China Supplier Offers Price Concessions For AllGB Standard Rail Models

The development of GB Standard Steel Rail can be traced back to the early 19th century. Prior to the use of steel, railways were constructed using cast iron rails. However, these rails were prone to cracking and breaking under heavy loads, limiting the efficiency and safety of railway transportation.

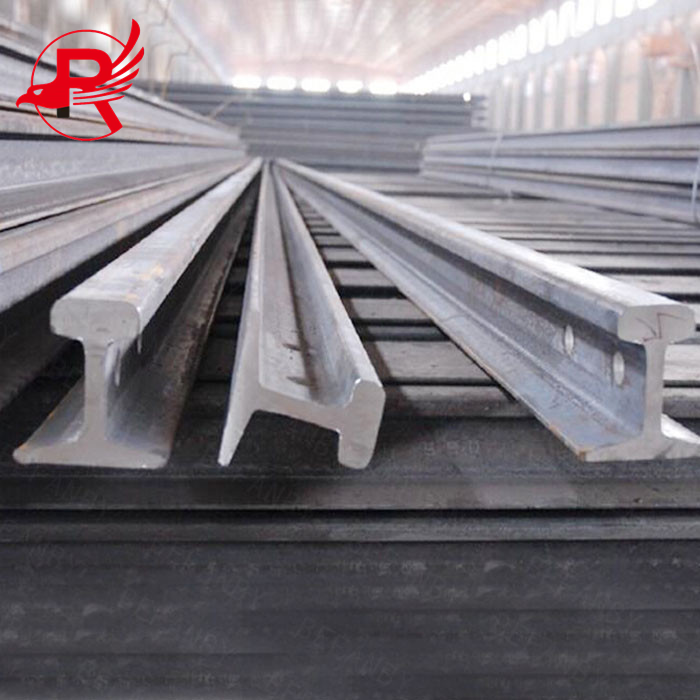

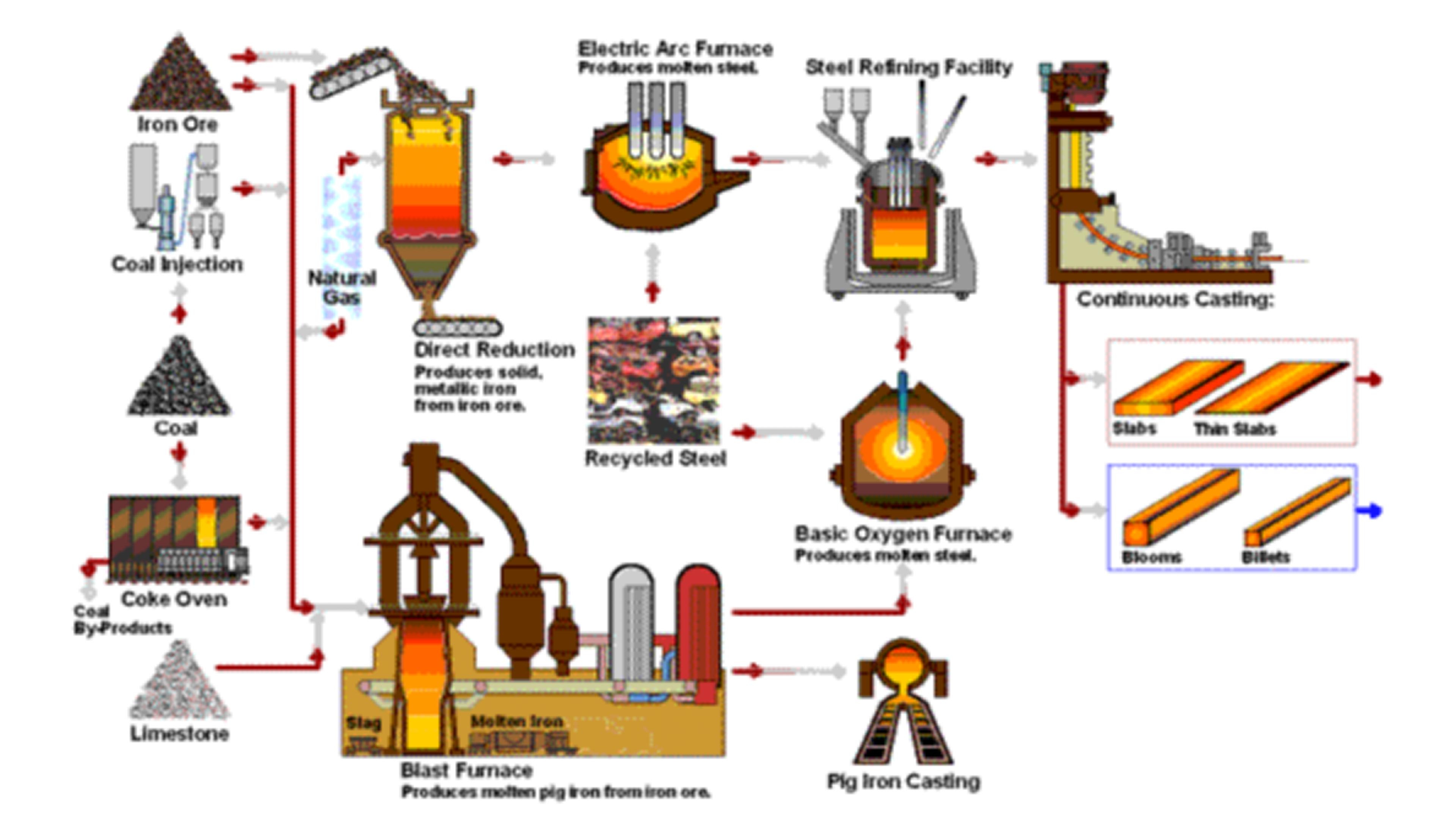

PRODUCT PRODUCTION PROCESS

The transition from cast iron to rail of train occurred gradually over several decades. In the mid-19th century, engineers began experimenting with wrought iron rails, which were more durable and less brittle than cast iron rails. However, wrought iron still had its limitations in terms of strength and durability.

In the 1860s, the Bessemer process was developed, which allowed for mass production of high-quality steel. This process involved blowing air through molten iron to remove impurities and produce steel with superior strength and toughness.

The introduction of steel rails revolutionized railway transportation. Steel rails were able to withstand heavier loads and higher speeds, leading to increased efficiency and capacity in railway systems. With the durability of steel rails, maintenance costs and downtime were greatly reduced, allowing for more reliable and continuous train operations.

Since the introduction of steel rails, there have been ongoing advancements in steel production techniques and rail design. Steel alloys with specific properties, such as high wear resistance and corrosion resistance, have been developed to meet the demands of modern rail transportation.

Today, steel rails continue to be the primary choice for railway construction due to their strength, durability, and cost-effectiveness. They are continuously being improved to meet the ever-increasing demands of the transportation industry.

