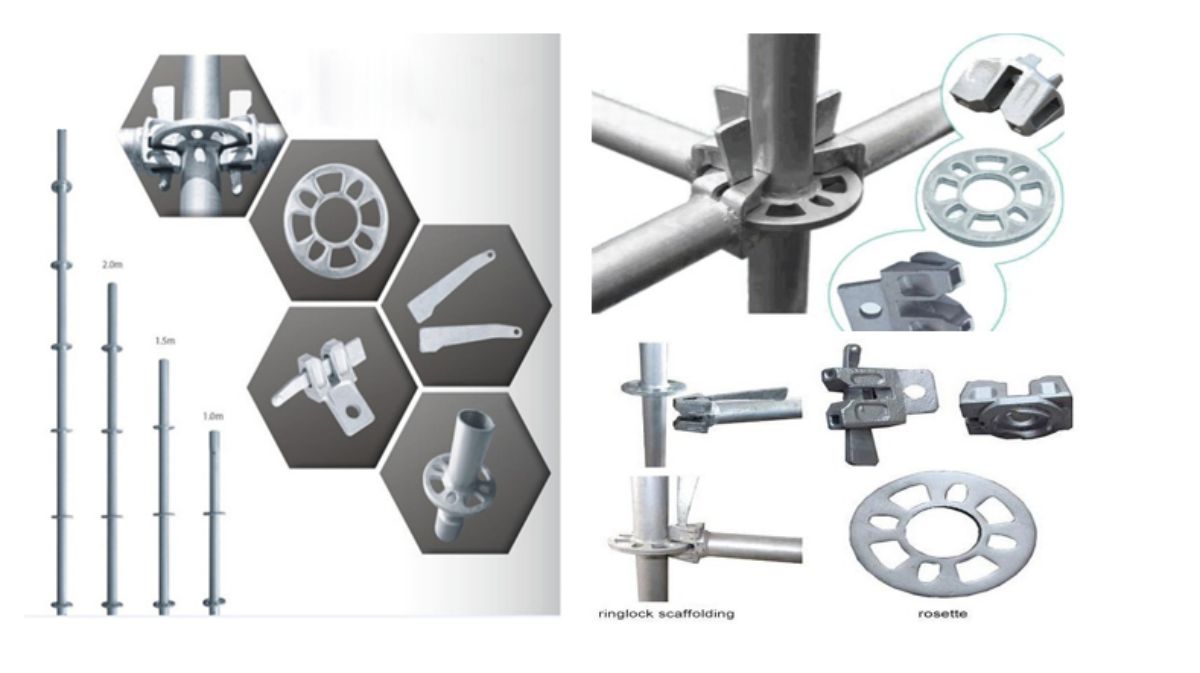

Professional Metal Scaffolding for Construction Andamios Ringlock Scaffolding Peri Layher Construction Scaffolding

Product detailed parameters

Strut Channel – Product Details

| Type | OD × Thickness (mm) | Length | Material | Notes |

|---|---|---|---|---|

| Ringlock Standard | 48.3 × 3.2 | Unlimited or per customer request | Q345 | Custom sizes, corrosion protection available |

| Ringlock Ledger | 48.3 × 3.2 | Unlimited or per customer request | Q235 / Q345 | Custom sizes, corrosion protection available |

| Diagonal Brace | 48.3 × 2.75 | Unlimited or per customer request | Q235 / Q195 | Custom sizes, corrosion protection available |

