Cheap Welding Pre Fabricated Steel Structure

The application of steel structures for buildings and engineering works is tremendously broad and the building types include (but are not limited to):

Commercial Buildings:

Steel structures used in shopping centres, hotels, offices offer large dimensions and flexible solutions, answering to the requirements of a wide range of architectonic layouts.

Industrial Facilities:

Great for factories, warehouses, and work shops, they’re built to hold heavy loads, and assembled quickly.

Bridge Engineering:

Hiway, Railway and Urban Transit bridges are erected with steel, they are light, offer long spans and are constructed quickly.

Sports Venues:

No wonder they’re ideal for stadiums, gymnasiums and swimming facilities, the fact that their column-free designs enables wide, uninterrupted views makes them a natural fit for buildings focused

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What should you pay attention to when making a steel structure house?

Guarantee the layout of the floor – Cut and position rafters spaced appropriately for the attic floor design and do not hit or dent the steel while working to avoid the creation of a safety hazard.

Select Right Steel – Use strong quality solid steel instead of hollow pipes and coat interiors to avoid rust.

Keep the Layout Simple – Conduct accurate stress analysis to reduce vibrations and make sure strength and beauty.

Put on Protective Layer – Paint welded steel frames with anti-rust agent to delay corrosion and maintain security.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

Embedded Components to Firm up the factory building.

Columns – Typically H-beams or two C-channels running parallel and joined by angle steel.

Beams – Generally H or C shaped steel, the height of the beam depends on the span.

Rods/Bracing – Primarily C-channel or standard channel steel.

Roof Panels – Color steel sheets single layer or insulated composite panels (EPS, rockwool, PU) to provide thermal and sound insulation.

PRODUCT INSPECTION

Steel structure precast engineering inspection mainly involves raw material inspection and main structure inspection. Among the steel structure raw materials that are often submitted for inspection are bolts, steel raw materials, coatings, etc. The main structure is subjected to weld flaw detection, load-bearing testing, etc.

Scope of Inspection:

For the steel and welding materials, fasteners, bolts, plates, polymer sleeves and coatings, welds, roof and general connections, torque of high strength bolts, processing of components and dimensions of assembly, single and multi story and tolerances for installation of grid structures and coating thickness.

Item Test:

Visual, non-destructive (UT, MT, etc.), mechanical (tensile, impact, bending), metallographic, chemical composition, weldment quality, dimensional precision, coating adhesion and thickness, corrosion and weather proof, fastener torque and strength, structural verticality, and determination of strength, stiffness and stability of.

PROJECT

Our enterprise is often required to the steel structure workshop products to the Americas and Southeast Asia. Among our biggest contracts in the the whole of the Americas involves a area of about 543,000 square meters and 20,000 tons of steel. When the work is completed, it will provide a full range of production living, office work, education and tourism functions in a steel structure complex.

