Railroad Guide Rail Light/Grooved Rail/Heavy Rail/ISCOR Steel Rail Price Best Quality Rails

Industrial Train Rail Steel generally consist of upper and lower rail heads and side plates. The rail heads and side plates are straight components and have a certain strength and hardness to withstand various mechanical pressures and weights. At the same time, the wear resistance and corrosion resistance of the material must also be considered when manufacturing industrial rails to ensure their service life and quality.

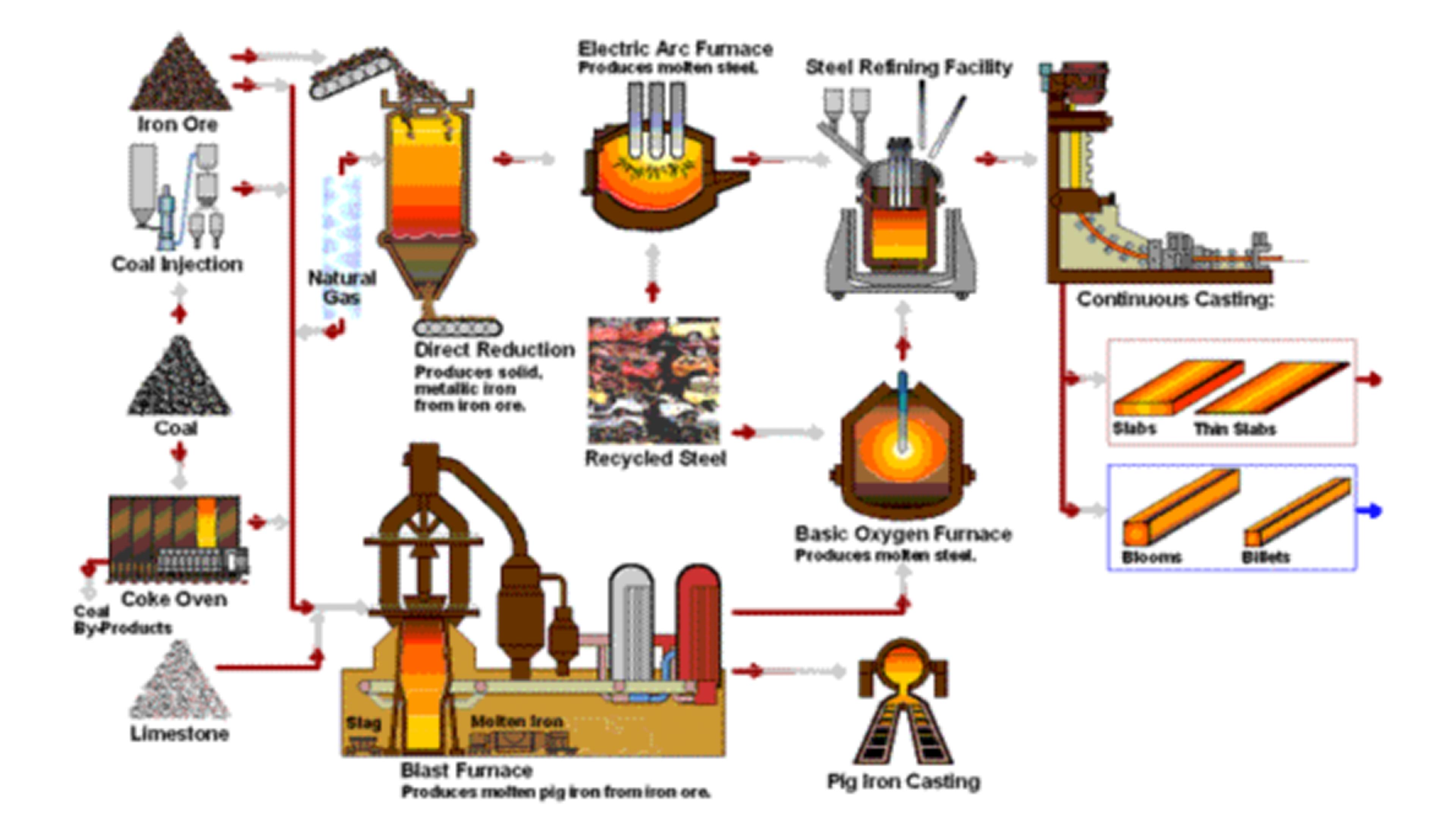

PRODUCT PRODUCTION PROCESS

Technology and Construction Process

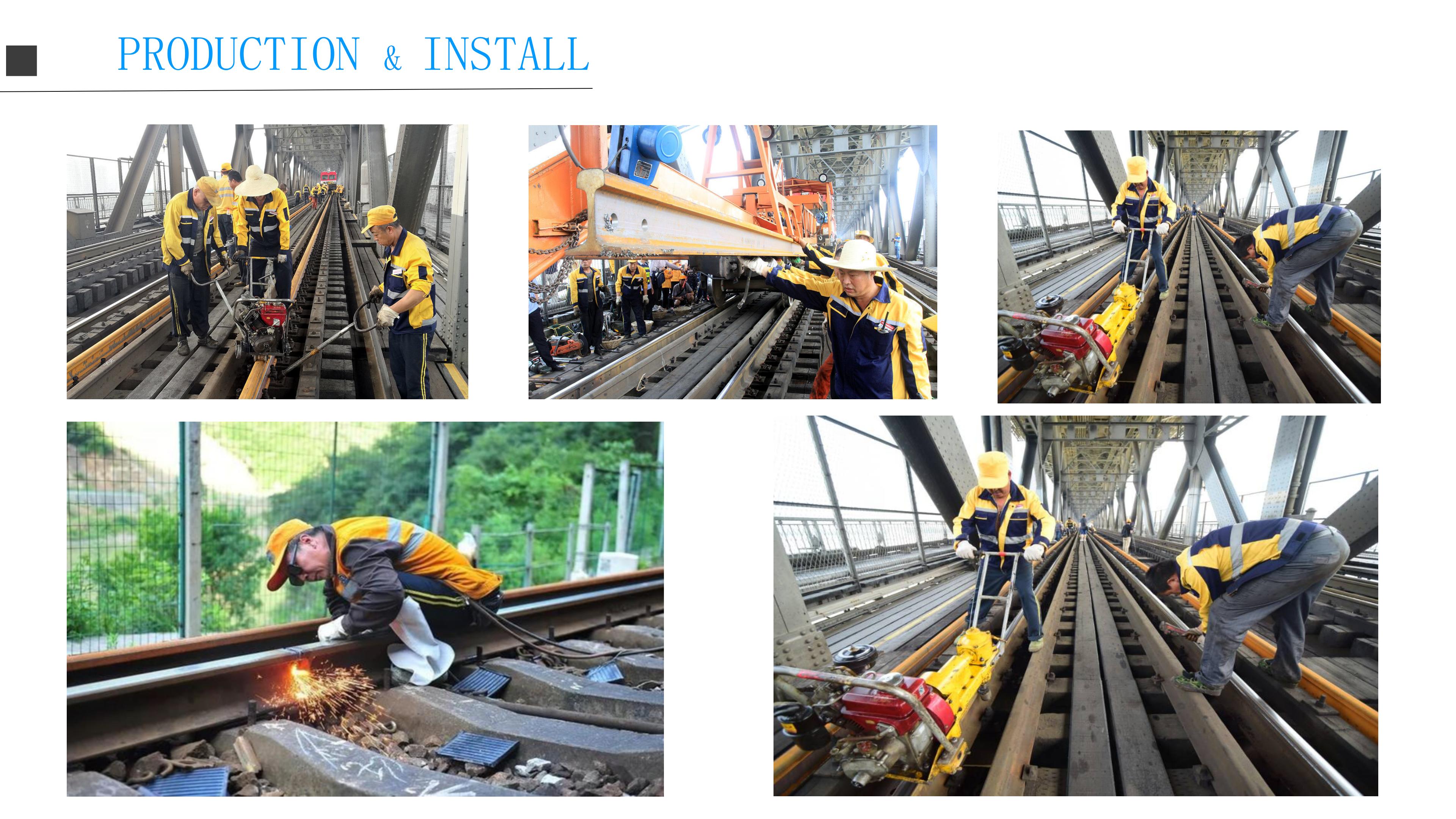

The process of constructing The Railroad Track tracks involves precision engineering and careful consideration of various factors. It begins with designing the track layout, taking into account the intended usage, train speeds, and terrain. Once the design is finalized, the construction process commences with the following key steps:

1. Excavation and Foundation: Construction teams prepare the ground by excavating and building a solid foundation to support the weight and pressure of the trains.

2. Ballast Installation: A layer of crushed stone, called ballast, is laid on the prepared ground. This layer of crushed stone acts as a shock absorber, provides stability, and helps evenly distribute the load.

