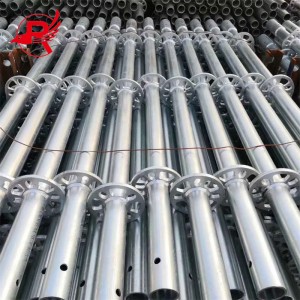

Heavy Duty Q345 Hot Dip Galvanized Ringlock Scaffolding System Modular Peri Layher Compatible Metal Scaffolding

Product detailed parameters

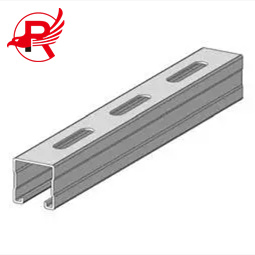

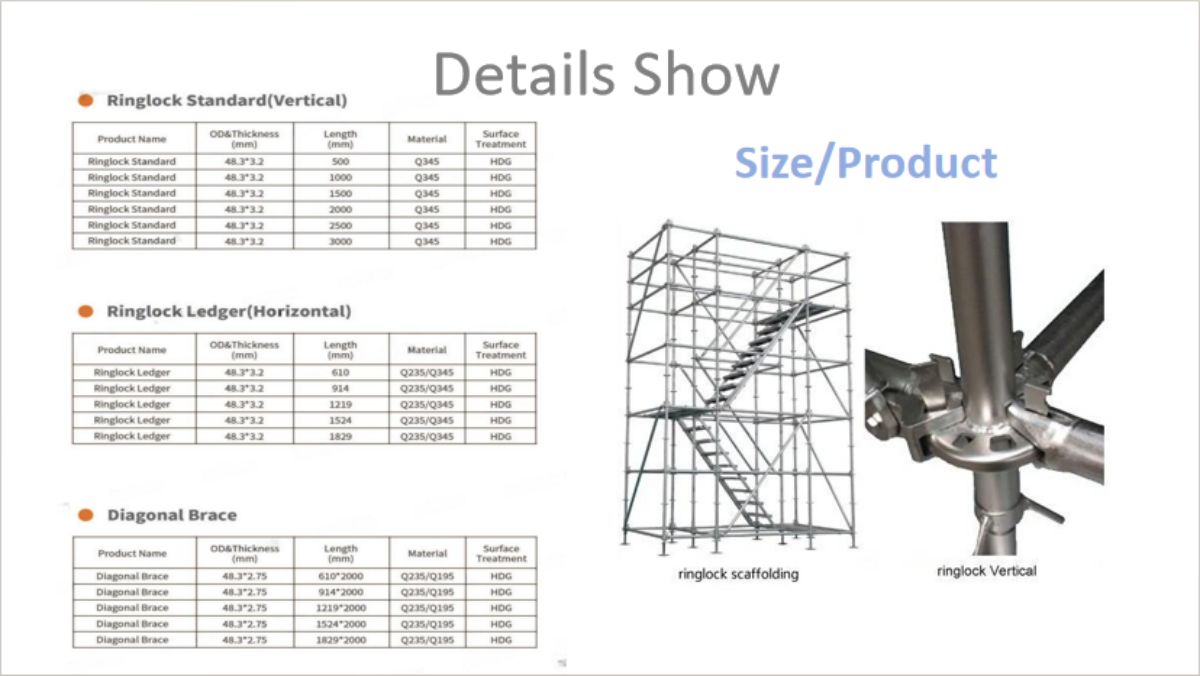

The detail of a Strut Channel includes the following specifications:

| Component | OD & Thickness (mm) | Length | Other Features | Material |

|---|---|---|---|---|

| Ringlock Standard | 48.3 × 3.2 | Unlimited or per customer request | Custom sizes and designs; corrosion protection optional | Q345 |

| Ringlock Ledger | 48.3 × 3.2 | Unlimited or per customer request | Custom sizes and designs; corrosion protection optional | Q235 / Q345 |

| Diagonal Brace | 48.3 × 2.75 | Unlimited or per customer request | Custom sizes and designs; corrosion protection optional | Q235 / Q195 |

| Inspection Standard | – | – | Product manufactured according to national standard | GB Standard |