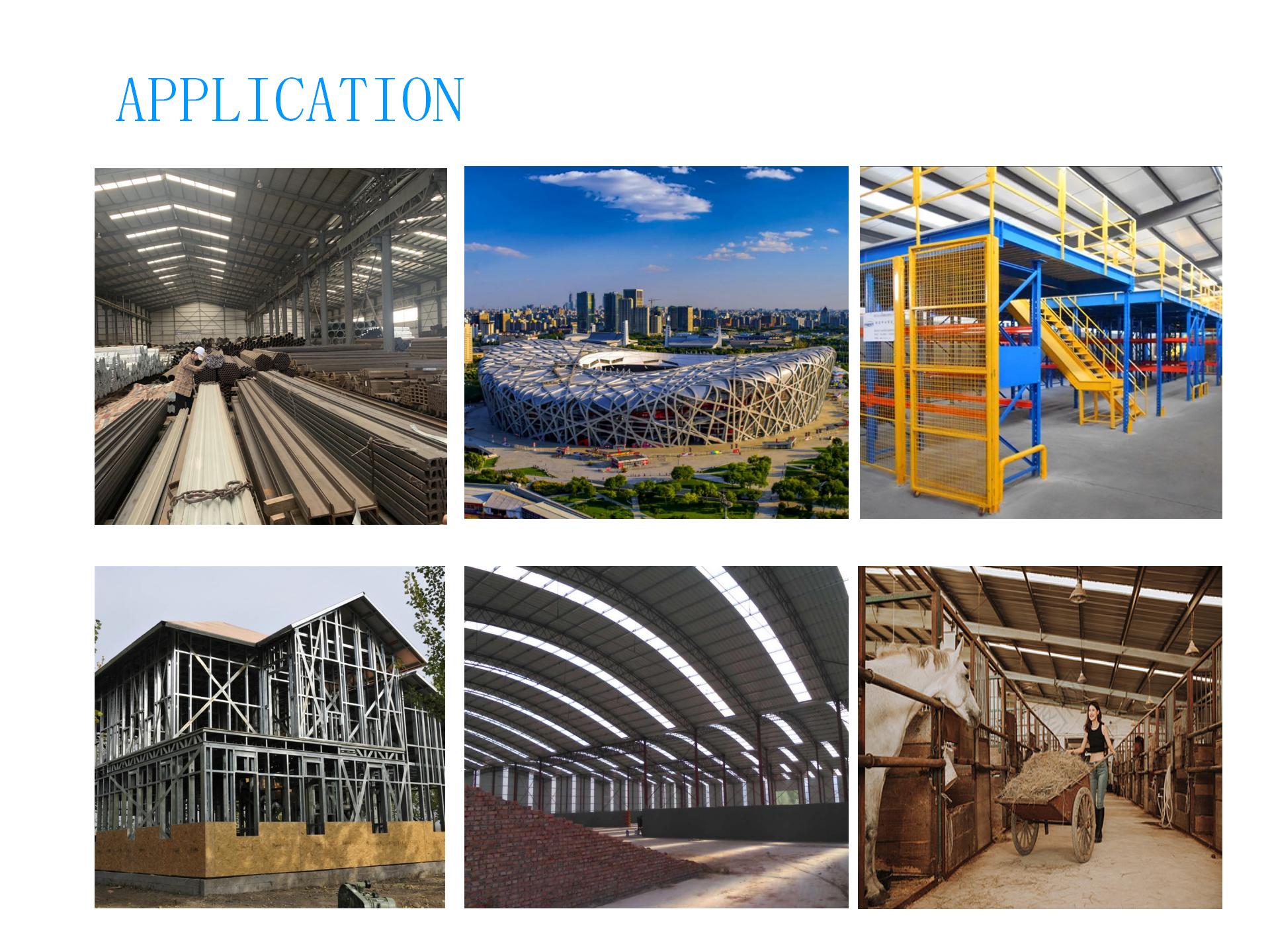

APPLICATION

1.Saving Costs

The steel made buildings present lower production and maintenance cost and 98 % of elements are reusable for new buildings without any loss of strength.

2. Quick installation

The precise machining of steel structural components increases installation speed and allows the use of management software monitoring to speed up construction progress.

3. Health and safety

Warehouse Steel Structure components are produced in the factory and safely constructed on site by professional installation teams. The results of the actual investigation have proved that the steel structure is the safest solution.

There is very little dust and noise during construction because all components are pre-manufactured in the factory.

4. Be flexible

Design Flexibility Steel buildings can be adapted or extended to accommodate new load and space demands, an option not available with other building styles.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Select transport type – Type of transport is either flatbed trucks, containers or ships depending on weight of steel structure, amount, distance, cost and local regulation.

Use Appropriate Lifting Equipment – Use crane, forklift, loader or any other suitable material handling equipment that has sufficient capacity to safely load and unload.

Fasten the Load – Strap or brace steel pieces to keep them from shifting on the road.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1.Benefit from the Scale: We have an extensive supply chain and advanced steel factories, and we can make cost down in manufacturing, purchasing and logistics, and manufacture and service is combined.

2.Series: If you want to know more about the series of steel structure,rail,sheet pile,solar bracket,channel or silicon steel coils,we provide you the whole series of product to meet your project needs.

3.Stable Supply:A stable production line and supply chain can perfectly match with bulk order of steel.

4.Strength of brand: Strong market position and trusted brand.

5.One-stop Solution: Customized manufacturing, production and transportation.

6.Quality Assurance: Good quality and good price.

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT