Steel Structure Building Warehouse/Workshop for Industrial Construction

Although steel has a larger bulk density, its strength is much higher. Compared with other building materials, the ratio of steel's bulk density to yield point is smaller. Under the same load conditions, when a steel structure is used, the self-weight of the structure is usually smaller.

Steel structures are designed individually according to the client's architectural and structural requirements, then assembled in a rational sequence. Due to the material's advantages and flexibility, steel structures are widely used in medium-sized and large-scale projects (e.g., prefabricated steel structures).

Steel structures also include secondary structures and other steel components of buildings. Each steel structure has a characteristic shape and chemical composition to meet the requirements of the project.

Steel is primarily composed of iron and carbon. Manganese, alloys, and other chemical components are also added to enhance strength and durability.

Depending on the specific requirements of each project, steel components can be formed by hot or cold rolling or welded from thin or bent plates.

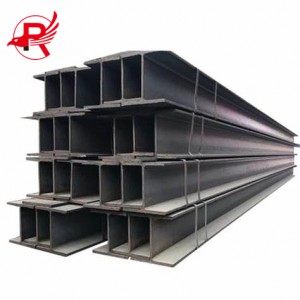

Steel structures come in a variety of shapes, sizes, and specifications. Common shapes include beams, channels, and angles.

When the span and load are the same, the weight of the steel roof truss is only 1/4-1/2 of the weight of the reinforced concrete roof truss, and it is even lighter if a thin-walled steel roof truss is used.

*Send the email to [email protected] to get a quotation for your projects

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | I-beam,H-beam,Z-beam,C-beam,Tube,Angle,Channel,T-beam,Track section,Bar,Rod,Plate,Hollow beam |

| Structural types: | Truss structure,Frame structure,Grid structure,Arch structure,Prestressed structure,Girder bridge,Truss bridge,Arch bridge,Cable bridge,Suspension bridge |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | Application : All kinds of industrial workshop ,warehouse ,high-rise building,Light Steel Structure House,Steel Structure School Building,Steel Structure Warehouse,Prefab Steel Structure House,Steel Structure Shed,Steel Structure Car Garage,Steel Structure For Workshop |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

Steel beams is an engineering structure made of steel and steel plates through welding, bolting or riveting. Compared with other constructions, it has advantages in use, design, construction and comprehensive economics. It has low cost and can be moved at any time. Features.

They offer excellent energy-saving benefits. Walls utilize lightweight, energy-saving, standardized C-shaped steel, square steel, and sandwich panels, providing excellent thermal insulation and seismic performance.

The use of steel structural systems in residential buildings fully utilizes the excellent ductility and strong plastic deformation capacity of steel structures, offering excellent earthquake and wind resistance, significantly improving residential safety and reliability. Steel structures can prevent building collapse and damage during disasters such as earthquakes and typhoons.

The total weight of steel-framed residential buildings is low, and the deadweight of steel-framed residential buildings is approximately half that of concrete structures, significantly reducing foundation costs.

Steel structures are constructed of steel and are one of the main types of building structures. They primarily consist of beams, columns, and trusses made from sections and steel plates. Rust-removing and anti-rust treatments such as silanization, pure manganese phosphating, water washing and drying, and galvanizing are used.

DEPOSIT

Because of its steel and structure, it is easy to transport and install. Therefore, it is especially suitable for structures with large spans, high heights, and large load-bearing loads. It is also suitable for structures that are movable and easy to assemble and disassemble.

PROJECT

Our company often exports steel structure products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

Whether you are looking for a contractor, a partner, or want to learn more about steel structures, please feel free to contact us to discuss further. We undertake a variety of light and heavy steel structure buildings, and we accept customized steel building designs.We can also provide the steel structure materials you need.We will help you quickly resolve your project issues.

*Send the email to [email protected] to get a quotation for your projects

PRODUCT INSPECTION

Steel structure manufacturing inspections are conducted after the steel structure is installed, primarily involving load and vibration testing. By testing the structural performance, we can determine the strength, stiffness, and stability of the steel structure under load, thereby ensuring its safety and reliability during use. In summary, steel structure inspections include material testing, component testing, connection testing, coating testing, nondestructive testing, and structural performance testing. These inspections effectively ensure the quality and safety of steel structure projects, thereby providing strong guarantees for the safety and service life of the building.

APPLICATION

Steel Structure Building is uniform in texture, isotropic, has a large elastic modulus, and has good plasticity and toughness. It is an ideal elastic-plastic body and is more in line with the concept of an isotropic body as the basis for calculations.

PACKAGING AND SHIPPING

Steel framework are easily affected by the external environment during transportation and installation, so they must be packaged. The following are several commonly used packaging methods:

1. Plastic film packaging: Wrap a layer of plastic film with a thickness of not less than 0.05mm on the surface of the steel structure to ensure that the goods are protected from moisture, dust and pollution, and to avoid scratching the surface during loading and unloading.

2. Cardboard packaging: Use three-layer or five-layer cardboard to make a box or box, and place it on the surface of the steel structure to ensure that there is no friction and wear between the panels.

3. Wooden packaging: Cover the baffle on the surface of the steel structure and fix it on the steel structure. Simple steel structures can be wrapped with wooden frames.

4. Metal coil packaging: Pack the steel structure in steel coils to fully protect it during transportation and installation.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT