Advantages:

-

High section modulus-to-weight ratio for efficiency

-

Increased stiffness minimizes deflection

-

Wide design allows easy installation

-

Superior corrosion resistance, with extra thickness at critical points

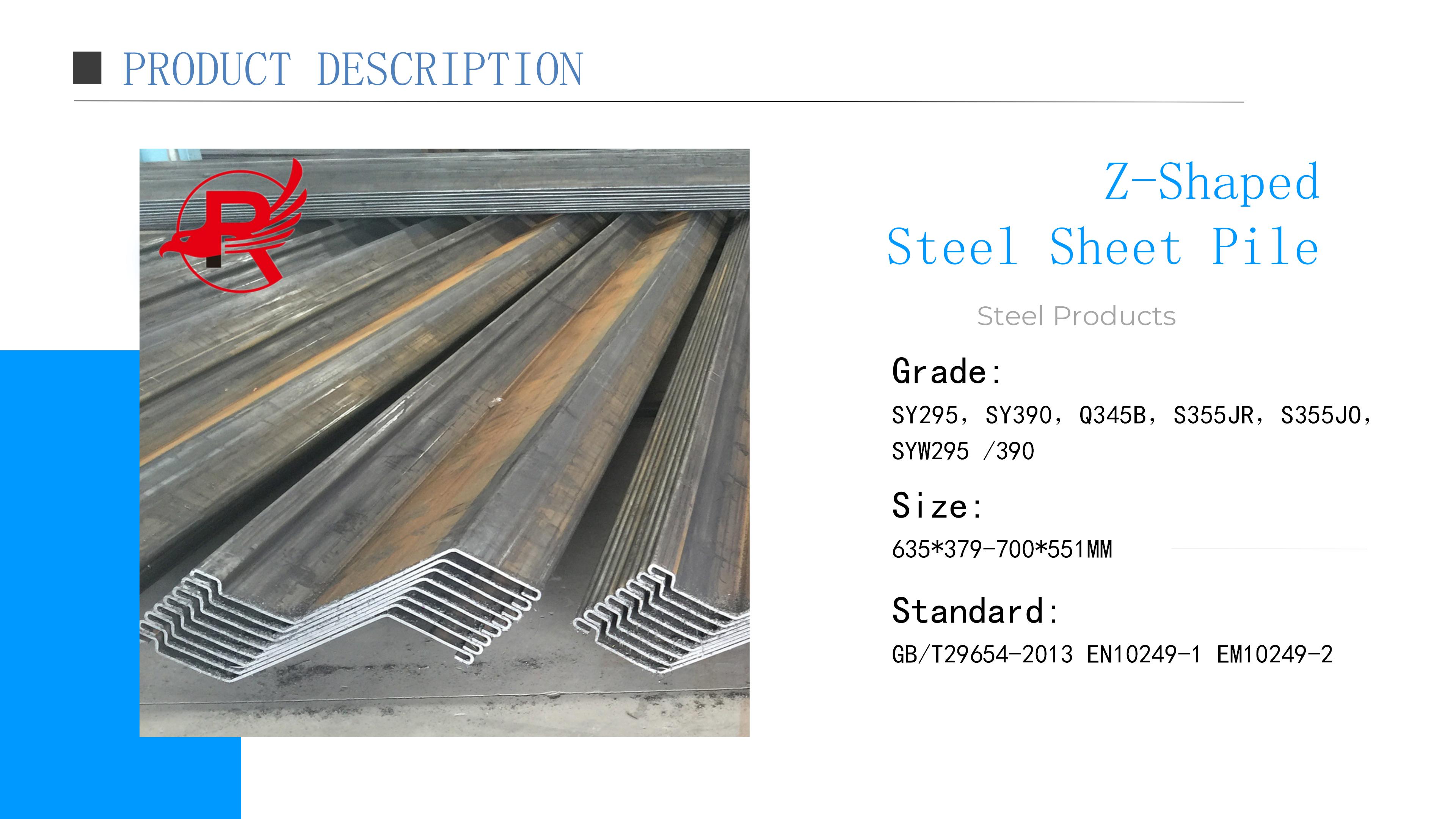

The height (H) of Z-shaped steel sheet pile usually ranges from 200mm to 600mm.

The width (B) of Q235b sheet pile usually ranges from 60mm to 210mm.

The thickness (t) of Z-shaped steel sheet piles usually ranges from 6mm to 20mm.

*Send the email to [email protected] to get a quotation for your projects

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Others available on request

Length

35.0m maximum but any project specific length can be produced

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

Grip Plate

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

|

Product Name

|

|||

|

MOQ

|

25 Ton

|

||

|

Standard

|

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc.

|

||

|

Length

|

1-12m or as Your Requirement

|

||

|

Width

|

20-2500 mm or as Your Requirement

|

||

|

Thickness

|

0.5 - 30 mm or as Your Requirement

|

||

|

Technique

|

Hot rolled or cold rolled

|

||

|

Surface Treatment

|

Clean, blasting and painting according to customer requirement

|

||

|

Thickness tolerance

|

±0.1mm

|

||

|

Material

|

Q195; Q235(A,B,C,D R); Q345(B,C,D R); Q345QC Q345QD SPCC SPCD SPCD SPCE ST37 ST12 ST15 DC01 DC02 DC03 DC04 DC05 DC06 20#- 35# 45#

50#, 16Mn-50Mn 30Mn2-50Mn2 20Cr, 20Cr, 40Cr 20CrMnTi 20CrMo;15CrMo;30CrMo 35CrMo 42CrMo; 42CrMo4 60Si2mn 65mn 27SiMn ;20Mn; 40Mn2; 50Mn; 1cr13 2cr13 3cr13 -4Cr13; |

||

|

Application

|

It is widely used in small tools, small components, iron wire, siderosphere, pull rod, ferrule, weld assembly, structural metal,

connecting rod, lifting hook, bolt, nut, spindle, mandrel, axle, chain wheel, gear, car coupler. |

||

|

Export packing

|

Waterproof paper, and steel strip packed.Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

|

||

|

Application

|

Shipbuilding,marine steel plate

|

||

|

Certificates

|

ISO,CE

|

||

|

Delivery Time

|

Usually within 10-15 days after receipt of advance payment

|

||

The interlocking structure of the outer fibers optimizes the cross-sectional profile, achieving high strength and low material weight.

