ASTM Standard A683 Cold Rolled Non-Oriented Electrical Silicon Steel(CRNGO) Coil

Product Detail

General Information

| Item | Description |

|---|---|

| Product Name | ASTM A683 Silicon Steel Coil |

| Steel Type | Non-Oriented Electrical Steel (CRNGO) |

| Manufacturing Process | Cold-Rolled Non-Oriented (CRNGO) |

| Standard | ASTM A683 / A683M |

| Application Frequency | 50 / 60 Hz |

Chemical Composition (Typical)

| Element | Content |

|---|---|

| Silicon (Si) | 2.5 – 3.2 % |

| Carbon (C) | ≤ 0.005 % |

| Sulfur (S) | Strictly controlled |

| Nitrogen (N) | Strictly controlled |

| Iron (Fe) | Balance |

Physical & Magnetic Properties

| Property | Description |

|---|---|

| Grain Orientation | Non-oriented for uniform magnetic properties |

| Core Loss | Low |

| Magnetic Permeability | Good |

| Magnetic Induction | High |

| Performance Stability | Stable under continuous operation |

Available Thickness

| Thickness (mm) | Typical Application |

|---|---|

| 0.35 | Small & medium motors, generators |

| 0.50 | Industrial motors, general-purpose transformers |

| 0.65 | Large motors, generators, industrial equipment |

| 0.80 | High-performance motors, automotive EV drive motors |

ASTM A683 Silicon Steel Coil Size

| Trademark (Reference) | Nominal Thickness (mm) | Density (kg/dm³) | Typical Core Loss W/kg (1.7T / 50Hz) | Minimum Magnetic Induction B50 (T) | Minimum Stacking Coefficient (%) |

|---|---|---|---|---|---|

| A683-350 | 0.35 | 7.65 | 1.10 | ≥ 1.65 | ≥ 95.0 |

| A683-500 | 0.50 | 7.65 | 1.25 | ≥ 1.66 | ≥ 95.0 |

| A683-650 | 0.65 | 7.65 | 1.40 | ≥ 1.67 | ≥ 94.5 |

| A683-800 | 0.80 | 7.65 | 1.55 | ≥ 1.68 | ≥ 94.0 |

ASTM A683 Silicon Steel Coil Customized Content

| Customization Category | Available Options | Description / Notes |

|---|---|---|

| Dimensions | Thickness, width, coil weight | Thickness: 0.35 / 0.50 / 0.65 / 0.80 mm; Width: 600–1,200 mm; Coil weight: 3–8 MT or as required |

| Magnetic Grade | Core loss levels (W/kg), isotropic properties | Magnetic loss grades customized for motors, generators, and industrial equipment |

| Processing | Slitting, cut-to-length, edge trimming, stress relief annealing | Coils can be slit into narrow strips or cut into sheets for motor and generator core manufacturing |

| Surface Insulation | C2, C5, C6 insulation coatings | Coatings improve interlaminar resistance and reduce eddy current loss |

| Grain Orientation | Non-oriented (uniform in all directions) | Ensures consistent magnetic performance for rotating machinery |

| Marking & Packing | Heat number, coil ID, magnetic grade labels, seaworthy packing | Each coil labeled with standard, grade, size, batch number; packed for long-distance export |

