Upn80/100 Steel Profile U-Shaped Channel Is Mostly Used In Construction

The UPE beam or U-section elements are parallel flange channels featuring a U-shaped cross-section, made of steel that provides strength and stability in construction and in industrial applications. Their design is intended to facilitate even weight distribution, making it possible for them to carry heavy weights without bending. Widely used in buildings, bridges and infrastructure, UPN beams are available in a variety of sizes and have good durability and high versatility.

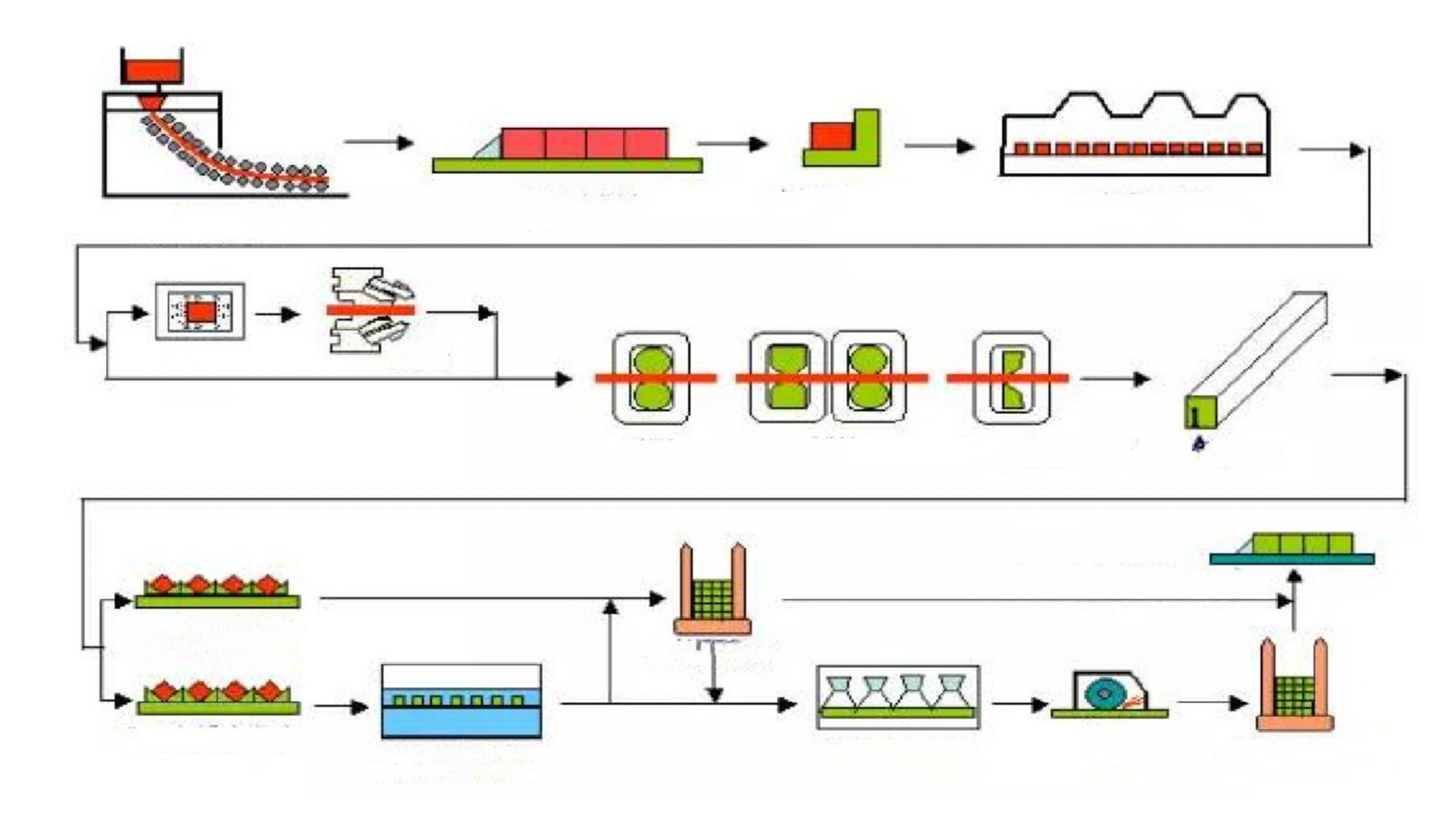

PRODUCT PRODUCTION PROCESS

Universal Beam production process

Production of channel steel goes through multiple closely monitored processes. First, the raw materials are prepared: the iron ore, limestone, coal and oxygen are processed to enable a steady flow. Then comes smelting, in which the substances are melted in a blast furnace and processed in a converter or an electric furnace. With the oxygen flow and pouring parameters we adapt the composition of the liquid molten steel for rolling.

The bright molten steel is then cast into billets, which go to the rolling mill. The billets are rolled over a sequence of hot working processes to channel steel in different sizes. Continuous water cooling maintains temperature and results in quality of the final product.

After rolling, the steel is cut to length according to customer requirements, usually by means of flame cutting. Each piece is rechecked to be sure it is within tolerance. Lastly, full-scale testing is performed, with this including a dimensional check, weight, mechanical properties and chemical analysis. Qualified channel steel is the only one which can make money.