High inertia reduces deflection and improves performance.

High steel grade provides an efficient cross-section with high bending moment resistance.

Uniform cross-sectional thickness ensures good driving stiffness.

The system is wider than standard sheet piles. This greater width reduces handling and installation time using conventional driving equipment.

The greater width reduces the number of interlocks per meter of wall length, directly improving the wall's waterproofing.

Z steel sheet piles have a wide range of applications in civil engineering and construction. Some common applications include:

The width of steel sheet pile is that it has a very wide profile, in building permanent structures can be applied for wharf, unloading yard, embankment lining, wall, retaining wall, breakwater, diversion embankment, dock, gate, etc.; in temporary structures, is can be used to seal mountain, shore expansion, cut-off, bridge cofferdam, pipeline laying large temporary ditch excavation, holding water, sand, etc.; Fighting floods, can be applied to prevent floods, collapsing, sand and other applications.

![0$NU_O5TD8Y4}`E3UXEVP]2](http://www.chinaroyalsteel.com/uploads/0NU_O5TD8Y4E3UXEVP2.jpg)

Packaging:

Stacked the sheet piles:Neatly and securely stack the Z sheet piles they should be aligned and should not slide in any direction. Apply a band/strap or two to the sheet piles for whatever distance you need to hold them together to keep them from moving while you transport them.

Use Protective Packaging: Cover the sheet piles with a moisture-resistant packaging (eg plastic or waterproof paper) to shield it from water, moisture and other environmental conditions. This prevents rust and corrosion.

Transportation:

Select suitable Transport: According to the quantity and weight of the sheet piles, decide a suitable mode of transport, such as flatbed truck, container, ship. Take into account transportation distance, time, cost, and possible related regulations.

Use suitable lifting equipment: Load and unload U-shaped sheet piles with suitable lifting equipment, such as a crane, forklift, or loader. Make sure it's adequately rated to safely carry the load of the sheet piles.

Secure the load: Strap, brace or otherwise secure the baled sheet pile stack to the transport vehicle to prevent shifting, sliding or falling while in transport.

The production process of cold-formed steel sheet pile usually includes the following steps:

1.Material Preparation: Select hot-rolled or cold-rolled steel plates that meet design requirements and relevant standards.

2.Cutting: Cut the steel plates to required lengths to form blanks.

3.Cold Bending: Form the blanks into Z-shaped cross-sections using rolling and bending machines.

4.Welding: Weld the Z-shaped piles to ensure strong, defect-free connections.

5.Surface Treatment: Apply rust removal, painting, or other treatments to enhance corrosion resistance.

6.Inspection: Check appearance, dimensions, and weld quality to ensure compliance with standards.

7.Packaging & Dispatch: Package and label qualified piles before shipping from the factory.

*Send the email to [email protected] to get a quotation for your projects

When a customer wants to look at a product, these options are usually available:

Schedule a visit to see the product: Buyers can also reach out to the manufacturer or sales rep directly to arrange a time and place to take a closer look at the product.

Book a guide tour: Book an expert or a sales assistant as your guide to take you through the manufacturing process, technology and quality control system of the product.

Demonstrate products: Present products in different phases of production to your guests during tours so they may learn about how your products are produced and the quality of your products.

Satisfy inquiries: Of course, during the visit, customers may have some doubts, and the guide or sales should be patient to answer questions, and can provide some related technical and quality knowledge.

Offer samples: You may be able to deliver a few samples of the product to the customers so they can get a better feel of the quality and features of your product.

Take further action: Wait on the customer feedback, if any, and if new demand is expressed, try to fulfill it and provide further services to the customer.

Choosing our China-made steel sheet piling and shoring solutions guarantees quality and durability. We are China Az Sheet Pile Supplier.Our sheet piles are manufactured to the highest standards, ensuring they can withstand the rigors of any construction environment.

Quality and Durability

With our dedication for quality, our products are long-lasting sheet piles and shoring. They are resistant to corrosion, can be subjected to large bending moments and to heavy loads without losing their integrity. This makes a solid and reliable base for building your project.

Excellent Customer Service and Support

We understand the importance of support throughout the construction process. Therefore, we offer exceptional customer service and expert guidance during sheet pile and shoring design and installation. Our team, including our in-house engineering team, is dedicated to providing you with the best shoring solution to ensure your project's success.We can provide all the sizes you need, including Az Sheet Pile Dimensions, Pz Sheet Pile Dimensions, Nz Sheet Pile Dimensions.

Q: Are you trading company or manufacturer ?

A: We are manufacturer, with own warehouse and trading company.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or 15-20 days if the goods are not in stock, according to order quantity.

Q: Do you provide samples ? Is it free or extra cost?

A: Yes, we provide the sample for free, customer affords freight charge.

Q: What about your MOQ?

A: 1 Ton is acceptable, 3-5 Tons for customized product.