3. Sleepers and Fixing: Wooden or concrete sleepers are then installed on top of the ballast to simulate a frame structure. These sleepers provide a solid foundation for the rails. They are secured using specialized spikes or clips to ensure they remain firmly in place.

4. Track Installation: 10-meter-long steel rails (commonly known as standard gauge) are meticulously laid on the sleepers. These rails are made of high-quality steel for exceptional strength and durability.

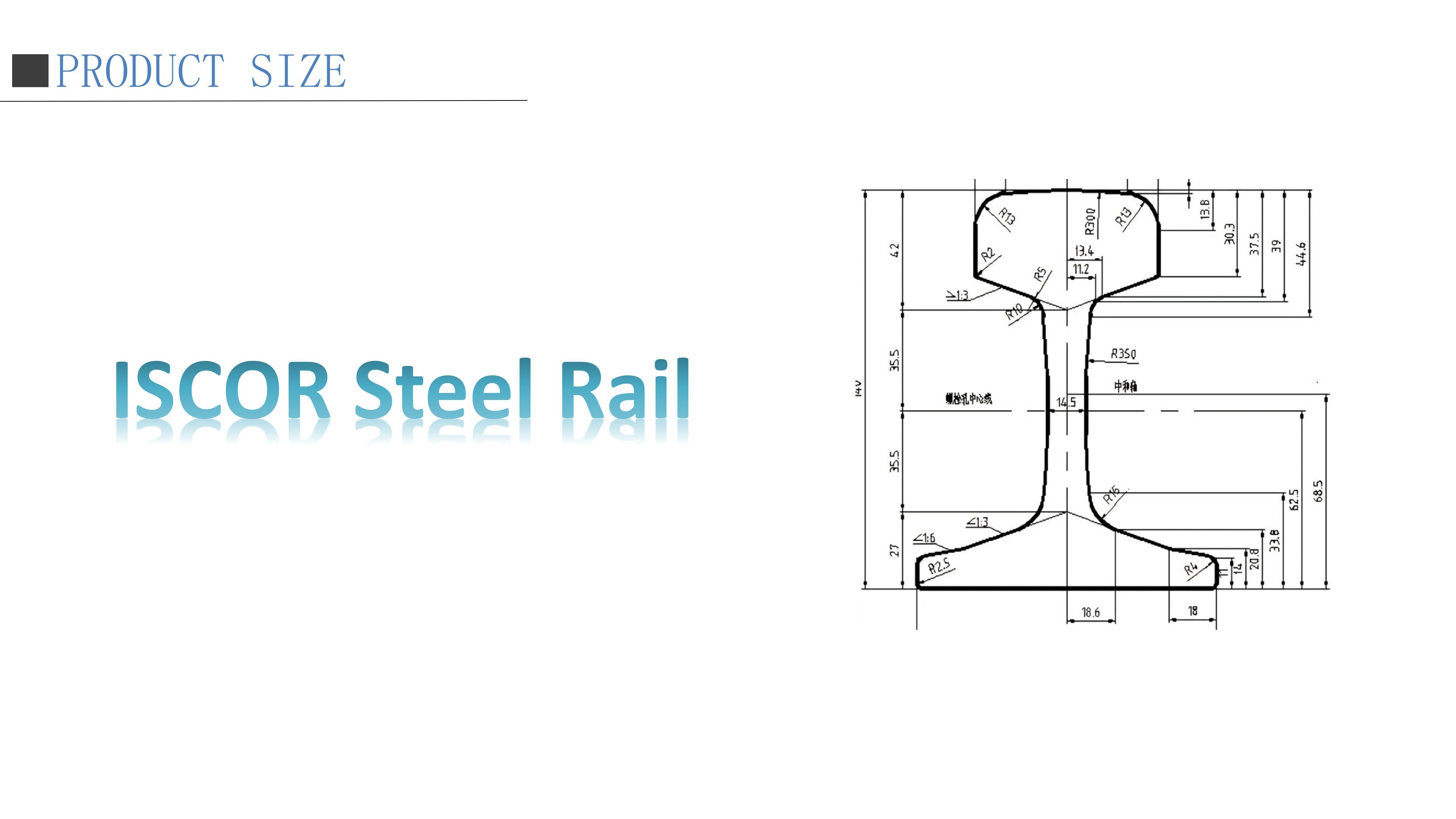

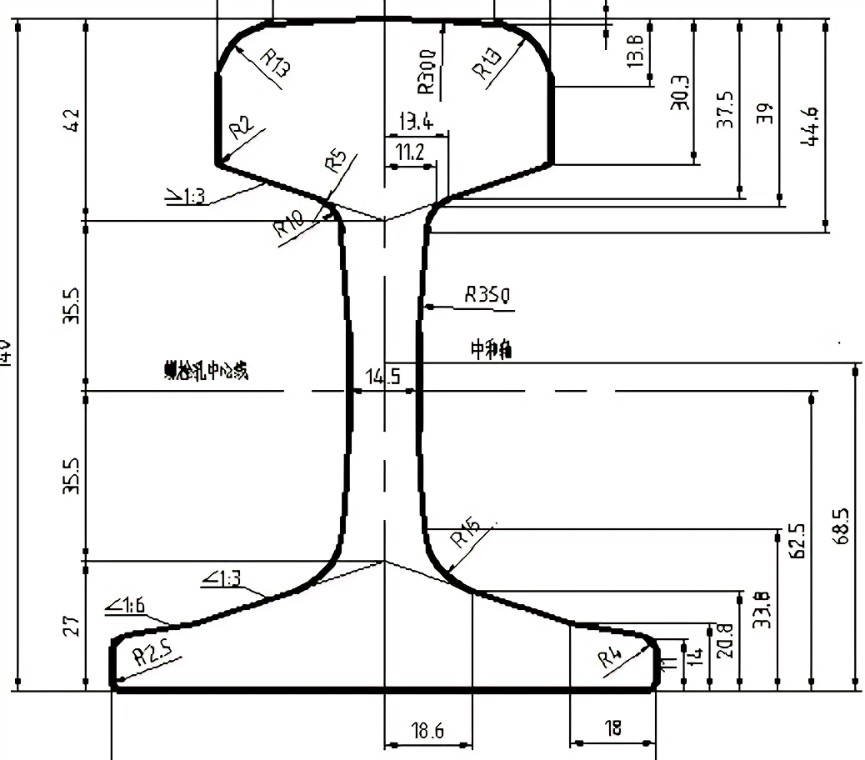

PRODUCT SIZE

| The ISCOR standard steel rail | |||||||

| model | size (mm) | substance | material quality | length | |||

| head breadth | altitude | baseboard | waist depth | (kg/m) | (m) | ||

| A(mm | B(mm) | C(mm) | D(mm) | ||||

| 15KG | 41.28 | 76.2 | 76.2 | 7.54 | 14.905 | 700 | 9 |

| 22KG | 50.01 | 95.25 | 95.25 | 9.92 | 22.542 | 700 | 9 |

| 30KG | 57.15 | 109.54 | 109.54 | 11.5 | 30.25 | 900A | 9 |

| 40KG | 63.5 | 127 | 127 | 14 | 40.31 | 900A | 9-25 |

| 48KG | 68 | 150 | 127 | 14 | 47.6 | 900A | 9-25 |

| 57KG | 71.2 | 165 | 140 | 16 | 57.4 | 900A | 9-25 |

ISCOR steel rail:

Specifications: 15kg, 22kg, 30kg, 40kg, 48kg, 57kg

Standard: ISCOR

Length: 9-25m

ADVANTAGE

1.1 High strength

The material of the steel railway is high-quality steel, which has high strength and toughness. Under extreme conditions such as heavy loads and long-term driving of trains, it can withstand great pressure and deformation, ensuring the safety and stability of railway transportation.

1.2 Good Wear Resistance

The track's surface hardness is high, effectively resisting wheel wear. Furthermore, track specifications and technology have been refined over the years, reducing wear on certain components and extending their service life.

1.3 Easy Maintenance

The track's overall design is highly stable, making maintenance relatively easy and significantly minimizing disruption and damage to the railway line.

PROJECT

Our company’s 13,800 tons of Steel Railroad Track exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: [email protected]