Application

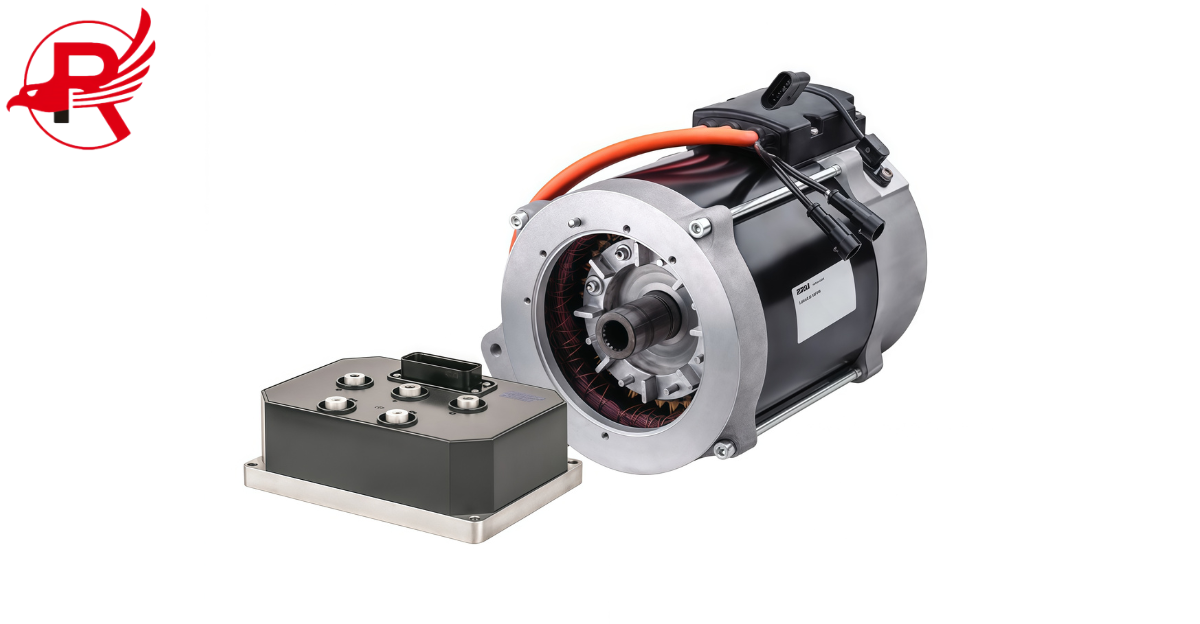

Electric Motors: Suitable for AC, DC, and servo motors; provides uniform magnetic properties, achieving smooth rotation and low energy loss.

Generators and AC Generators: Non-oriented silicon steel sheets ensure stable performance in rotating magnetic fields, suitable for power generation.

Industrial Transformers and Reactors: For small to medium-sized industrial transformers and reactors requiring isotropic magnetic properties.

Electric Vehicle Drive Motors: High-performance motors suitable for electric and hybrid vehicles, featuring low iron losses and uniform magnetic induction.

Renewable Energy Generators: Wind turbines, hydroelectric generators, and other renewable energy generators requiring high consistency in magnetic properties.

Why Choose Royal Steel Group

1. Reliable Supply of ASTM A683 Silicon Steel

2. Good Magnetic Properties

3.Wide Specification & Custom Processing

4.Stringent quality control & full traceability

5.Experience in exporting and global logistics support

6.Application-oriented Technical support

Packaging & Shipping

Packaging

Maintenance-Free Protection: Each Coil covers by High Intensity Plastic Film, prevent moisture and rust and surface damage while transportation.

Seaworthy Packing for Export:Coils are packed by wooden or steel pallet for the container shipment.

Identification & Traceability: Each coil is marked with grade, thickness, width, batch/heat number and any customer specific project code.

Optional Customized Packaging: The packaging may be customized according to the distance of transportation, weather conditions and any other special requirements from customers.

Shipping & Logistics

Transport Adapted: For the size of your project, choose between FCL (Full Container Load), LCL (Less than Container Load) or by truck.

Reliable Delivery: Royal Steel Group partners with seasoned shippers to keep customers’ projects on schedule, not delayed.

Extensive experience: We have been very successful in shipping to North America, Latin America, South East Asia, Europe and more.

Tailored Documentation: We can provide full export documentation including MTC (EN 10204 3.1), packing list, invoice and certificates.

FAQ

Q1: What is it used for?

A1: Electric motors, generators, industrial transformers, and other rotating electrical machines.

Q2: What thicknesses are available?

A2: 35mm, 0.50mm, 0.65mm, 0.80mm (custom sizes available).

Q3: Can it be slit or cut-to-length?

A3: Yes, slitting and cut-to-length services are available.

Q4: What surface coatings are available?

A4: C2, C5, or C6 insulation coatings.

Q5: How is it packed?

A5: Moisture-proof wrapped, labeled, and shipped on wooden or steel pallets.