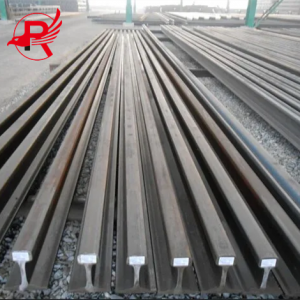

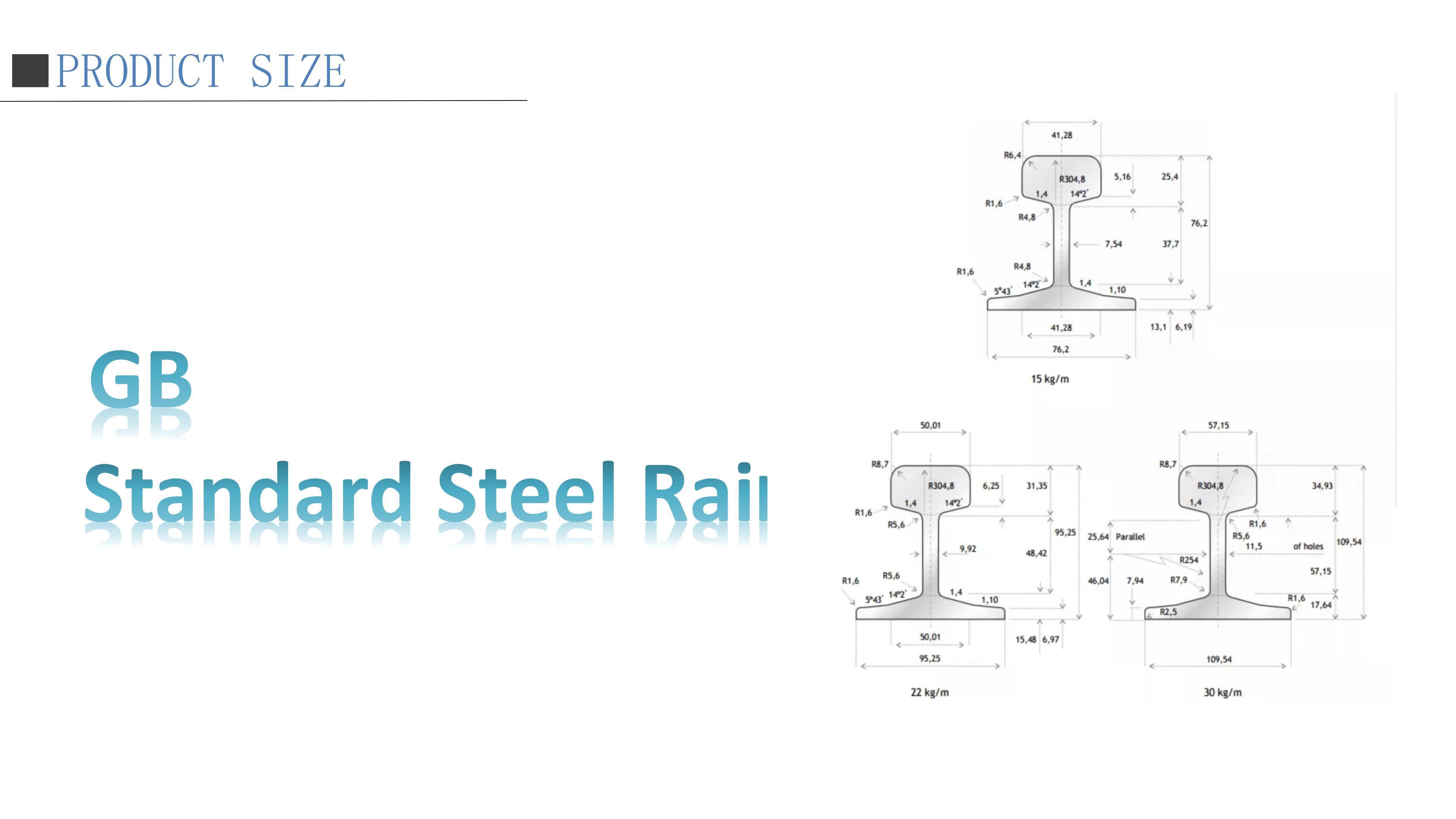

PRODUCT SIZE

|

Product Name:

|

GB Standard Steel Rail | |||

| Type: | Heavy Rail, Crane Rail,Light Rail | |||

| Material/Specification: | ||||

| Light Rail: | Model/Material: | Q235,55Q ; | Specification: | 30kg/m,24kg/m,22kg/m,18kg/m,15kg/m,12 kg/m,8 kg/m. |

| Heavy Rail : | Model/Material: | 45MN,71MN; | Specification: | 50kg/m,43kg/m,38kg/m,33kg/m. |

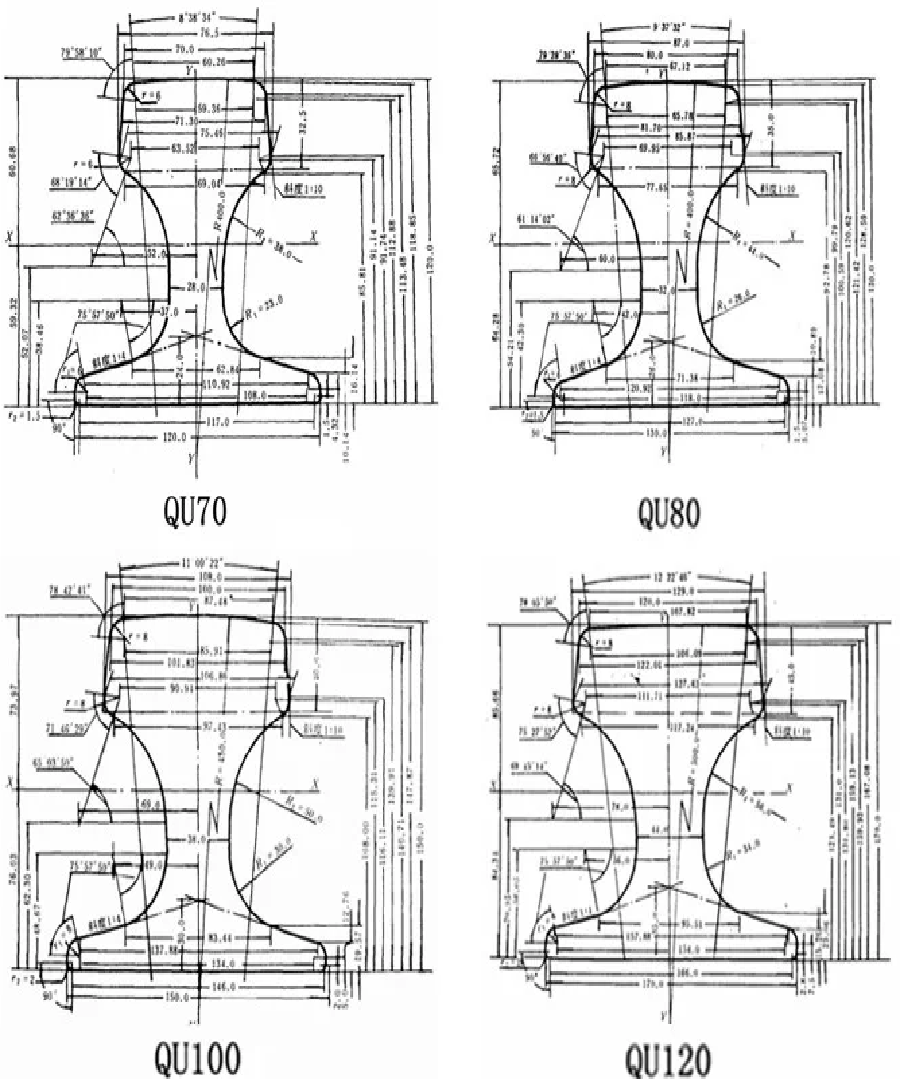

| Crane Rail: | Model/Material: | U71MN; | Specification: | QU70 kg /m ,QU80 kg /m,QU100kg /m,QU120 kg /m. |

GB Standard Steel Rail::

Specifications: GB6kg, 8kg, GB9kg, GB12, GB15kg, 18kg, GB22kg, 24kg, GB30, P38kg, P43kg, P50kg, P60kg, QU70, QU80, QU100, QU120

Standard: GB11264-89 GB2585-2007 YB/T5055-93

Material: U71Mn/50Mn

Length: 6m-12m 12.5m-25m

| Commodity | Grade | Section Size(mm) | ||||

| Rail Height | Base Width | Head Width | Thickness | Weight(kgs) | ||

| Light Rail | 8KG/M | 65.00 | 54.00 | 25.00 | 7.00 | 8.42 |

| 12KG/M | 69.85 | 69.85 | 38.10 | 7.54 | 12.2 | |

| 15KG/M | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

| 18KG/M | 90.00 | 80.00 | 40.00 | 10.00 | 18.06 | |

| 22KG/M | 93.66 | 93.66 | 50.80 | 10.72 | 22.3 | |

| 24KG/M | 107.95 | 92.00 | 51.00 | 10.90 | 24.46 | |

| 30KG/M | 107.95 | 107.95 | 60.33 | 12.30 | 30.10 | |

| Heavy Rail | 38KG/M | 134.00 | 114.00 | 68.00 | 13.00 | 38.733 |

| 43KG/M | 140.00 | 114.00 | 70.00 | 14.50 | 44.653 | |

| 50KG/M | 152.00 | 132.00 | 70.00 | 15.50 | 51.514 | |

| 60KG/M | 176.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| 75KG/M | 192.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| UIC54 | 159.00 | 140.00 | 70.00 | 16.00 | 54.43 | |