| Specification | Details |

|---|---|

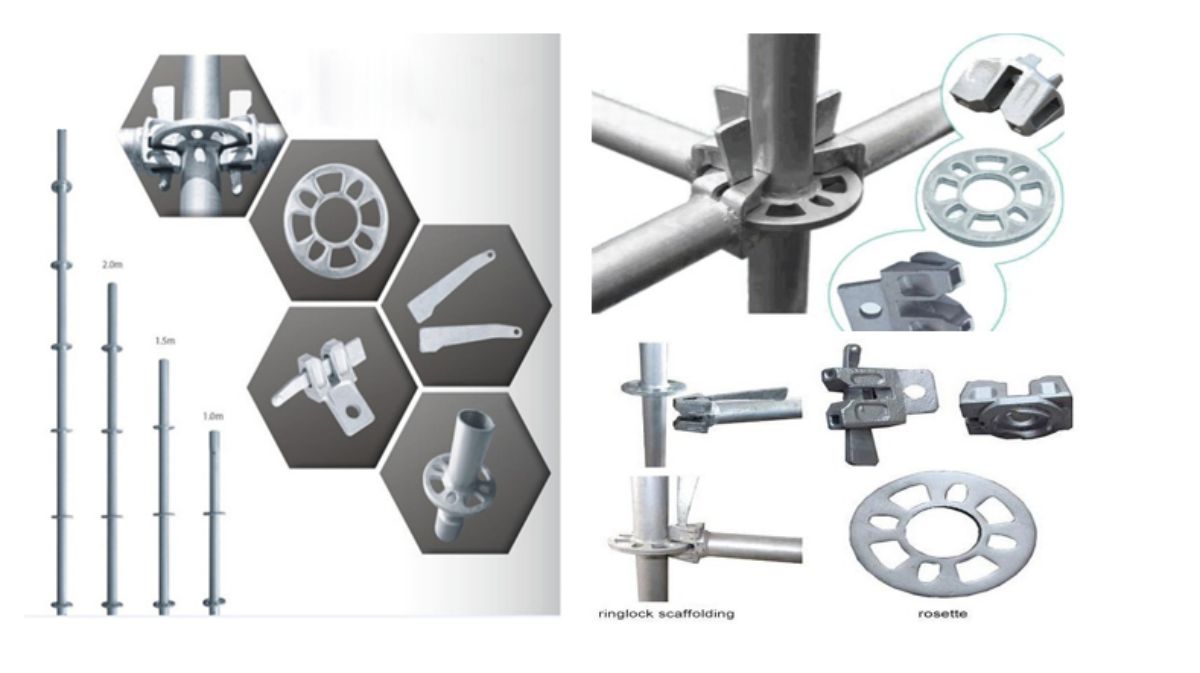

| Size | 48.3 × 3.2 × 3000 mm; Wall thickness: 3.2 mm or 2.75 mm |

| Type | Disc scaffolding |

| Standard | GB (National Standard) |

| Material | Q345 / Q235 / Q195 |

| Factory Location | Tianjin, China |

| Usage | - Building steel structures - Interior decoration |

| Coating | - Galvanized - Galvalume - Hot-dip galvanized |

| Manufacturing Technique | Hot rolled |

| Inspection | Client inspection or third-party inspection |

| Delivery | Container or bulk vessel |

| Quality Assurance | - No damage or bending - Oiled and marked for free - Third-party inspection available before shipment |

