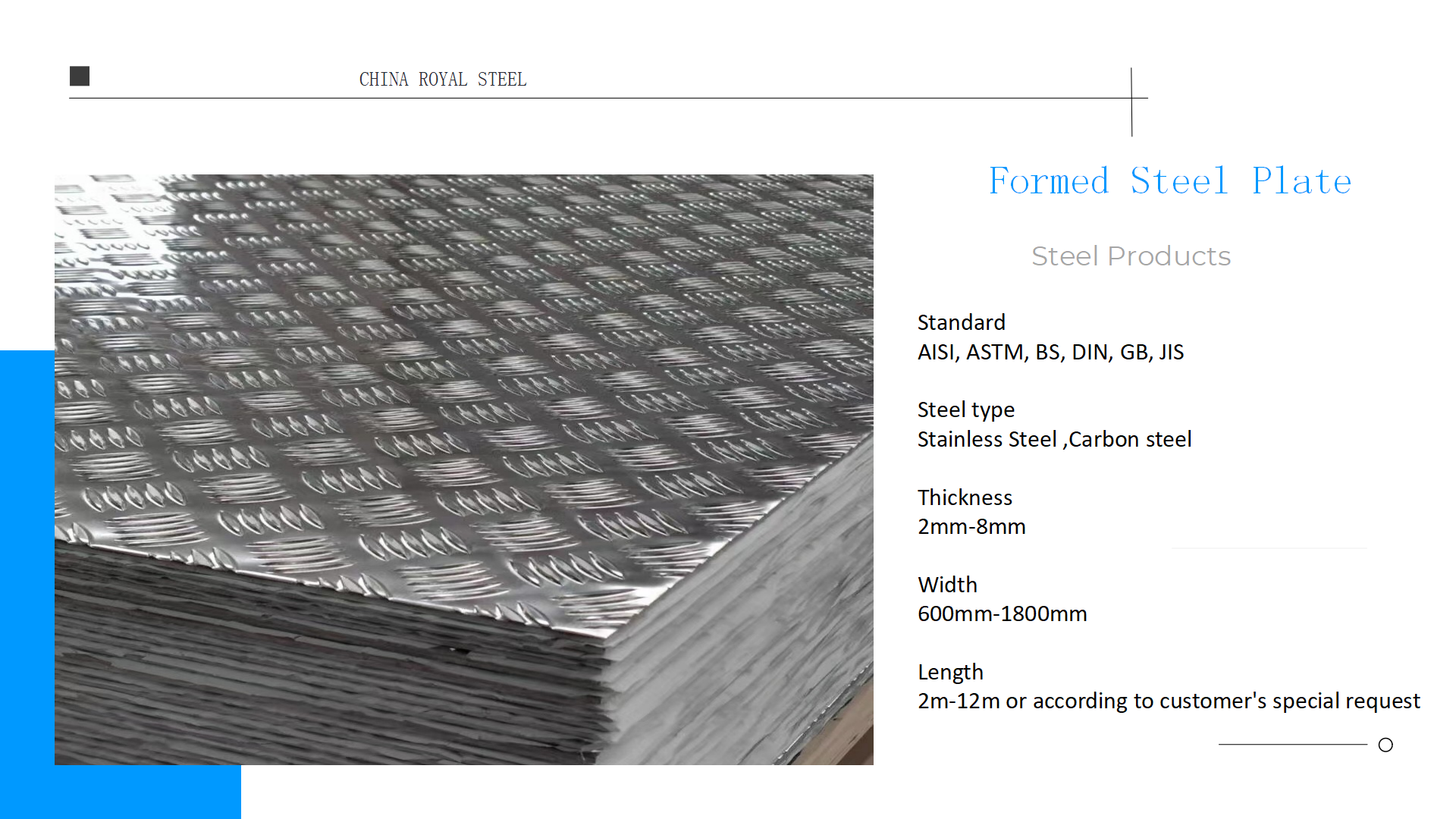

Q235 Q345 A36 Embossed Hot Rolled Carbon Steel Plate Checkered Iron Steel Sheet

Product Detail

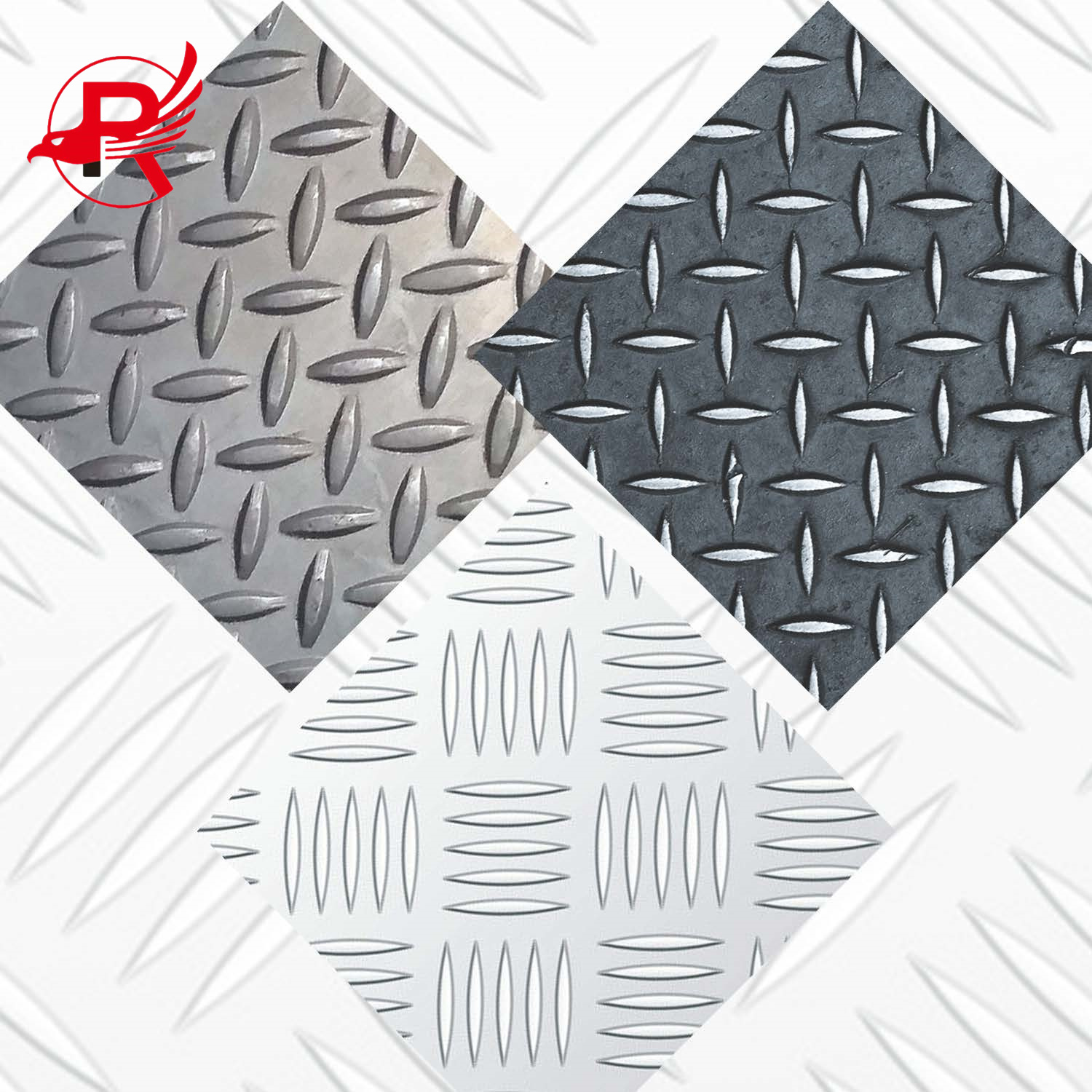

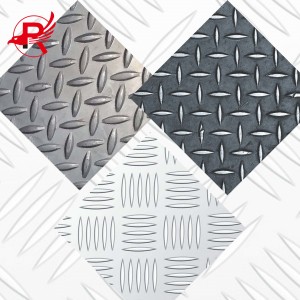

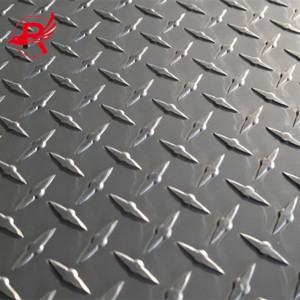

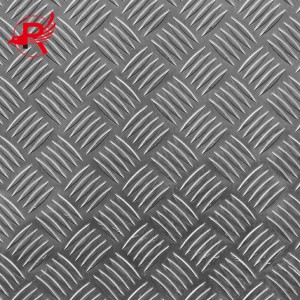

Diamond plate, also known as checkered plate or tread plate, is a type of steel sheet with a raised, patterned surface. These raised patterns provide a non-slip surface, making diamond plate ideal for applications where safety and traction are critical, such as industrial walkways, narrow passages, stairs, and vehicle floors.

Here are some key details about diamond plate:

Material: Diamond plate is typically made of carbon steel or stainless steel, but it can also be made of aluminum or other metals. The material selection depends on the specific application and environmental conditions.

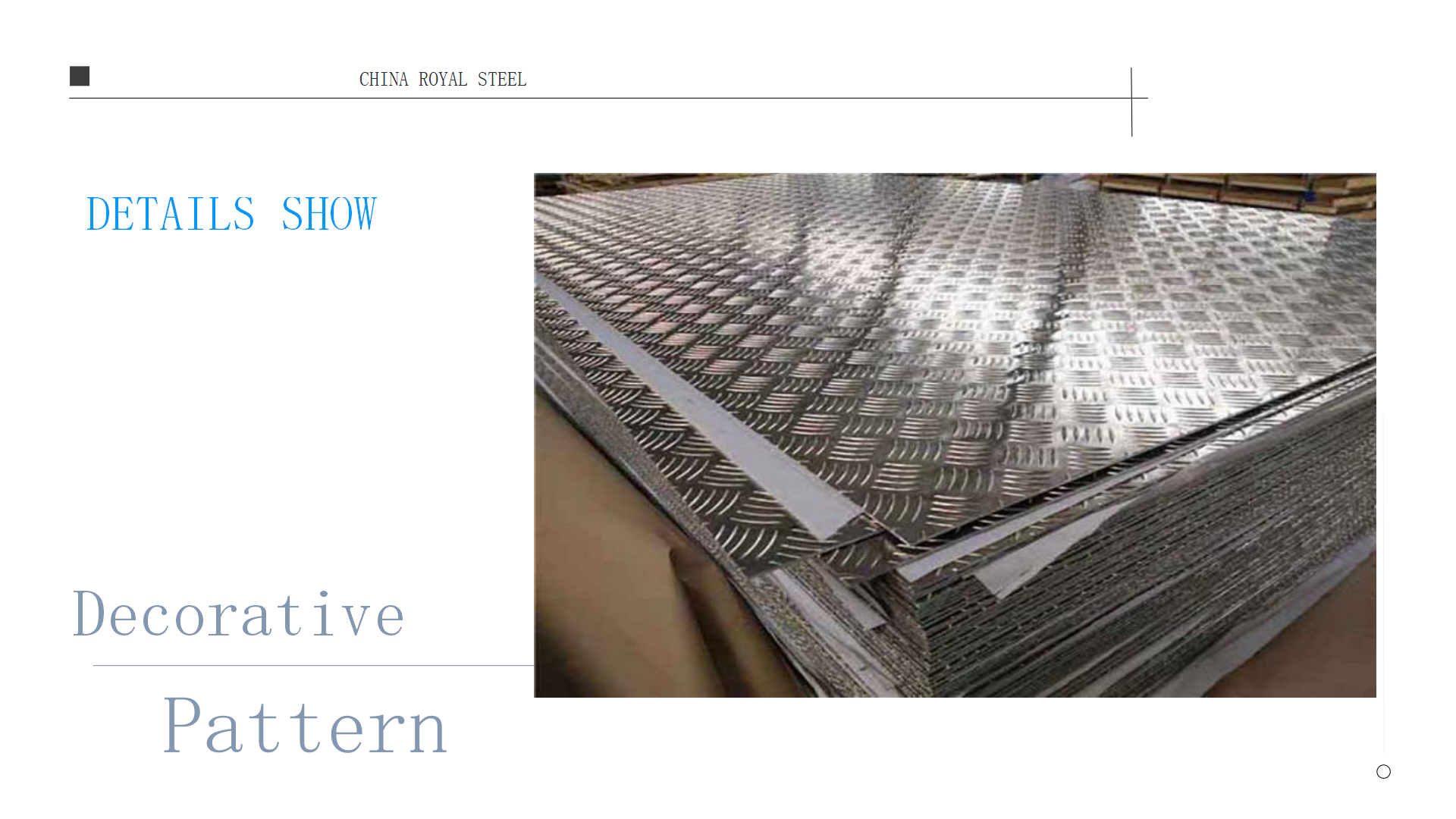

