Carbon Steel Rolled Forged Rolled Bars China Alloy Steel Round Bars

Product Detail

| Item | Details |

|---|---|

| Product Name | AISI 4140 / 4340 / 1045 Hot Forged Steel Round Bar |

| Material Standard | AISI / SAE Alloy & Carbon Steel |

| Product Type | Hot Forged Round Bar (Square / Flat on request) |

| Chemical Composition | 1045: C 0.43–0.50%; Mn 0.60–0.90% 4140: C 0.38–0.43%; Cr 0.80–1.10%; Mo 0.15–0.25% 4340: C 0.38–0.43%; Ni 1.65–2.00%; Cr 0.70–0.90%; Mo 0.20–0.30% |

| Mechanical Properties | Yield Strength: 310–470 MPa (by grade) Tensile Strength: 585–930 MPa (by grade) Elongation: ≥ 16–20% |

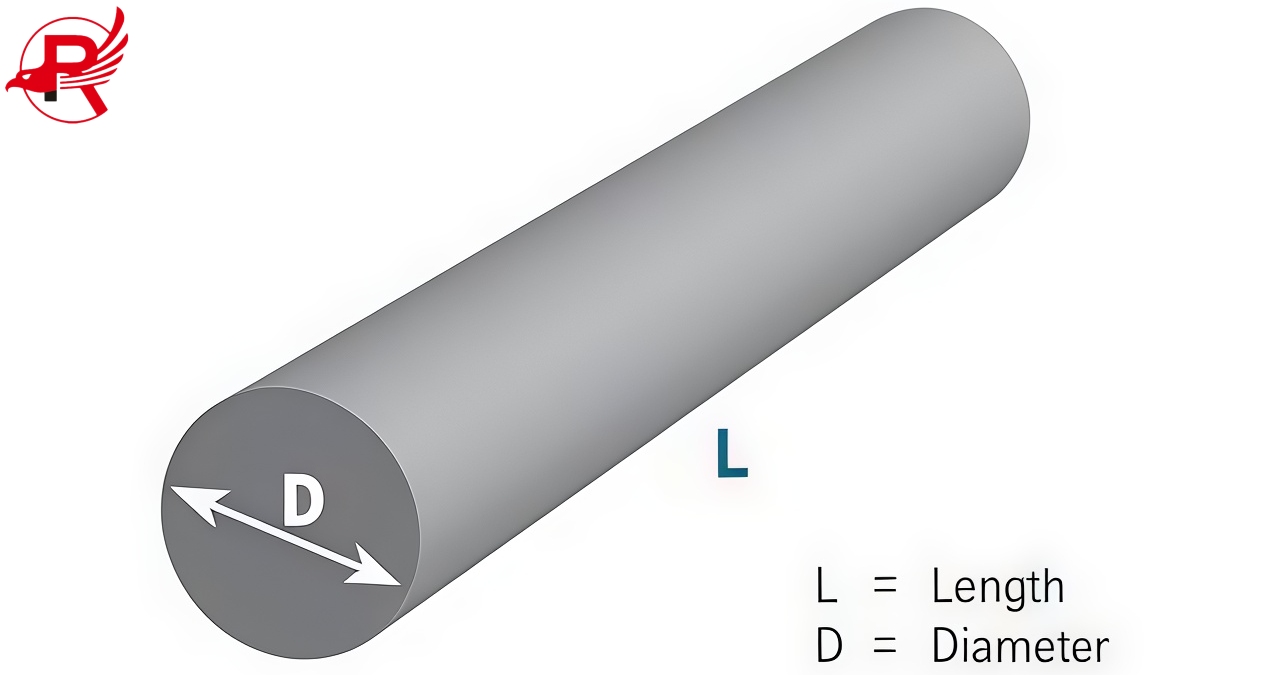

| Available Sizes | Diameter: 20–600 mm; Length: 6 m / 12 m / Cut-to-length |

| Surface Condition | Black / Machined / Peeled / Polished |

| Heat Treatment | Annealed, Normalized, Quenched & Tempered |

| Applications | Shafts, gears, axles, hydraulic parts, oil & gas tools, heavy machinery |

| Advantages | High strength, dense structure, excellent toughness, good fatigue resistance |