| UIC60 | 172.00 | 150.00 | 74.30 | 16.50 | 60.21 | |

| Lifting Rail | QU70 | 120.00 | 120.00 | 70.00 | 28.00 | 52.80 |

| QU80 | 130.00 | 130.00 | 80.00 | 32.00 | 63.69 | |

| QU100 | 150.00 | 150.00 | 100.00 | 38.00 | 88.96 | |

| QU120 | 170.00 | 170.00 | 120.00 | 44.00 | 118.1 | |

ADVANTAGE

The type and strength of rail track are expressed by the approximate mass (kilograms) per meter of length. For example, the current standard rail types in China are 43kg/m, 50kg/m, 60kg/m, 75kg/m, etc. The standard length of rails in China: 43kg/m is 12.5m or 25m; the length of rails above 50kg/m is 25m, 50m, and 100m. Go to the rail welding factory to weld it into a 500m long rail, and then transport it to the construction site and weld it into the required length.

Railroad rail specifications can vary depending on the specific requirements of the railway system and country. However, some common specifications include:

Rail Weight: The weight of a rail is usually expressed in pounds per yard (lbs/yd) or kilograms per meter (kg/m). The rail weight determines the load-carrying capacity and durability of the rail.

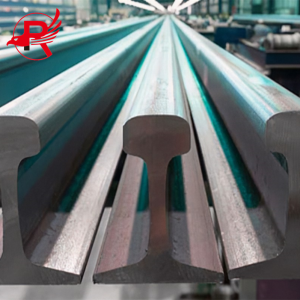

Rail Section: The profile of the rail, also known as the rail section, can vary. Some common rail sections include the I-section (also known as the "I-beam" section), the UIC60 section, and the ASCE 136 section.

Length: The length of a rail can vary depending on the specific railway system, but standard lengths are typically between 20-30 meters.

Standard: Different regions or countries may have specific standards for railroad rails. For example, in North America, the Association of American Railroads (AAR) sets standards for rail specifications.

Steel Grade: The specific grade of steel used in railroad rails can vary. Commonly used steel grades include carbon steel (such as A36 or A709), alloy steel (such as AISI 4340 or ASTM A320), and heat-treated steels (such as ASTM A759).

Wear Resistance: Railroad rails are subjected to continuous wear from the wheels of trains. Therefore, resistance to wear is an important specification for rails. Various coatings or treatments can be applied to the rail surface to improve wear resistance.

Weldability: Rail joints often require welding to connect individual rail sections. Therefore, rail specifications may include criteria for weldability to ensure proper weld strength and durability.

Note: It is important to refer to the specific rail standards used in your region or country for detailed and accurate specifications.

PROJECT

Our company’s rail steel specification 13,800 tons of steel rails exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: chinaroyalsteel@163.com

china rail supplier,china steel rail,GB Standard Steel Rail

APPLICATION

The light Railroad Track Rail is mainly used for laying temporary transportation lines and light locomotive lines in forest areas, mining areas, factories and construction sites. Material: 55Q/Q235B, executive standard: GB11264-89.

1. Railway transportation field

Rails are an essential and important component in railway construction and operation. In railway transportation, steel rails are responsible for supporting and carrying the entire weight of the train, and their quality and performance directly affect the safety and stability of the train. Therefore, rails must have excellent physical and chemical properties such as high strength, wear resistance, and corrosion resistance. At present, the rail standard used by most domestic railway lines is GB/T 699-1999 "High Carbon Structural Steel".

