Steel Profile

-

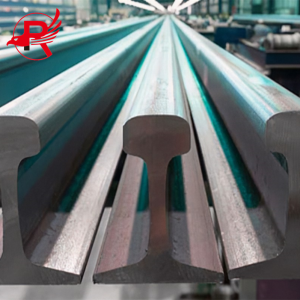

Wholesale Hot Rolled Grooved Heavy GB Standard Steel Rai lAnd Special Steel Crane Power Rail Sections

Steel rail is the main component of railway track. Its function is to guide the wheels of the rolling stock forward, withstand the huge pressure of the wheels, and transfer to the sleeper. The rail must provide a continuous, smooth, and least resistant rolling surface for the wheel. In electrified railway or automatic block section, the rail can also be used as a track circuit.

-

DIN 536 Crane Steel Rail A45 A55 A65 A75 A100 A120 A150 Standard Steel Rail Crane Rail

The material of the rail does not belong to ordinary steel, generally using high-quality carbon structural steel and low-alloy high-strength steel, with high strength, high wear resistance, high toughness and other characteristics, is an important support to ensure the safety and efficiency of railway transportation.

-

DIN Standard Steel Rail Standard Railway Carbon Steel Rail

Railway systems have been an integral part of human progress since the early 19th century, revolutionizing transportation and trade across vast distances. At the heart of these extensive networks lies the unsung hero: steel railroad tracks. Combining strength, durability, and precision engineering, these tracks have played a pivotal role in shaping our modern world.

-

Railroad DIN Standard Steel Rail Heavy Factory Price Best Quality Rails Track Metal Railway

DIN Standard Steel Rail is an important part of railway transport to carry the weight of the train, and it is also the infrastructure of the train. It is made of high-strength steel, has good strength and wear resistance, and can withstand great pressure and impact forces.

-

GB Standard Silicon Electrical Steel Coil ASTM Standard for Motor Use Cutting Bending Services Available

Silicon steel coils are widely used in various industries for their excellent magnetic properties. However, these coils come in various types, each suited for specific applications. By understanding the features and applications of each, you can make informed decisions when choosing the right silicon steel coil for your specific needs.

-

GB Standard Silicon Lamination Steel Coil/Strip/Sheet, Relay Steel and Transformer Steel

The silicon steel coils we are proud of have extremely high magnetic conductivity and low loss characteristics. Among them, the precise control of silicon content makes the silicon steel sheet have excellent magnetic induction intensity and low eddy current loss, thereby reducing the energy loss during the operation of the equipment, and the effect of energy saving and emission reduction is remarkable. In addition, the silicon steel coil also shows good punching shear performance and welding performance, making the processing more convenient and efficient, greatly meeting the needs of modern industry for high-performance, energy-saving and environmental protection materials.

-

50w600 50w800 50w1300 non oriented and grain oriented cold rolled magnetic induction GB Standard electrical silicon steel coil

Silicon steel core loss (referred to as iron loss) and magnetic induction strength (referred to as magnetic induction) as the product magnetic guarantee value. The low loss of silicon steel can save a lot of electricity, extend the operating time of motors and transformers and simplify the cooling system. The power loss caused by silicon steel damage accounts for 2.5% ~ 4.5% of the annual power generation, of which the transformer iron loss accounts for about 50%, 1 ~ 100kW small motor accounts for about 30%, and the fluorescent lamp ballast accounts for about 15%.

-

GB Standard Cold Rolled Grain Oriented Silicon Steel Crgo Electrical Steel Strips For Magnetic Transformer Ei Iron Core

Silicon steel coil is a light, low noise, high efficiency magnetic material made of electrical silicon steel plate. Due to the special composition and processing technology of silicon steel coil, it has high permeability, low iron loss and low saturation magnetic induction intensity, which makes it widely used in the power industry.

-

GB Standard Cold Rolled Grain Oriented Crgo Electrical Silicon Steel Sheet Coil Prices

Silicon steel refers to Fe-Si soft magnetic alloy, also known as electrical steel. The mass percentage of silicon steel Si is 0.4%~6.5%. It has high magnetic permeability, low iron loss value, excellent magnetic properties, low core loss, high magnetic induction intensity, good punching performance, good surface quality of steel plate, and good insulation film performance. Etc.

-

DIN Standard Steel Rail Quality Railway HMS /HMS 1 and 2, Railway Tracks in Bulk Railway

As the main supporting structure in railway transportation, the bearing capacity of rail is very important. On the one hand, DIN Standard Steel Rail needs to withstand the weight and impact of the train, and is not easy to deformation and fracture; On the other hand, under the continuous high-speed train, it is necessary to ensure the stability and reliability of the rail. Therefore, the primary feature of the rail is high strength to ensure the safety of the rail.

-

DIN Standard Steel Rail For Railway Is Cheap And High Quality

DIN Standard Steel Rail transportation, the strength of rail is very important. Steel rails need to bear train loads, transmit traction and limit the direction of vehicle movement, so their strength requirements are high.

-

DIN Standard Steel Rail Dedicated To The Construction Of Rail Rail For National Railways

During the use of the DIN Standard Steel Rail, it will be subjected to corrosion and hardening from air, water vapor, rain, train emissions and other factors. Therefore, it is necessary to have a certain corrosion resistance. It is recommended to protect the rail surface to improve its corrosion resistance and prolong its service life.