| Quality Control | Mill Test Certificate (EN 10204 3.1); ISO 9001 |

| Packing | Steel-strapped bundles or wooden cases, seaworthy export packing |

AISI 4140 4340 1045 Round Steel Bar Size

| Diameter (mm / in) | Length (m / ft) | Weight per Meter (kg/m) | Approx. Load Capacity (kg) | Notes |

|---|---|---|---|---|

| 20 mm / 0.79 in | 6 m / 20 ft | 2.47 kg/m | 1,200–1,500 | AISI 1045 / 4140, light-duty shafts |

| 25 mm / 0.98 in | 6 m / 20 ft | 3.85 kg/m | 1,800–2,200 | Good machinability, general mechanical parts |

| 30 mm / 1.18 in | 6 m / 20 ft | 5.55 kg/m | 2,500–3,000 | AISI 4140 forged, transmission components |

| 32 mm / 1.26 in | 6–12 m / 20–40 ft | 6.31 kg/m | 3,000–3,600 | Medium-load structural & machinery use |

| 40 mm / 1.57 in | 6 m / 20 ft | 9.87 kg/m | 4,500–5,500 | AISI 4140 Q&T, axles & hydraulic rods |

| 50 mm / 1.97 in | 6–12 m / 20–40 ft | 15.42 kg/m | 6,500–8,000 | AISI 4340 forged, high-stress components |

| 60 mm / 2.36 in | 6–12 m / 20–40 ft | 22.20 kg/m | 9,000–11,000 | Heavy-duty shafts, oil & gas tools |

AISI 4140 4340 1045 Round Steel Bar Customized Content

| Category | Options | Notes |

|---|---|---|

| Dimensions | Diameter, Length | Ø20–Ø300 mm; 6 m / 12 m or cut-to-length |

| Processing | Cutting, Threading, Machining, Drilling | Customized processing per drawings or application |

| Heat Treatment | Annealed, Normalized, Q&T | Selected based on required strength and service conditions |

| Surface Finish | Black, Turned, Peeled, Polished | Chosen for accuracy and appearance needs |

| Tolerance | Standard / Precision | Straightness and tight tolerances available |

| Marking & Packing | Custom labels, Heat No., Export packing | AISI grade & heat number marked; steel-strapped bundles or wooden cases |

Surface Finish

Carbon Steel Surface

Galvanized Surfce

Painted Surface

Application

1.Civil & Residential Construction: Ensuring the vital structural stability of skyscrapers and apartment buildings.

2.Infrastructure & Public Works: Vital to the bridge piers, girders, and reinforced concrete pavements that must resist enormous traffic load.

3.Industrial Engineering: Heavy flooring and machinery bases for factories and storage houses.

4.Manufacturing & Hardware: Superior quality round bars for the manufacture of bolts, nuts, shafts, and gears.

Our Advantages

Superior Bonding: Our deformed bars are designed with optimized rib patterns to provide maximum bond with concrete.

Good Weldability: The chemical composition of the quality makes it easier to weld at site without loosing strength.

Custom Lengths: Standard 6m, 9m and 12m lengths are available or tailored to your specific blueprints to reduce waste on site.

*Send the email to [email protected] to get a quotation for your projects

Packaging & Shipping

Standard Packing:Steel bars are tightly banded to keep them from moving and rusting. Wooden blocks or other bracing are added to stabilize the load for long distance haul.

Bespoke Packaging:Labels may refer to the steel grade, diameter, length, batch number, or project information. For sensitive surfaces palletizing and protective wrapping are offered.

Shipping Options:Shipments are reserved by container and flat rack or via local trucking according to the quantity and location. Full truckload (FTL) and less-than-truckload (LTL) services are also available.

Handling & Safety:Packaging is intended to allow safe handling, loading and unloading, for domestic and international transport.

Lead Time:The standard lead time is 7–15 days per order, expedited services available for large or repeat order.

FAQ

Q1: What grades of steel do you offer?

A: We can provide AISI 1045, 4140, 4340 etc. other grades are available on request.

Q2: What dimensions can I get?

A: Diameter from Ø20 to Ø600 mm, length 6 m, 12 m or as cut-to-length.

Q3: What are the heat treatment possibilities?

A: There are three states available, annealed,normalised and quenched & tempered (Q&T).

Q4: Can you do the processing?

A: Yes to the processing services you can also enjoy cutting, machining, drilling and threading according to drawings.

Q5: Can we receive the certificates of quality?

A: Yes, all our products are accompanied with EN 10204 3.1 MTC.