| Parameter | Details |

|---|---|

| Size | 48.3 × 3.2 × 3000 mm (wall thickness 2.75–3.2 mm) |

| Type | Disc scaffolding |

| Standard | GB |

| Material | Q345, Q235, Q195 |

| Factory Location | Tianjin, China |

| Usage | Building steel structures, interior decoration |

| Coating | Galvanized, Galvalume, Hot-dip galvanized |

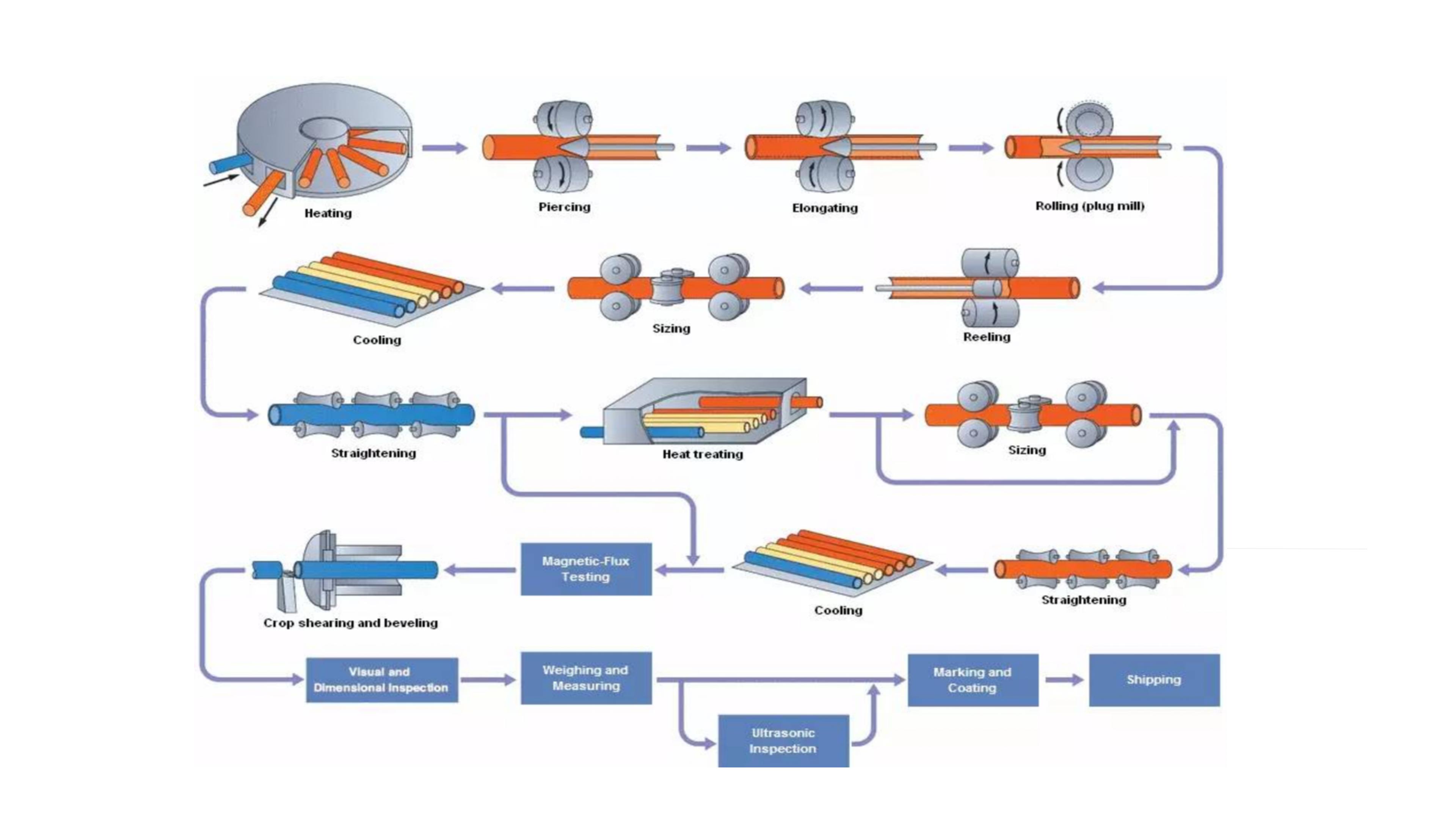

| Technique | Hot-rolled |

| Inspection | Client or third-party inspection |

| Delivery | Container or bulk vessel |

| Quality Features | No damage, no bending; oiled & marked; third-party inspection available |

Features

-

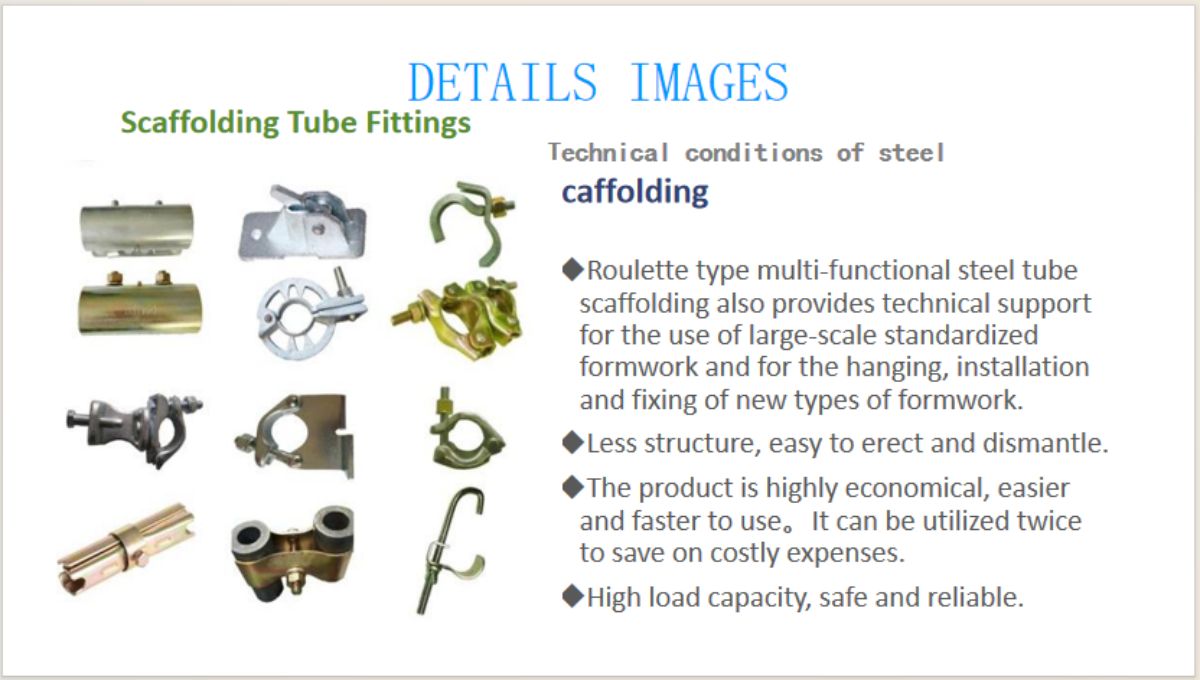

1.Safe and convenient: Facilitates on-site handling and transport; vertical poles use coaxial sockets, providing strong resistance to bending, shear, and torsion for a stable, high-load structure.

-

2.Versatile: Can be configured into single or double-row scaffolds, support frames, and columns of various sizes and load capacities to meet different construction needs.

-

3.Quick assembly: Simple design allows fast installation and disassembly without bolts, over five times faster than conventional scaffolding, reducing safety risks.

-

4.Economical: Standardized components are easy to transport and manage, minimizing losses and future costs; fully recyclable.

-

5.Durable: Hot-dip galvanized surface resists corrosion and rust, ensuring long service life.

Application

Mobile scaffolding is applicable for indoor decoration, external wall engineering, building construction, beam pouring, formwork support, bridges, tunnels, stage laying and full-tower support frame. It can be used in petrochemical, water conservancy, hydropower, transportation, civil construction, and marine engineering and other fields.

Packaging & Shipping

Customer visits

FAQ

Q:How long is the delivery?

A: That depends on how much. Generally it is 10-15 working days after payment have been received.

Q:What surface treatment can we do for you?

A: Galvanized, yellow zinc plated, black coated, HDG and so on.

Q:Which materials do you have?

A:steel, stainless steel, carbon steel, brass, and aluminum.

Q:Can I get a sample?

A: Yes, we do provide free sample to you.

Q:What ports do you ship out from?

A:Tianjin and Shanghai.

Q:Terms of payment?

A: 30% T/T in advance, 70% against B/L copy.