A Steel Sheet Pile is a prefabricated, interlocking steel section used to create retaining walls, cofferdams, and waterfront structures, providing strong soil retention and water-tight barriers in construction and civil engineering projects.

Hot Rolled 6 / 9 / 12m Length U-Shaped Water-Stop Steel Sheet Pile Wall Factory

PRODUCT PRODUCTION PROCESS

The production process of Q235 steel sheet piles usually includes the following steps:

Raw material preparation: Prepare hot-rolled steel plates as raw materials for the production of U-shaped steel sheet piles.

Hot Rolling: Q235 steel sheet piles are sent to a hot rolling mill for processing, where they undergo pre-bending and rolling to form a U-shaped cross-section.

Cutting: U-shaped steel sheet piles are cut to the desired length using cutting equipment.

Cold Bending: Steel sheet piles are cold-bent to ensure they meet the required size and shape.

Inspection and Quality Control: Finished products are inspected to ensure compliance with relevant standards and specifications.

Packaging and Transportation: Finished products are packaged and transported to the customer or construction site.

These steps may vary according to different production processes and equipment, but are usually the basic steps of the production process of hot-rolled U-shaped steel sheet piles.

|

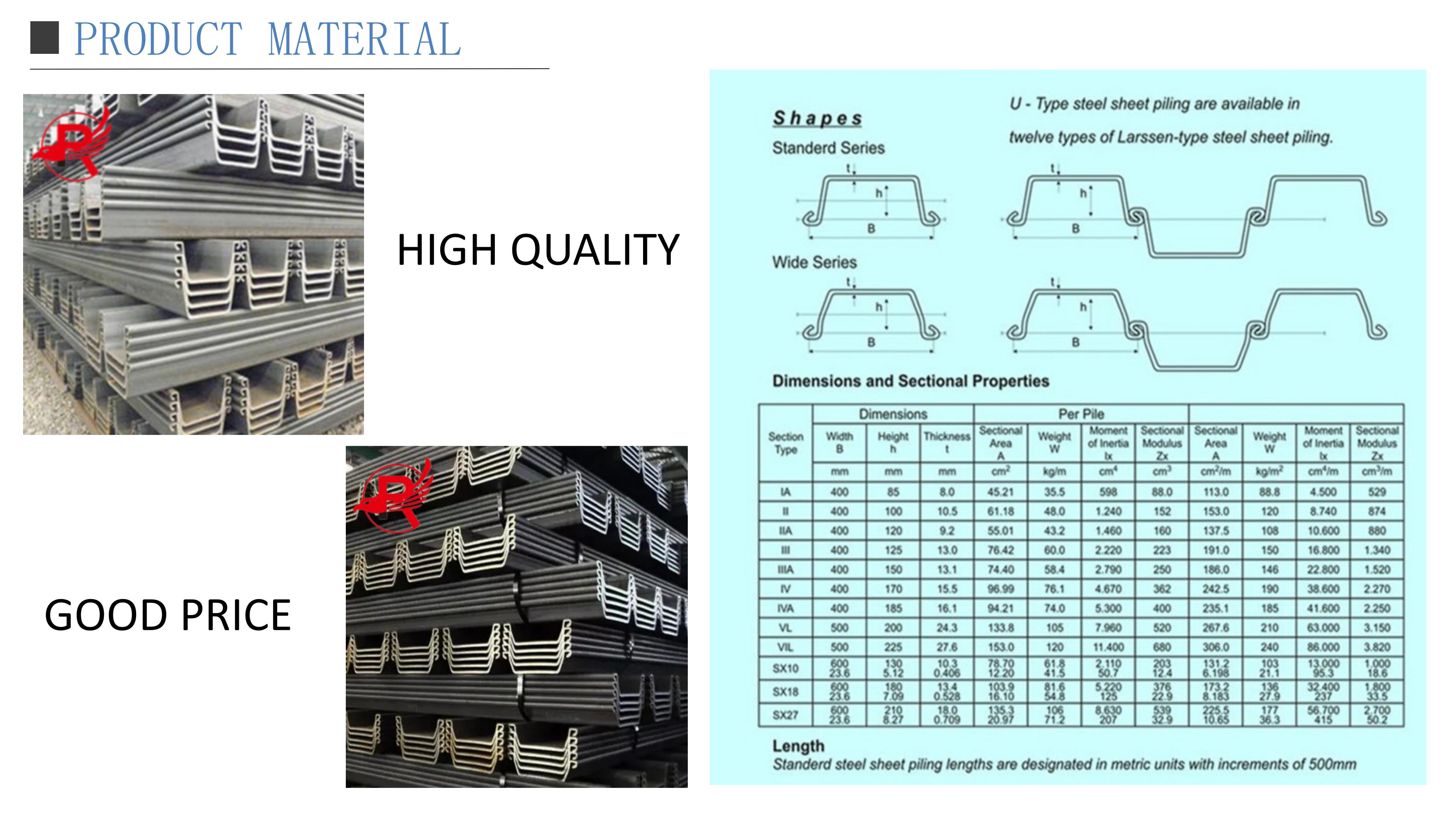

SPECIFICATIONS FOR U SHEET PILE |

|

| 1. Size | 1) 400*100mm,500*200mm,600*360mm |

| 2)Wall Thickness:4—16MM | |

| 3)U type sheet pile | |

| 2. Standard: | GB/T29654-2013 EN10249-1 |

| 3.Material | Q235 Q235B Q345 Q345B S235 S240 S270 S275 SY295 S355 S340 Sy390 Nz14 Au20 Az36 Pz12 Pz18 Pz27 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)rolling stock |

| 2)Building steel structure | |

| 3Cable tray | |

| 6. Coating: | 1) Bared2) Black Painted (varnish coating)3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | U type sheet pile |

| 9. Section Shape: | U |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Free for oiled&marking3) All goods can be checked by third party inspection before shipment |

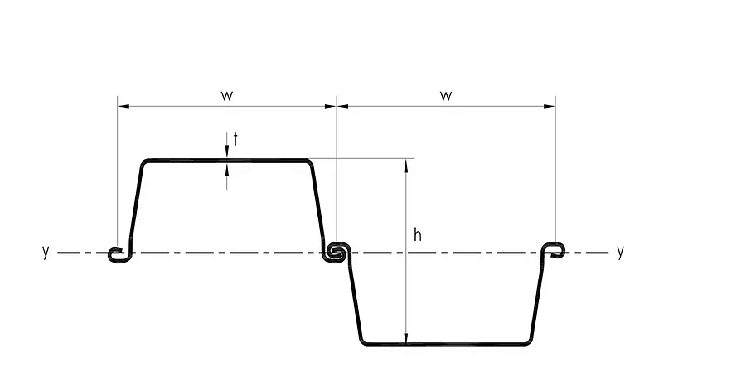

PRODUCT SIZE

*Send the email to [email protected] to get a quotation for your projects

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Others available on request

Length

35.0m maximum but any project specific length can be produced

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

Grip Plate

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

In geological structure environments such as hard soil, shale, and hard pebbles, the hammering and vibration of steel sheet piles are small, the construction is more difficult, and more sophisticated equipment is required for construction.

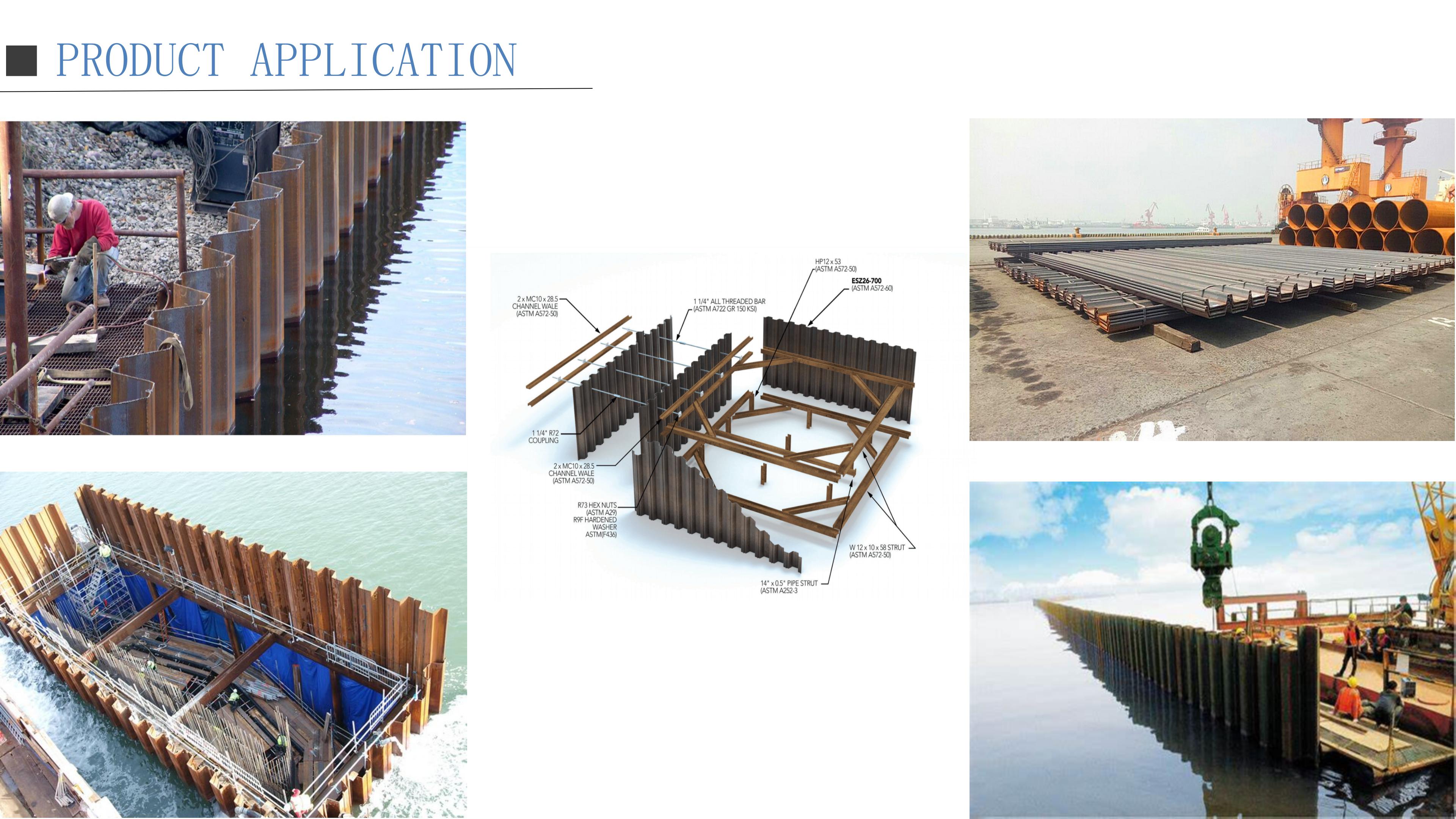

APPLICATION

Metal sheet piling perform better in foundation support in deeper silt layers, humid and underwater environments. The intensity and frequency of hammering and vibration need to be appropriately controlled to ensure construction quality.

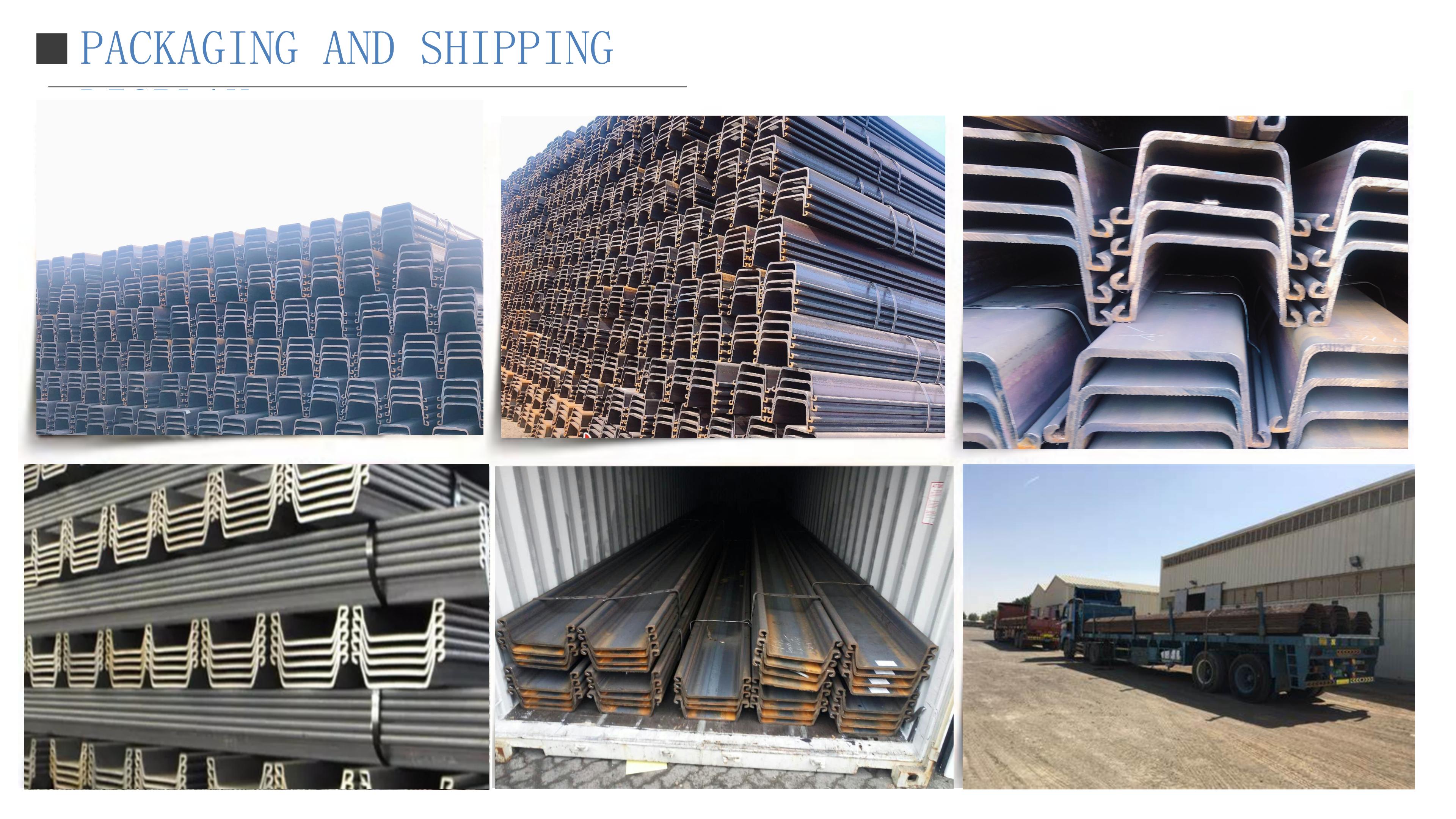

PACKAGING AND SHIPPING

1. Container Transport

Container transport is a common method of transporting steel sheet piles, suitable for smaller sheet piles. Currently, many companies use sea containers for international trade of steel sheet piles. This method of transport is cost-effective and unaffected by weather and road conditions. However, large sheet piles, due to their large size, do not fit within the size limits of containers and are therefore not suitable for container transport.

2. Bulk Transport

Bulk transport involves transporting sheet piles bare on a vehicle without packaging. This approach minimizes transportation costs, but also carries the risk of damage. Reinforcement measures, such as using lashings to secure the sheet piles to the vehicle, are necessary to mitigate this risk, and the vehicle must be able to withstand the load.

3. Flatbed Transport

Flatbed transport involves transporting sheet piles loaded onto a flatbed truck. This method is safer than bulk transport and can accommodate larger sheet piles. However, this method requires the use of different types of flatbed trucks, such as telescopic flatbed trucks and low-bed trucks, depending on the length and weight of the sheet piles.

4. Rail Transportation

Rail transportation involves transporting steel sheet piles installed on specialized railway vehicles. Its advantages are high speed, relatively low cost, and guaranteed transportation safety. However, special attention must be paid to securing the piles and controlling the speed during transportation to minimize damage.

COMPANY STRENGTH

A delicious world, Made in China Excellent Service Advanced Quality The best choice of food

1.The scale effect: The company possesses large-scale supply chain and big steel factory, fulfilling the scale management on transportation and procurement for becoming a comprehensive steel enterprise that takes production, service.

2.The Product Variety: When it comes to product variety, there is all kind of steel retailer you want to buy from us for dealing in steel structure, steel rail, steel sheet pile, photovoltaic bracket channel steel, silicon steel coil and many more products, so that can more flexible help you find out the right one.

