Best Price Prime Quality 50*50 Q235 A36 5mm Thickness Hot-Dip Galvanized Carbon Steel Angles Equal ASTM Grade 50 Bending

Product Detail

Galvanized Angle Steel Bar is divided into hot-dip galvanized angle steel and cold-dip galvanized angle steel. Hot-dip galvanized angle steel is also called hot-dip galvanized angle steel or hot-dip galvanized angle steel. The cold-dip galvanized coating mainly ensures the full contact between the zinc powder and the steel through the electrochemical principle, and generates an electrode potential difference for anti-corrosion.

Hot-dip galvanized angle steel is also called hot-dip galvanized angle steel or hot-dip galvanized angle steel. It is to immerse the angle steel after derusting in the molten zinc at about 500 ℃, so that the surface of the angle steel is attached with a zinc layer, so as to achieve the purpose of anticorrosion, and it is suitable for various strong corrosive environments such as strong acid and alkali mist.

Process: hot-dip galvanized angle steel process: angle steel pickling → water washing → immersion in plating solvent → drying and preheating → rack plating → cooling → passivation → cleaning → grinding → hot-dip galvanizing completed.

The cold galvanizing process is used to protect metals from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the surface to be protected by any coating method. After drying, a zinc filler coating is formed. In the dry coating Has a high content of zinc (up to 95%). Suitable for repair work (i.e. during repair work, only where the protected steel surface has been damaged, it can be reapplied as soon as the surface has been repaired). The cold galvanizing process is used for the anticorrosion of various steel products and structures.

Main Application

Features

1. Low processing cost: the cost of hot-dip galvanizing and anti-rust is lower than that of other paint coatings;

2. Durable and durable: hot-dip carbon Steel Angle Bar has the characteristics of surface luster, uniform zinc layer, no missing plating, no dripping, strong adhesion and strong corrosion resistance. In the suburban environment, the standard hot-dip galvanized anti-rust thickness can be maintained More than 50 years without repair; in urban areas or offshore areas, the standard hot-dip galvanized anti-rust layer can be maintained for 20 years without repair;

3. High Reliability: The galvanized layer forms a metallurgical bond with the steel, becoming an integral part of the steel surface, ensuring a more durable coating.

4. Strong Coating Toughness: The galvanized layer forms a unique metallurgical structure that withstands mechanical damage during transportation and use.

5. Comprehensive Protection: Every part of the component is galvanized, ensuring comprehensive protection even for recessed areas, sharp corners, and hidden areas.

6. Time and Labor Savings: The galvanizing process is faster than other coating methods, eliminating the time required for on-site painting after installation.

Application

galvanized steel angle bar is widely used in power towers, communication towers, curtain wall materials, shelf construction, railways, road protection, street light poles, marine components, building steel structure components, substation ancillary facilities, light industry,etc.

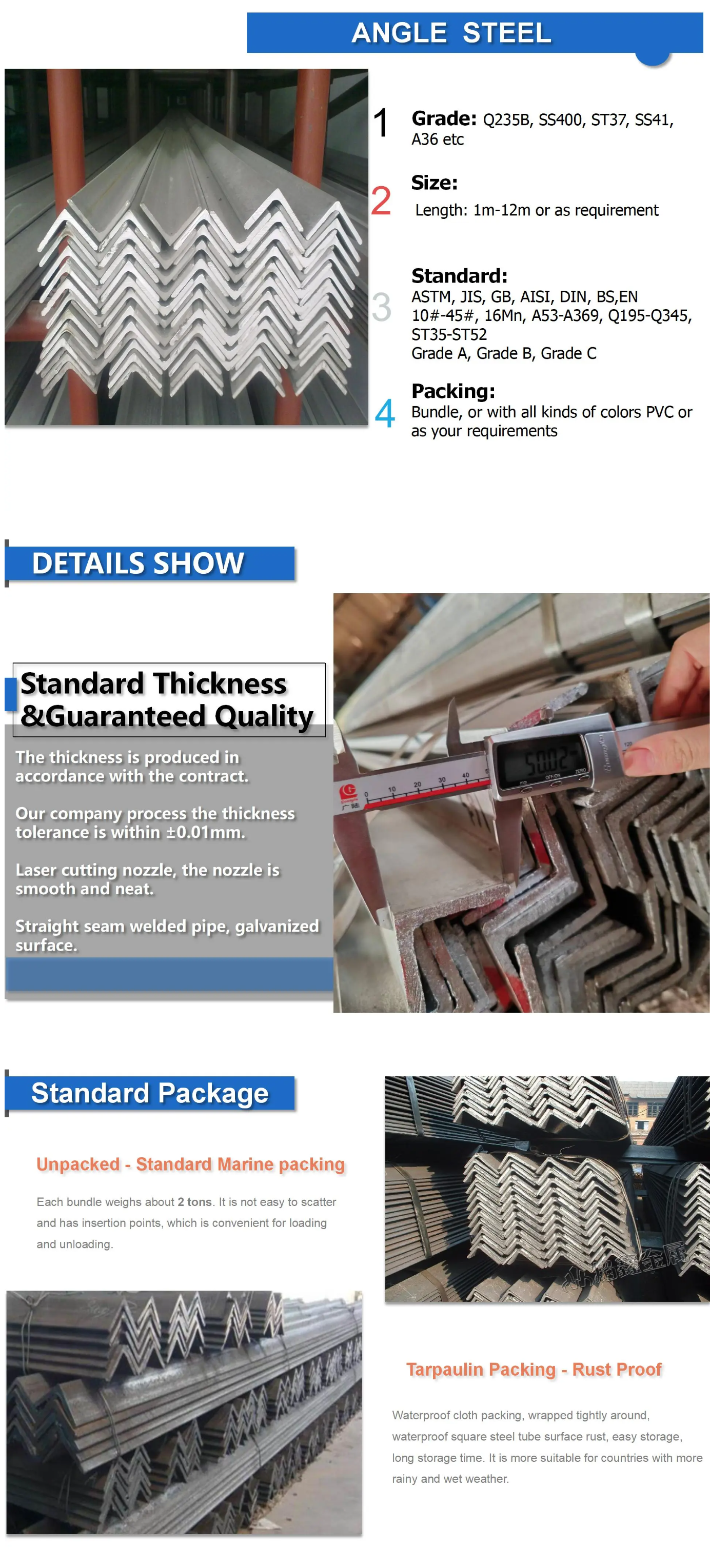

Parameters

| Product name | Angle Bar |

| Grade | Q235B, SS400, ST37, SS41, A36 etc |

| Type | GB Standard, European Standard |

| Length | Standard 6m and 12m or as customer requirement |

| Technique | Hot Rolled |

| Application | Wide used in curtain wall materials, shelf construction, railways etc. |

Details

Delivery

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.