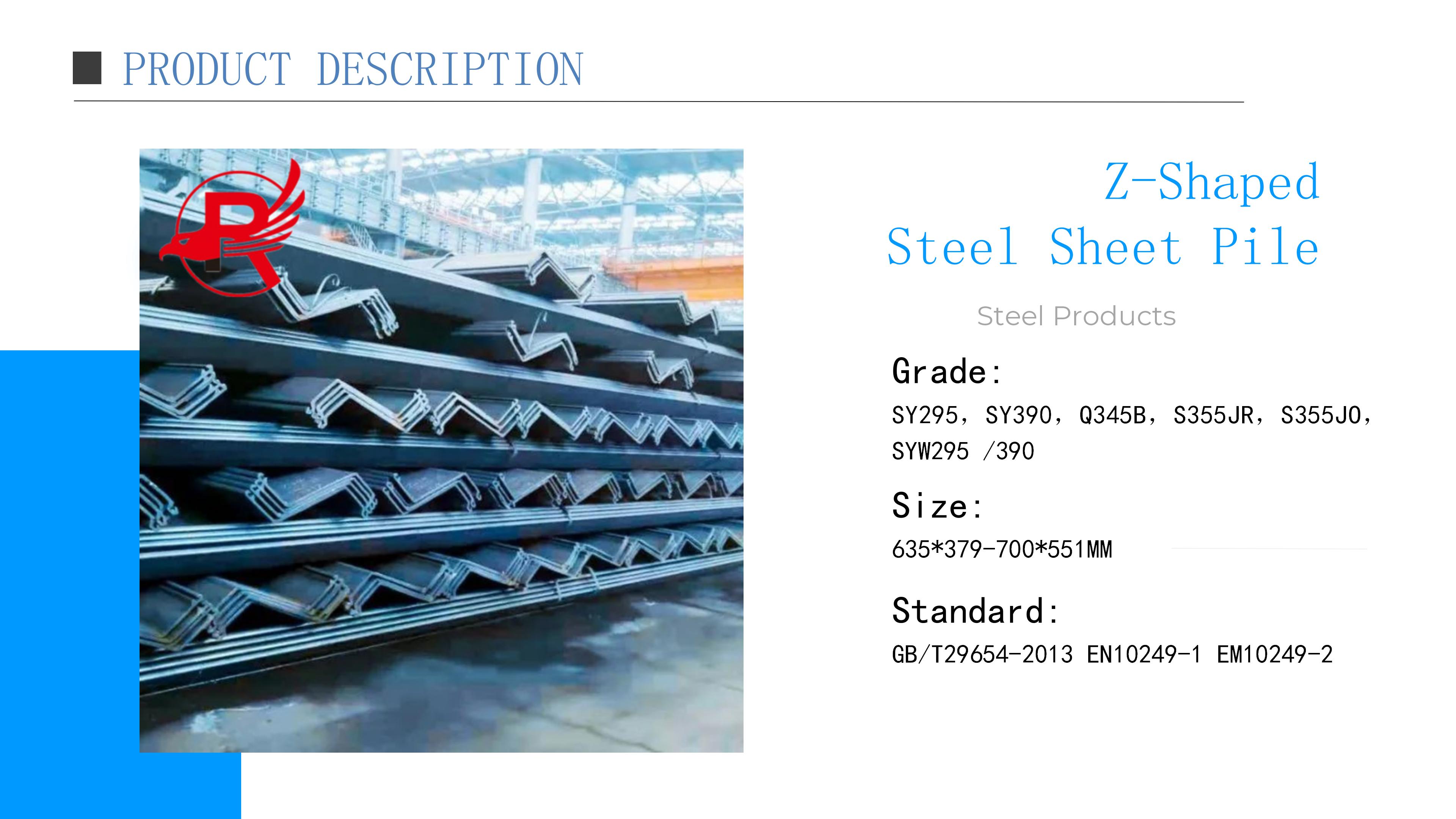

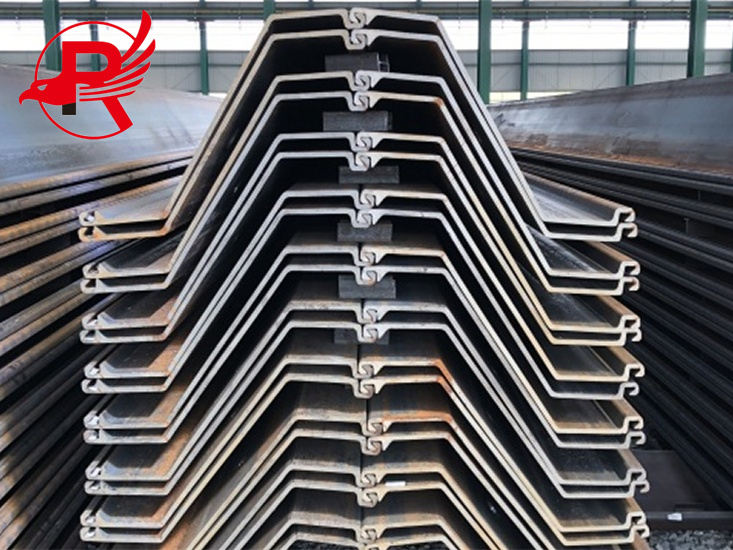

Steel Sheet Pile Factory Az12/Au20/Au750/Az580/Za680 Hot Rolled Sale Types of Steel Sheet Pile

PRODUCT PRODUCTION PROCESS

The production process of hot-rolled Z-shaped steel sheet piles usually includes the following steps:

Raw material preparation: First, raw materials need to be prepared, usually using high-quality steel as raw materials. These steels need to be inspected and classified to ensure they meet production requirements.