3.Stable supply: More stable production line and supply chain could offer you more stable supply. And that’s crucial for buyers who need a lot of steel.

4.Brand impact: Have higher brand influence and larger market.

5.Service: Big company with customisation, transport and production all in.

6.Price competitiveness: reasonable price

If you want to know more about steel sheet piles, you can feel free to contact me.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

When a customer wishes to visit a product, the following steps are typically arranged:

Schedule a visit: Customers can contact the manufacturer or sales representative in advance to schedule a time and location for a product visit.

Arrange a guided tour: A professional or sales representative will serve as a guide to explain the product's production process, process technology, and quality control procedures.

Product Display: During the tour, customers will be shown products at various stages of production to help them understand the production process and quality standards.

Answering questions: During the tour, customers may have various questions. The tour guide or sales representative should patiently answer them and provide relevant technical and quality information.

Providing samples: If possible, provide product samples to help customers gain a more intuitive understanding of the product's quality and features.

Follow-up: After the tour, follow up promptly with customer feedback and needs, providing further support and services.

FAQ

Q1: What kind of products do you have?

A1: We are the professional manufacturer of Steel Sheet Piles, Rail, Silicon Steel, Shaped Steel and other Steel products.

Q2: How long is your delivery time?

A2: Delivery is 5–10 days for goods in stock. For out of stock products, delivery time is 15 to 20 days by the quantity of order.

Q3: How to your company do superior?

A3: We have professional team and advanced production lines to ensure high quality products and efficient service.

Q4: Are you a trade company or manufacturer?

A4: We are a factory with direct manufacturing capacities.

Q5: What are your terms of payment?

A5: For orders≤1000 USD, full payment must be paid in advance. 30% T/T in advance for orders≥$1,000, balance before shipment.

For any other inquiries, please feel free to contact us via the methods below.