In sum, channel steel processing is a tightly integrated system, dependent on accurately controlled processes. Through continuous technological enhancements, producers are increasing efficiency and providing higher quality products.

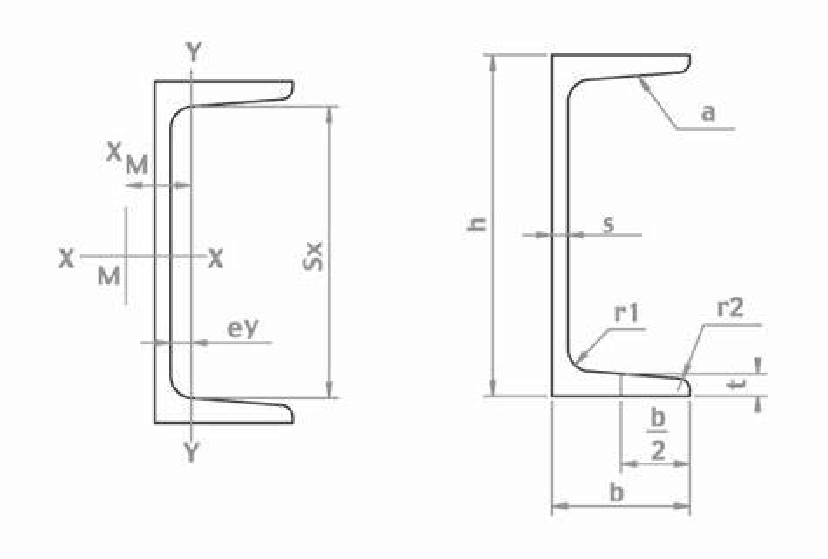

PRODUCT SIZE

| UPN EUROPEAN STANDARD CHANNEL BAR DIMENSION:DIN 1026-1:2000 STEEL GRADE:EN10025 S235JR |

|||||

| SIZE | H(mm) | B(mm) | T1(mm) | T2(mm) | KG/M |

| UPN 140 | 140 | 60 | 7.0 | 10.0 | 16.00 |

| UPD 160 | 160 | 65 | 7.5 | 10.5 | 18.80 |

| UPN 180 | 180 | 70 | 8.0 | 11.0 | 22.0 |

| UPN 200 | 200 | 75 | 8.5 | 11.5 | 25.3 |

Grade:

S235JR,S275JR,S355J2,etc.

Size:UPN 80,UPN 100,UPN 120,UPN 140.UPN160,

UPN 180,UPN 200,UPN 220,UPN240,UPN 260.

UPN 280.UPN 300.UPN320,

UPN 350.UPN 380.UPN 400

Standard:EN 10025-2/EN 10025-3

FEATURES

UPN H beam, also known as U-channels, are steel channels with the flanges parallel to each other and are available in various thicknesses and sizes. As such, they are applicable to a wide range of prestressed structural elements and are more aimed at standard-sized prestressing tendons. In addition to their strength and rigidity, U-shaped steel beams have great versatility and can be applied in numerous products and construction projects. Their consistent performance and customizable sizing make them a go-to for many building and infrastructure needs.

APPLICATION

UPN profile is widely used in construction and engineering due to its strength and flexibility. They’re a staple for building frames, bridge supports, industrial structures, and even machinery frames. Platforms, mezzanines, conveyor systems, equipment supports and even building façades and roofing structures. Because they are so versatile, I rely on them for many different kinds of projects.

PACKAGING AND SHIPPING

Packaging: Cover the ends and the center of the channel steel with fabric, plastic or the like and then tie up. It is the best way for single pieces or small quantity to avoid scratches or damages.

Pallet Packaging: Lay the channel steel on a pallet and strap it or wrap it in plastic. It can be used for transportation and handling if you have more.

Iron Case Packing: Packing the channel steel into an iron box, sealing it and reinforcing it with straps or plastic wrap. For long-term storage and ultimate protection.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

-

Scale Advantage: Large production and supply network ensures efficiency in procurement and transportation.

-

Diverse Products: Wide range of steel products including steel structures, rails, sheet piles, channel steel, silicon steel coils, and photovoltaic brackets to meet various needs.

-

Reliable Supply: Stable production lines and supply chain support large-volume orders.

-

Strong Brand: Well-known brand with significant market influence.

-

Integrated Service: One-stop solutions for production, customization, and logistics.

-

Competitive Pricing: High-quality steel at reasonable prices.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. How can I get a quotation?

Leave us a message, and we will respond promptly.

2. Will you deliver the goods on time?

Yes. We guarantee high-quality products and timely delivery. Honesty is our company’s core principle.

3. Can I get samples before placing an order?

Yes. Samples are usually free and can be made according to your sample or technical drawings.

4. What are your payment terms?

Our standard terms are 30% deposit, with the balance against B/L. We support EXW, FOB, CFR, and CIF.

5. Do you accept third-party inspection?

Yes, we do.

6. How can we trust your company?

We have years of experience in the steel industry as a verified gold supplier. Our headquarters is in Tianjin, China. You are welcome to verify us in any way.