2. Construction engineering field

In addition to the railway field, steel rails are also widely used in construction engineering, such as in the construction of cranes, tower cranes, bridges and underground projects. In these projects, rails are used as footings and fixtures to support and carry weight. Their quality and stability have a vital impact on the safety and stability of the entire construction project.

3. Heavy machinery field

In the field of heavy machinery manufacturing, rails are also a common component, mainly used on runways composed of rails. For example, steelmaking workshops in steel plants, production lines in automobile factories, etc. all need to use runways composed of steel rails to support and carry heavy machines and equipment weighing tens of tons or more.

In short, the wide application of steel rails in transportation, construction engineering, heavy machinery and other fields has made important contributions to the development and progress of these industries. Today, with the continuous innovation and development of technology, rails are constantly updated and upgraded to adapt to the continuous improvement and pursuit of performance and quality in various fields.

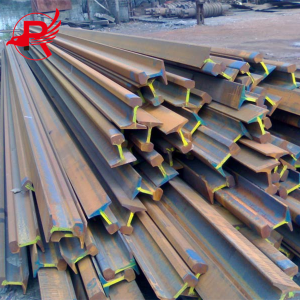

PACKAGING AND SHIPPING

Improving GB Standard Steel Rail head section design is also one of the ways to improve stiffness and wear resistance.

In the rail head section of the early rail, the tread surface is relatively gentle, and the arcs with smaller radius are used on both sides. Until the 1950s and 1960s, it was found that regardless of the shape of the originally designed rail head, after the wear of the train wheels, the shape of the tread on the top of the rail was almost all circular, and the radius of the arc on both sides was relatively large. The experimental simulation found that the peeling of the rail head is related to the excessive wheel-rail contact stress at the inner fillet of the rail head. In order to reduce the damage of rail stripping, all countries have modified the arc design of the rail head to minimize the plastic deformation.

First, countries have followed such a principle in the design of the GB Standard Steel Rail head tread: the arc of the rail top tread conforms to the size of the wheel tread as much as possible, that is, the size of the tread arc, such as the 59.9kg/m rail in the United States, the rail head arc is adopted R254-R31.75-R9.52; the 65kg/m rail of the former Soviet Union, the rail head arc adopts R300-R80-R15; the UIC 60kg/m rail, the rail head arc adopts R300-R80-R13. It can be seen from the above that the main feature of the section design of the modern rail head is the use of complex curves and three radii. On the side of the rail head, a straight line with a narrow top and a wide bottom is adopted, and the slope of the straight line is generally 1:20~1:40. A straight line with a large slope is often used at the lower jaw of the rail head, and the slope is generally 1:3 to 1:4.

Second, in the transition zone between the GB Standard Steel Railhead and the rail waist, in order to reduce the cracks caused by stress concentration and increase the frictional resistance between the fishplate and the rail, a complex curve is also used in the transition area between the rail head and the rail waist, and a large radius design is adopted in the waist. For example, UIC's 60kg/m rail uses R7-R35-R120 in the transition zone between the rail head and the waist. Japan's 60kg/m rail uses R19-R19-R500 in the transition zone between the rail head and the waist.

Third, in the transition zone between the rail waist and the rail bottom, in order to achieve a smooth transition of the section, a complex curve design is also adopted, and the gradual transition is smoothly connected with the slope of the rail bottom. Such as UIC60kg/m rail, is to use R120-R35-R7. Japan's 60kg/m rail uses R500-R19. China's 60kg/m rail uses R400-R20.

Fourth, the bottom of the rail bottom is all flat, so that the section has good stability. The end faces of the rail bottom are all at right angles, and then rounded with a small radius, usually R4~R2. The inner side of the rail bottom is usually designed with two sets of oblique lines, some of which adopt double slope, and some adopt single slope. For example, UIC60kg/m rail adopts 1:275+1:14 double slope. Japan's 60kg/m rail adopts 1:4 single slope. China's 60kg/m rail adopts 1:3+1:9 double slope.

PRODUCT CONSTRUCTION

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.