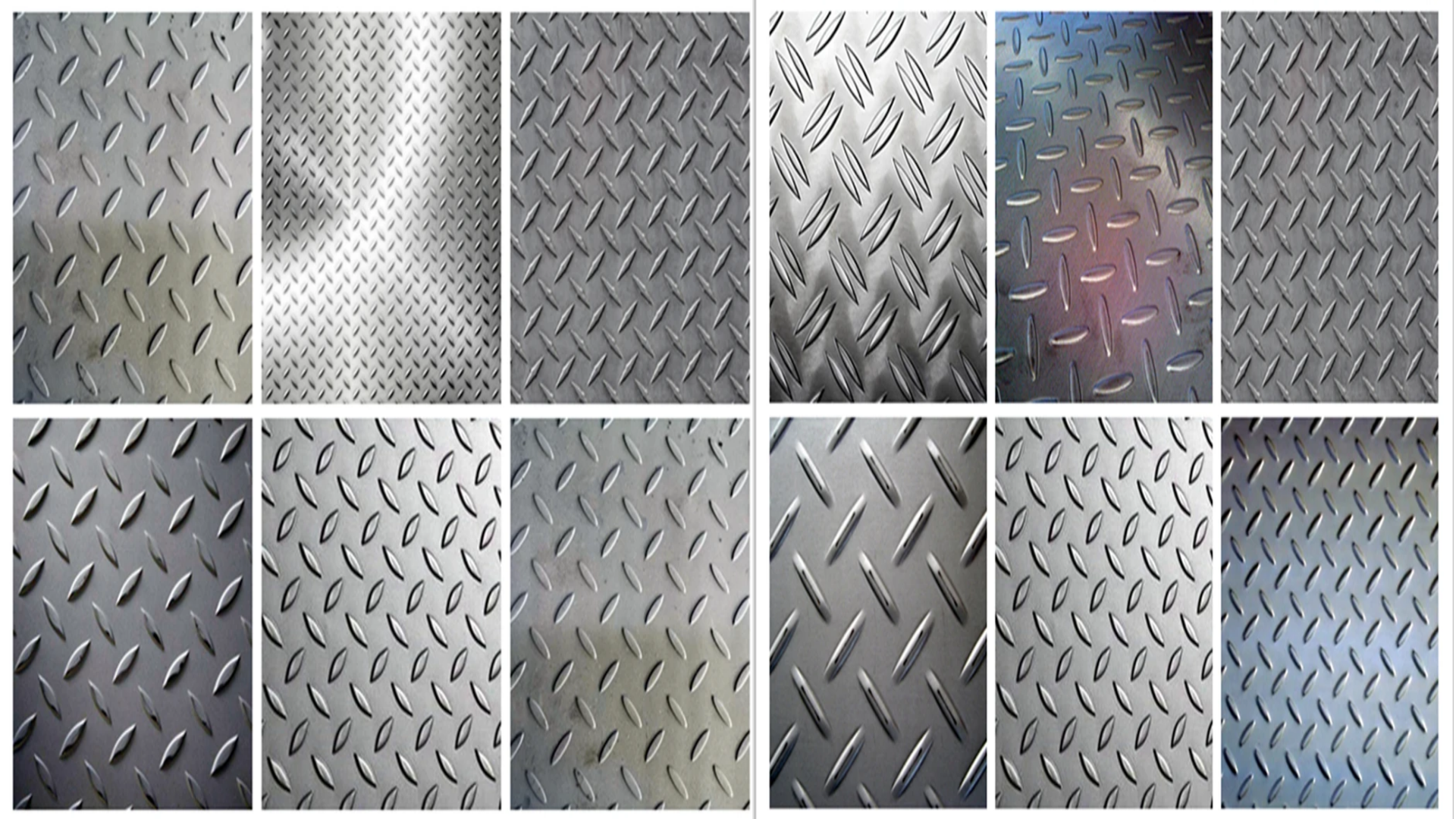

Texture characteristics: The raised texture on the surface of diamond-patterned steel plates typically features a diamond or striped pattern, with varying sizes and spacing. This texture design is intended to enhance grip and stability, thus reducing the risk of slips and falls in industrial environments.

Thickness and Size: Diamond plate comes in various thicknesses and standard sizes, with common thicknesses ranging from 2 mm to 12 mm. Standard sheet sizes vary by manufacturer and intended use, but common sizes include 4 ft x 8 ft, 4 ft x 10 ft, and 5 ft x 10 ft.

Surface Finish: Diamond plate can have various surface finishes, including smooth, painted, or galvanized. Each finish offers advantages in terms of corrosion resistance, aesthetics, and durability.

Application Scope: Diamond-patterned steel plates are widely used in industrial and commercial applications, such as factories, construction sites, transportation vehicles, and ships. Their non-slip surface significantly enhances safety for personnel and machinery in areas with high foot traffic or heavy machinery operations.

Production and Customization: Diamond-patterned steel plates can be customized to meet specific customer requirements, including size cutting, shape modification, and the addition of features such as edge treatments and mounting holes.

|

Product Name

|

checkered steel plate

|

|

Material

|

Q235B,Q195B,A283 GR.A,A283 GR.C,A285 GR.A,GR.B,GR,C,ST52,ST37,ST35,A36,SS400,SS540,S275JR,

S355JR,S275J2H,Q345,Q345B,A516 GR.50/GR.60,GR.70,etc |

|

Thickness

|

0.1-500mm or as required

|

|

Width

|

100-3500mm or as customized

|

|

Length

|

1000-12000mm or as required

|

|

Surface

|

Galvanized coated or as customer requirements

|

|

Package

|

Waterproof pater, steel strips packed

Standard export package,suit for all kinds of transport,or as required. |

|

Payment terms

|

T/T Western Union etc

|

|

Application

|

Steel plates are widely used in shipbuilding, construction, and machinery manufacturing. The dimensions of alloy steel plates can be customized according to customer requirements. |

|

Delivery time

|

10-15 days after receive the deposit

|

Features

The core advantages of patterned steel plates lie in their practical functionality and adaptability to various scenarios. They address key needs such as safety and load-bearing capacity, while offering flexible application possibilities. These advantages can be summarized in five points:

Strong Anti-Slip Performance, Safety First: The raised diamond, linear, or other patterned surface significantly increases friction, effectively reducing the risk of slips and falls, even in environments with oil, water, or dust (such as factory floors or rainy-day stairs). This makes it a core choice for high-safety-requirement applications.

High Load Capacity and Durability: The base material is typically high-strength steel, such as carbon steel or stainless steel, providing excellent resistance to compression and impact. It can withstand heavy machinery (like forklifts or equipment bases) and prolonged foot traffic, without easily deforming or cracking, resulting in a lifespan far exceeding that of ordinary anti-slip materials.

Strong Environmental Adaptability: The material and surface treatment can be flexibly tailored to the environment—stainless steel is resistant to acids, alkalis, and moisture, suitable for food processing plants and marine decks; galvanized or painted carbon steel offers enhanced rust resistance for outdoor/semi-outdoor environments like platforms and gas stations, resisting harsh conditions.

Easy Processing and Customization: It can be cut, bent, and welded to suit various needs, including non-standard sizes (like custom-shaped stair treads or truck bed linings). Drilling and edge finishing can further adapt it to specific installation requirements, simplifying the process and reducing costs.

Functionality and Aesthetics Combined: Beyond its practical attributes, its unique texture complements industrial and vintage design styles. It can be used as a decorative element in commercial spaces (restaurant floors, studio walls) and residential settings (garage floors, balcony treads), offering a distinctive and robust visual effect without requiring additional decoration—a truly functional and aesthetically pleasing solution.

Application

Packaging & Shipping

The packaging of inspected steel sheets typically includes measures to secure them during transport, ensuring their integrity and preventing damage. The sheets are usually stacked and bound together with steel straps or banding to prevent movement and maintain their shape. Additionally, protective materials such as plastic or cardboard may be used to shield the sheets from scratches and other surface damage. The bundled sheets are then typically placed on pallets for easy handling and transport. Finally, the entire package is usually wrapped with plastic or shrink film for further protection against moisture and weather. These packaging methods are designed to safeguard the inspected steel sheets and ensure their safe arrival at their destination.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.