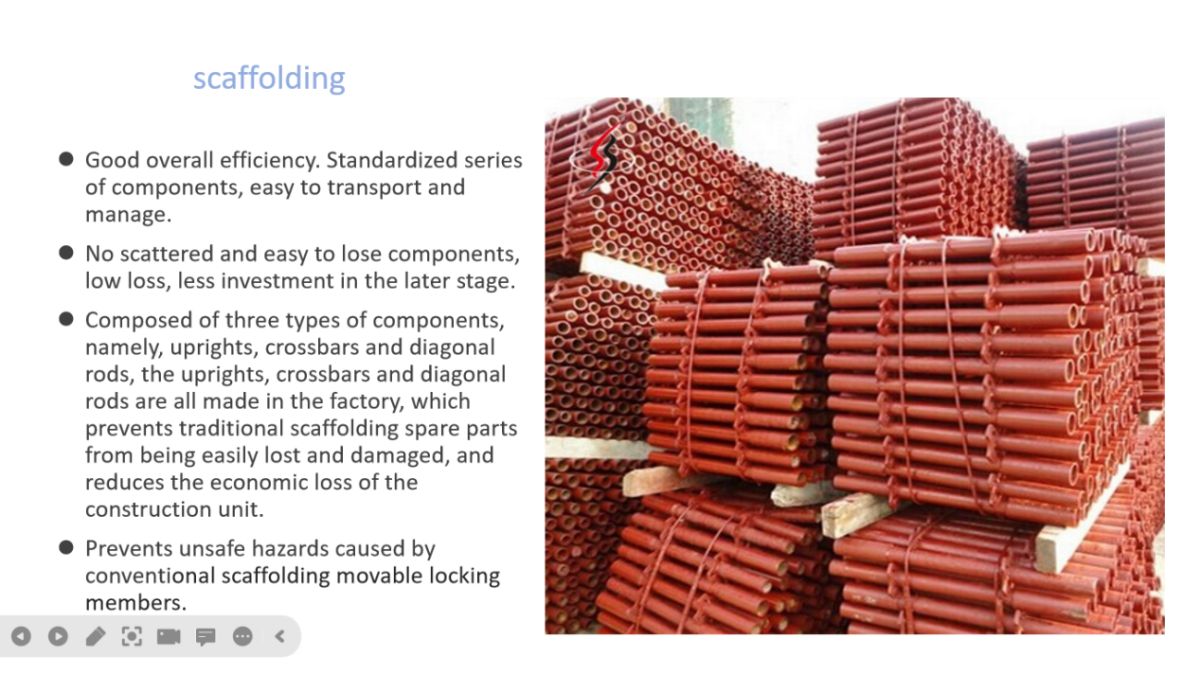

Features

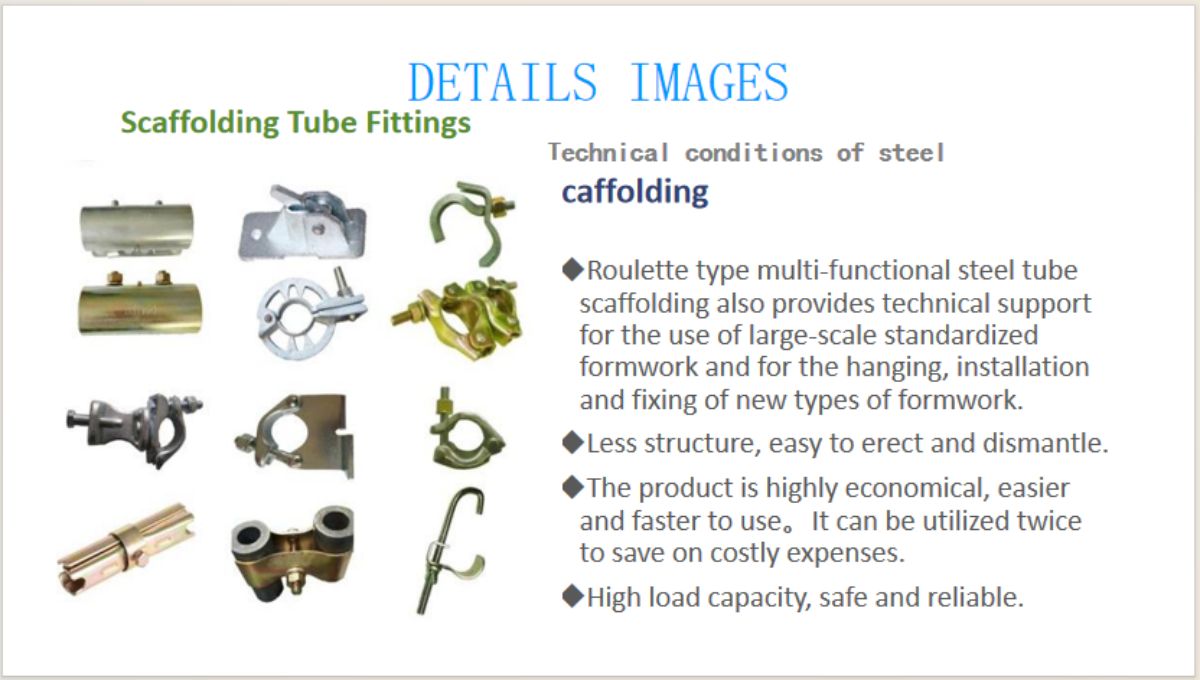

Increased Site Safety & Convenience: Simple to use, easy to move around on job sites. The vertical rods are connected with aligned sockets, so the nodes are arranged in the frame plane, and the joints are not only subjected to bending but also to shear and torque, which results in a stable frame with high bearing capacity.

Functional Use: Can be used as single and double row scaffolding, support ring and pillar to customized building your needs in the field of construction work with different dimensions, shapes and load bearing capacity.

Fast & Convenient: Bolt rather than nut fastening ensuring a faster assembly / dismantle, no bolts lost or scattered fasteners. The Erecta-Scaffold System assembles over five times faster than traditional scaffolding, and is safer to assemble and use.

Cost Effective: The modular components can be easily transported, stored and handled. Minimum Loose parts cost, less losses, minimum Investment, and can be recycled.

Sturdy: The hot dip galvanized finish is rust resistant and ensures stand grids a long lasting service life.