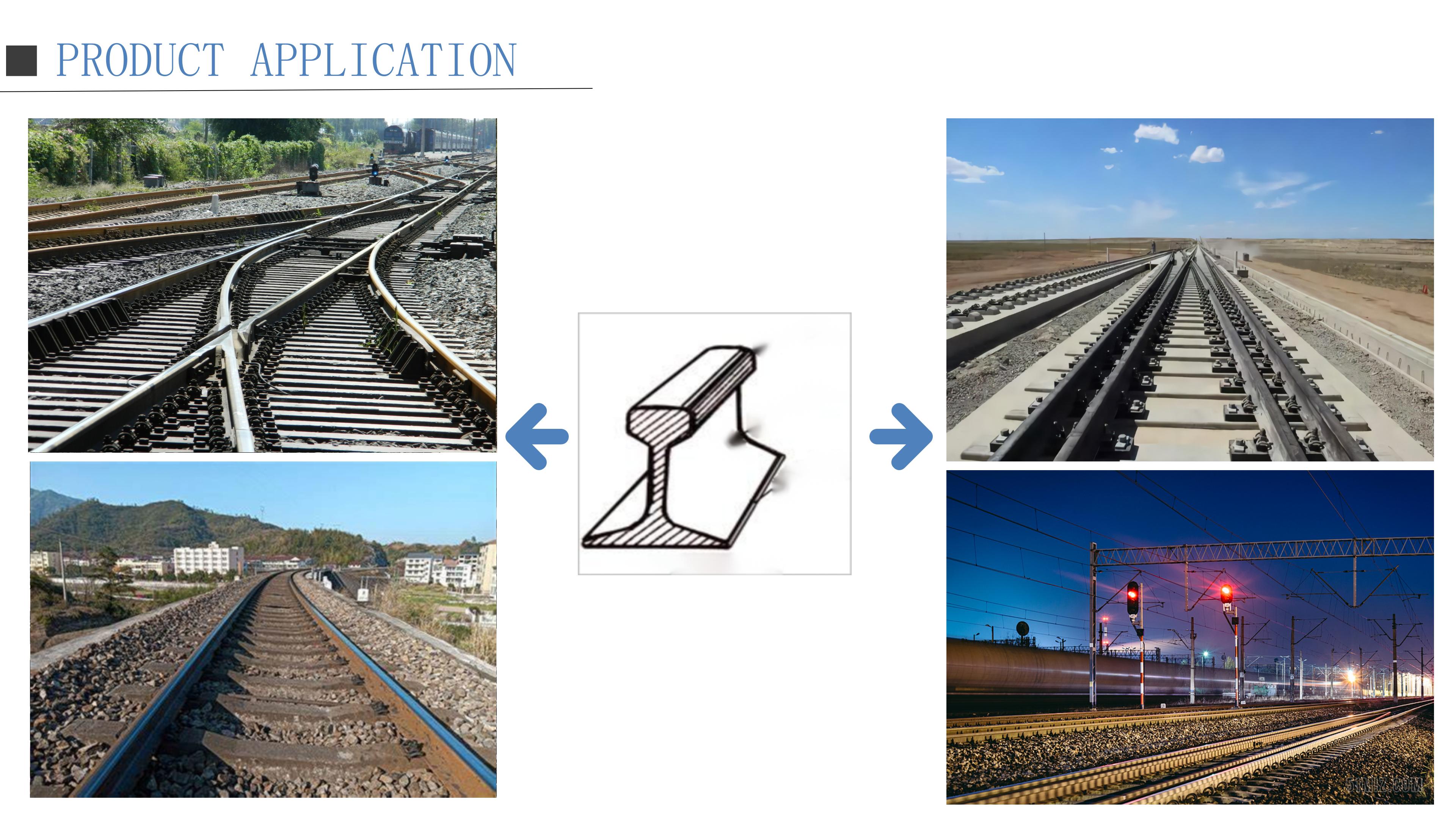

APPLICATION

Transportation field: Industrial rails are often used in industrial transportation systems, such as container trucks, cranes, airport luggage check-in equipment, etc.

