made of a special kind of steel and undergoes specific processing and treatment processes.Rails come in different models and specifications, and the corresponding models and specifications can be selected as needed to meet the needs of specific railway transportation systems.

-

GB Standard Steel Rail Material Construction Construction

Steel rails are track components used on railway transportation systems such as railways, subways, and trams to support and guide vehicles. It is made of a special kind of steel and undergoes specific processing and treatment processes.Rails come in different models and specifications, and the corresponding models and specifications can be selected as needed to meet the needs of specific railway transportation systems.

-

GB Mill Standard 0.23mm 0.27mm 0.3mm Silicon Steel Sheet Coil

Silicon steel, also known as electrical steel, is a special type of steel that is designed to exhibit specific magnetic properties. It is commonly used in the production of transformers, electric motors, and other electrical equipment.

The addition of silicon to the steel helps to enhance its electrical and magnetic properties, making it a suitable material for applications where low core losses and high magnetic permeability are required. Silicon steel is typically manufactured in the form of thin, laminated sheets or coils to minimize eddy current losses and improve the overall efficiency of electrical devices.

These coils may undergo specific annealing processes and surface treatments to further optimize their magnetic characteristics and electrical performance. The precise composition and processing of silicon steel coils can vary based on the intended application and performance requirements.

Silicon steel coils play a crucial role in the efficient and reliable operation of various electrical devices and are essential components in the generation, transmission, and use of electrical power

-

Sy290, Sy390 JIS A5528 400X100X10.5mm Type 2 U Type Steel Sheet Pile for Construction

As a commonly used infrastructure material, the main role of steel sheet piles is to form a support system in the soil to support the weight of buildings or other structures. At the same time, steel sheet piles can also be used as basic materials in engineering structures such as cofferdams and slope protection. Steel sheet piles are widely used in construction, transportation, water conservancy, environmental protection and other fields

-

Oem Custom Punching Processing Steel Products Stamping Bending Parts Service Sheet Metal Fabrication

Steel processed parts is on the basis of steel raw materials, according to the product drawings provided by customers, customized and manufactured product production molds for customers according to the required product specifications, dimensions, materials, special surface treatment, and other information of the processed parts. Precision, high-quality, and high-tech production is carried out according to customer requirements. If there are no design drawings, it’s okay. Our product designers will design according to the customer’s needs.

-

Custom Metal Fabrication Service Steel Fabrication Stamping Laser Cutting Part Sheet Metal Fabrication

Laser cutting is a technology that uses a high-powered laser to cut materials such as metal, wood, plastic, and glass. The laser beam is focused and directed by a computer-controlled system to precisely cut and shape the material. This process is commonly used in manufacturing, prototyping, and artistic applications due to its high level of precision and versatility. Laser cutting is known for its ability to produce intricate designs and complex shapes with minimal material waste.

-

ASTM H-Shaped Steel h Beam Carbon h Channel Steel

ASTM H-Shaped Steel also known as H-sections or I-beams, are structural beams with a cross-section resembling the letter “H.” They are commonly used in construction and civil engineering projects to provide support and stability for structures such as buildings, bridges, and other large-scale infrastructures.

H-beams are characterized by their durability, high load-bearing capacity, and versatility, making them suitable for a wide range of applications. The design of H-beams allows for efficient distribution of weight and forces, making them an ideal choice for constructing long-span structures.

Additionally, H-beams are often used in combination with other structural elements to create rigid connections and support heavy loads. They are typically made from steel or other metals, and their size and dimensions can vary depending on the specific requirements of a project.

Overall, H-beams play a crucial role in modern construction and engineering, providing essential support and stability for a variety of architectural and industrial applications

-

Custom Meta Steel Profile Cutting Service Sheet Metal Fabrication

Our metal cutting services cover multiple processes, including laser, plasma, and gas cutting, enabling precise processing of metals such as carbon steel, stainless steel, aluminum, and copper. We support customization of thin and thick plates ranging from 0.1mm to 200mm, meeting the high-precision cutting needs of industrial equipment, building components, and home decoration. We offer door-to-door service or online ordering to ensure efficient delivery and meticulous quality.

-

Prefabricated Building Steel Structure Warehouse Building Factory Building

Steel structure is a framework made of steel components, primarily used in construction to support buildings, bridges, and other structures. It typically includes beams, columns, and other elements designed to provide strength, stability, and durability. Steel structures offer various advantages, such as high strength-to-weight ratio, speed of construction, and recyclability. They are commonly used in industrial, commercial, and residential settings, offering a versatile and cost-effective solution for a wide range of construction projects.

-

Custom Machined Length Steel Angle Cutting Services

Metal cutting service refers to the service of providing professional metal material cutting and processing. This service is usually provided by professional metal processing plants or processing plants. Metal cutting can be done by a variety of methods, including laser cutting, plasma cutting, water cutting, etc. These methods can be selected according to different metal materials and processing requirements to ensure the accuracy and quality of cutting. Metal cutting services can usually meet customers’ needs for various metal parts, including cutting and processing of materials such as steel, aluminum alloy, and stainless steel. Customers can entrust metal cutting service providers to process according to their own design drawings or requirements to obtain metal parts that meet their needs.

-

Low Price 10.5mm Thickness Steel Sheet Pile Type 2 Sy295 Cold Z Rolled Sheet Piles

Steel sheet piles are long structural sections with interlocking connections. They are commonly used as retaining walls in waterfront structures, cofferdams, and other applications requiring a barrier against soil or water. These piles are typically made of steel for its strength and durability. The interlocking design allows for a continuous wall to be created, providing efficient support for excavations and other structural needs.

Steel sheet piles are often installed using vibratory hammers, driving the sections into the ground to form a tight barrier. They are available in various shapes and sizes to suit different project requirements. The design and installation of steel sheet piles require expertise to ensure the stability and performance of the structure.

Overall, steel sheet piles are a versatile and effective solution for various construction and civil engineering projects that involve retaining walls, cofferdams, and similar applications.

-

High Quality Sheet Metal Punching Processing Steel Plate Punching / H Beam Punching

Metal punching service refers to the punching processing service for metal materials provided by professional processing plants or service providers. This service usually involves the use of equipment such as drilling machines, punching machines, laser punching, etc., so as to perform precise hole processing on metal materials according to customer requirements.

Metal punching service can be applied to various metal materials, including steel, aluminum alloy, stainless steel, etc. This service is usually used in manufacturing industries such as automobile manufacturing, aerospace, building structures, etc. Customers can entrust professional metal punching service providers to process according to their own design requirements to obtain metal parts that meet their needs.