Application

Use of Mobile Scaffolding: It is more applicable for indoor decoration, outdoor wall construction, building scaffolds (inside & outside), cast in beams, formwork support, bridges, tunnels, stage arrangement, and full tower system.

Competitive Industries: Mainly used in oil & gas, water & wastewater, transportation, infrastructure and maritime engineering projects.

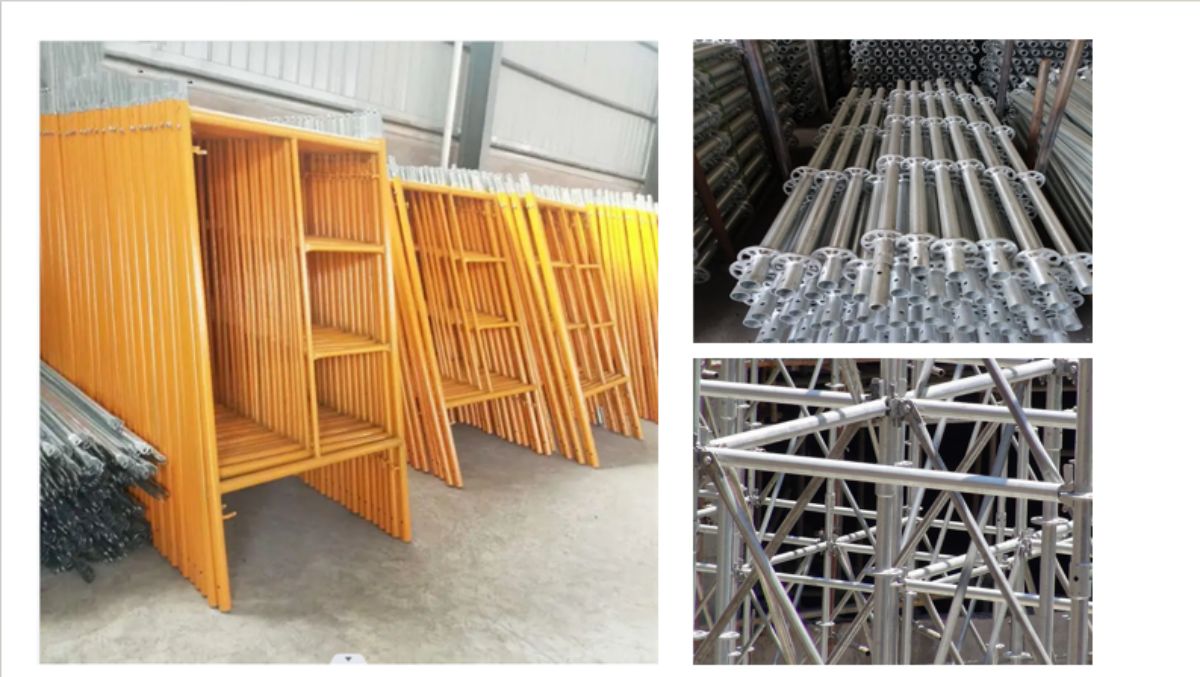

Packaging & Shipping

Customer visits

FAQ

What is the lead time of orders?

A: Delivery schedules are mainly dependent on order quantity. Normally we ship within 10-15 working days after payment confirmation.

What surface treatment can you provide?

A: We have a full range of finishes such as Electro-galvanized, Yellow Zinc Plated, Black Oxide and Hot-Dip Galvanized(HDG) and more customized coatings.

What materials do you work with?

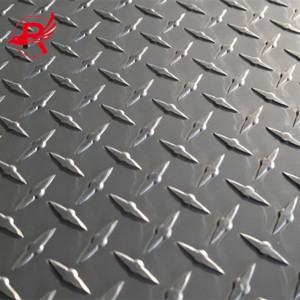

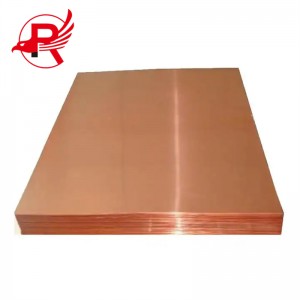

A: We deliver high-quality manufactured goods of Carbon Steel, Stainless Steel, Copper, Brass, Aluminum and multiple alloy steels to cater to diverse industrial requirements.

Do you have product samples?

A: Yes, we do have free sample for quality checking. Please get in touch with our team to discuss the logistics.

Where are you shipping from?

A: Tianjin and Shanghai are our main loading ports,there are flexible and convenient shipping schedules to all over the world.

What are your Terms of payment?

A: Our policy is 30% T/T deposit in advance and 70% balance paid against copy of Bill of Lading (B/L).