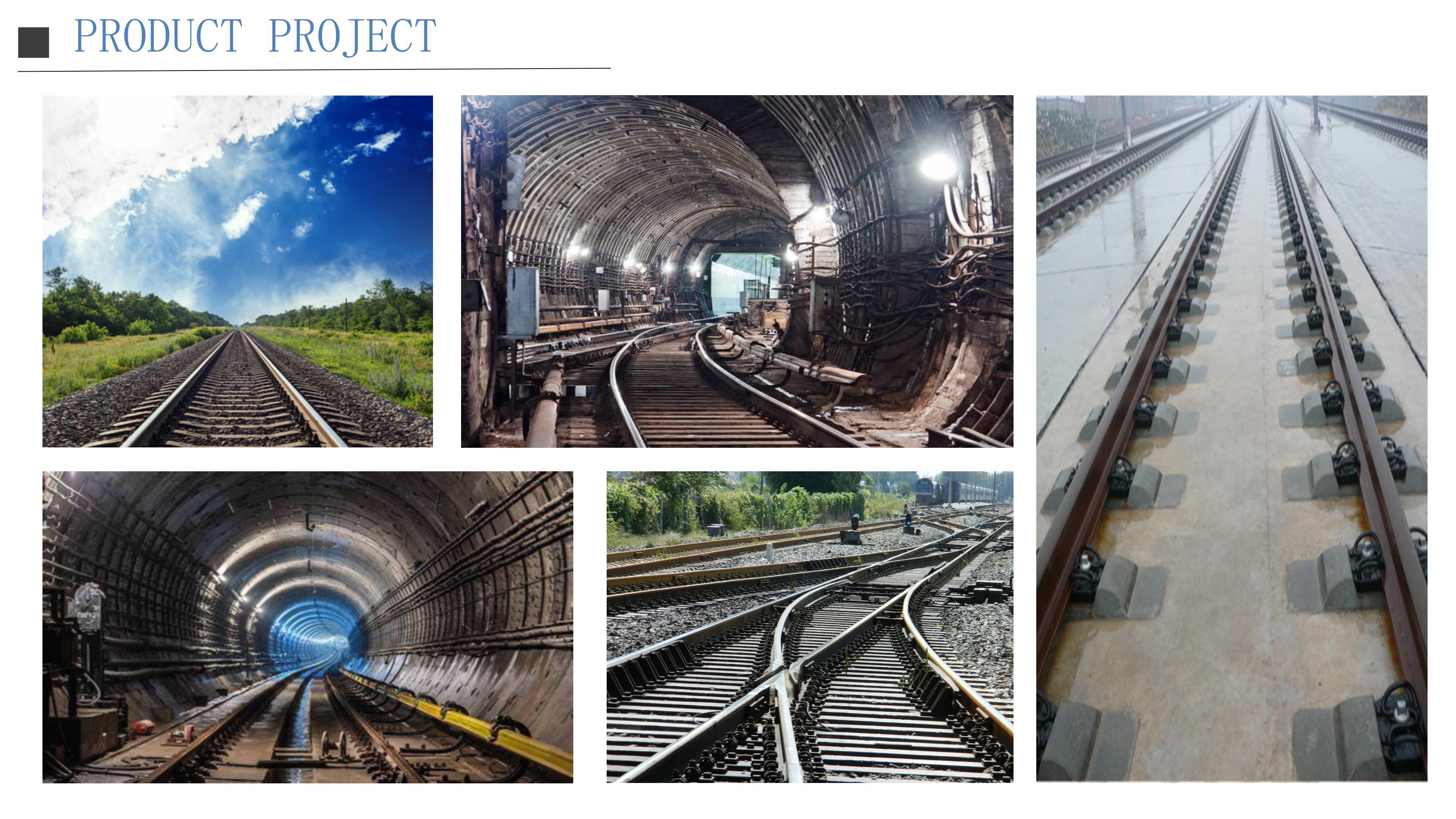

1. High-Speed Railways

Heavy-duty rails are one of the primary rail types used in high-speed railways. They are characterized by high strength and excellent stability, capable of meeting the high impact and crushing forces of high-speed trains. They also improve the rail's load-bearing capacity and service life.

2. Large Bridges

The construction of large bridges requires high-strength and stable rails to meet the demands of high-speed trains. Heavy-duty rails are also one of the preferred rail types in this area.

3. Tunnels

As important underground transportation channels, tunnel rails must possess sufficient stability and safety to ensure safe train operation. Heavy-duty rails are also a common rail type used in tunnels.

PACKAGING AND SHIPPING

1. Railway transportation

Steel railing are one of the commonly used goods in railway transportation. Railway transportation has the advantages of safety, speed and low cost. During transportation, attention should be paid to protecting the rails from damage, and special railway transportation vehicles are usually used for transportation. During the installation process, pay attention to the laying direction and connection methods to avoid errors caused by human factors.

2. Road Transport

Road transport is another common method for transporting long rails and is also a common method for railway construction or maintenance. During transportation, certain measures must be taken to prevent the cargo from sliding or swinging to avoid accidents. A detailed transportation plan should also be developed and implemented accordingly.

3. Water Transport

Long rails are typically transported over long distances by water. A variety of vessels are available for water transport, such as cargo ships and barges. Before loading, the length and weight of the rails, as well as the vessel's carrying capacity and safety features, must be considered to determine the appropriate loading method and quantity. Furthermore, protective measures must be taken to prevent accidental damage to the rails during transportation.

Transporting long rails is a critical undertaking, requiring careful attention to a series of operational specifications and safety precautions to avoid negligence that could lead to losses, casualties, and other adverse consequences.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.