Heating and rolling: The raw materials are heated to bring them to the appropriate temperature and then rolled through the rolling mill. In this process, the steel is processed into a Z-shaped shape and rolled through multiple passes through different rollers to ensure that the shape and size of the final product meet standard requirements.

Cooling and shaping: After rolling, the steel needs to be cooled to stabilize its structure and properties. At the same time, shaping and trimming are also required to ensure that the product has a smooth surface and accurate dimensions.

Inspection and packaging: The completed steel sheet piles need to undergo strict quality inspection, including inspection of appearance quality, dimensional deviation, chemical composition, etc. Qualified products will be packed and ready to be shipped.

Factory and transportation: The final product will be loaded onto the truck and shipped out of the factory, ready to be shipped to the customer site for use. Care must be taken to protect the product during transportation to avoid damage.

The above is the general production process of Z-shaped steel sheet piles. The specific production process may vary depending on the manufacturer and equipment.

*Send the email to [email protected] to get a quotation for your projects

|

SPECIFICATIONS FOR Z SHEET PILE |

|

| 1. Size | 1) 635*379—700*551mm |

| 2)Wall Thickness:4—16MM | |

| 3)Z type sheet pile | |

| 2. Standard: | GB/T29654-2013 EN10249-1 |

| 3.Material | Q235B Q345B S235 S240 SY295 S355 S340 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)rolling stock |

| 2)Building steel structure | |

| 3Cable tray | |

| 6. Coating: | 1) Bared2) Black Painted (varnish coating)3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | Z type sheet pile |

| 9. Section Shape: | Z |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Free for oiled&marking3) All goods can be checked by third party inspection before shipment |

*Send the email to [email protected] to get a quotation for your projects

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Others available on request

Length

35.0m maximum but any project specific length can be produced

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

Grip Plate

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

Steel sheet piles have good performance in all kinds of complex soil condition, such as soft soil, silt, rock and so on. This gives them great potential for application in infrastructure works.

APPLICATION

High strength: The cross-sectional shape of steel sheet piles can be adjusted according to different construction needs, and it has high strength characteristics such as torsion resistance and bending resistance.

PACKAGING AND SHIPPING

Steel Sheet Pile Transportation Methods

1. Container Transportation

Ideal for small to medium steel sheet piles. This method is economical, efficient, and widely used in international shipping. Oversized piles cannot be shipped this way due to container size limits.

2. Bulk Transportation

Steel sheet piles are loaded directly onto vehicles without packaging, minimizing costs. Reinforcement such as tie-down straps and proper load-bearing vehicles is required to prevent damage.

3. Flatbed Truck Transportation

Suitable for larger or longer steel sheet piles. Safer than bulk transport, with different flatbed types (extendable or low-bed trailers) chosen based on pile length and weight.

4. Railway Transportation

Steel sheet piles are transported on specialized rail cars. Fast, safe, and cost-effective, but piles must be securely fastened and transport speed controlled to prevent damage.

COMPANY STRENGTH

Made in China · Premium Service · Leading Quality · Global Trust ·· Products are 100% made in China with competitive price, excellent service and high quality.

Scale Advantage With the wide range of supply chain, big steel processing base, we enjoy the procure and dispatch efficiency, the products from our company manufacture and service provided are under same roof.

Wide Product Range We do provide a diverse range of high quality and durable steel products including hot rolled bars, wires rods, cold rolled steel products, galvanized steel products, steel pipes, plates, structural steel products and many more to meet different requirements of the customers.

We provide a complete line of steel products — steel structure, steel rails, sheet pile, solar mounting system, channel steel, silicon steel coil, and so on making it easy and flexible to source everything you need for your project.

Reliable Supply Strong Production Line and Supply Chain is good to keep quality stable and delivery timely, especially in big quantity.

Strong Brand Influence As our influence and global market recognition continues to grow, so do the assurance and commitment for your business and the long term success.

Comprehensive Services We offer one stop steel services from customization, manufacturing, packaging to logistics transportation.

Competitive Pricing High-quality steel products at reasonable and affordable prices, to bring the maximum value for our clients.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

Q1: What is your company’s main business?

A1: We are the producers of steel sheet piles, steel rails, silicon steel, special steel and many more steel products.

Q2: When can I get my order?

A2: Normally the items in stock will be sent out within 5 to 10 days. Shipping & PaymentFor the out of stock or customized products, delivery time is 15 to 25 days on the respct of order quantity.

Q3: What advantages do your company have?

A3: We have professional production line, technical team to guarantee the quality products and stable supply .

Q4: Are you trading company or manufacturer?

A4: We are a factory, which has the independent production and export rights.

Q5: How to pay?

A5:Orders ≤ USD 1,000 (or equivalent): 100% payment in advance. ”

Orders ≥ USD 1,000: 30% T/T in advance and 70% T/T against the copy of shipping documents.