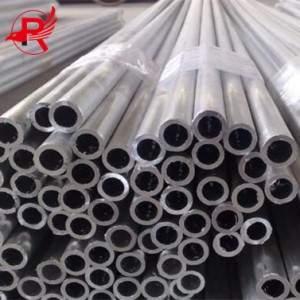

Aluminum Tube Supplier 6061 5083 3003 Anodized Round Pipe

Product Detail

Essential Information About Aluminum TUBE Pipes

Aluminum pipes are made with an aluminum alloy (most often 6063) that is very durable and suitable for numerous applications.

Size and Tolerance: Differing OD, ID and wall thickness with tight tolerance for consistency.

Surface Finish: Smooth finish can be in raw, polished or anodize finish with good appearance and protected from corrosion.

Mechanical properties: Tensile strength, Yield strength, Elongation, Hardness These are depended on alloy and temper.

Chemical composition: Aluminum containing alloying elements such as magnesium, manganese, copper or zinc according firstly to the industry standards and in some cases to the customer specifications.

Corrosion Resistance: The natural oxide layer and the addition of the alloying elements in 1100 makes it generally resistant to corrosion in many environments.

Joining Techniques: Depending on the diameter, alloy and application, it may be welded, brazed, or joined by means of mechanical couplings.

Note: Always consult supplier information or industry standards to determine the right alloy, size and finish for your application.

SPECIFICATIONS FOR ALUMINUM PIPES

|

Aluminum Tube/Pipe

|

||

|

Standard

|

ASTM, ASME, EN, JIS, DIN, GB

|

|

|

Specifcation for round pipe |

OD

|

3-300 mm,or customized

|

|

WT

|

0.3-60 mm,or customized

|

|

|

Length

|

1-12m,or customized

|

|

|

Specification for square pipe

|

SIZE

|

7X7mm- 150X150 mm,or customized

|

|

WT

|

1-40mm,or customized

|

|

|

Length

|

1-12m,or customized

|

|

| Material Grade |

1000 series: 1050, 1060, 1070, 1080, 1100, 1435, etc

2000 series: 2011, 2014, 2017, 2024, etc 3000 series: 3002, 3003, 3104, 3204, 3030, etc 5000 series: 5005, 5025, 5040, 5056, 5083, etc 6000 series: 6101, 6003, 6061, 6063, 6020, 6201, 6262, 6082, etc 7000 series: 7003, 7005, 7050, 7075, etc |

|

|

Surface treatment

|

Mill finished, anodized, powder coating, Sand blast, etc

|

|

|

Surface colors

|

Nature, silver, bronze, champagne, black, gloden or as customized

|

|

|

Usage

|

Auto /doors/decoration/construction/curtain wall

|

|

|

Packing

|

Protective film+plastic film or EPE+kraft paper,or customized

|

|

SPECIFIC APPLICATION

Typical Uses for Aluminum Pipes

HVAC Systems: Excellent thermal conductivity makes it ideal for coolant and refrigerant flow.

Plumbing: Corrosion-resistant, lightweight pipe used in water, gas and sewage systems.

Auto: Radiators, air intake, turbocharger and exhaust systems for weight reduction and improved heat transfer.

Industrial applications: liquid or gas transportation in the chemical, oil & gas, pharmaceutical, food & beverage and waste water industries.

Solar: Promotes Heat Transfer for solar water heating and thermal applications.

Building & Architectural: Structural, handrail, curtainwall and cladding applications requiring high performance and design versatility.

Electrical: High-conductivity alloys used for wiring, power transmission, and busbars.

Furniture and Interiors: Chairs, tables, shelving and curtain rods made from lightweight, customizable pipes.

Packaging & Shipping

Related processing guidelines: Aluminum pipe packaging & shipping.

Protective Packaging: Use strong cardboard tubes or box which is tight enough against the tubes.

Cushioning: Wrap with bubble pack or foam or with other shock absorbing material while in transit.

Secure Ends: Bottom and top ends of pipe are capped or taped to keep pipe end from moving.

Labeling: Write "Fragile" or "Handle with Care" on the parcels to warn the handlers.

Sealing: Seal the packaging with a packing tape well.

Stacking: Stack pipes in such a way that prevents them from sliding or rolling and that the weight is evenly distributed.

Fast and Reliable Shipping:Select a carrier that is experienced with fragile or sensitive items.