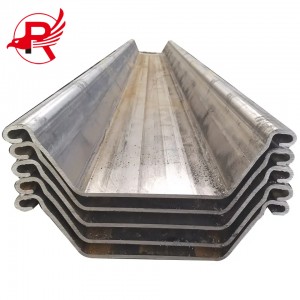

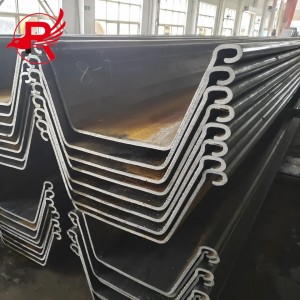

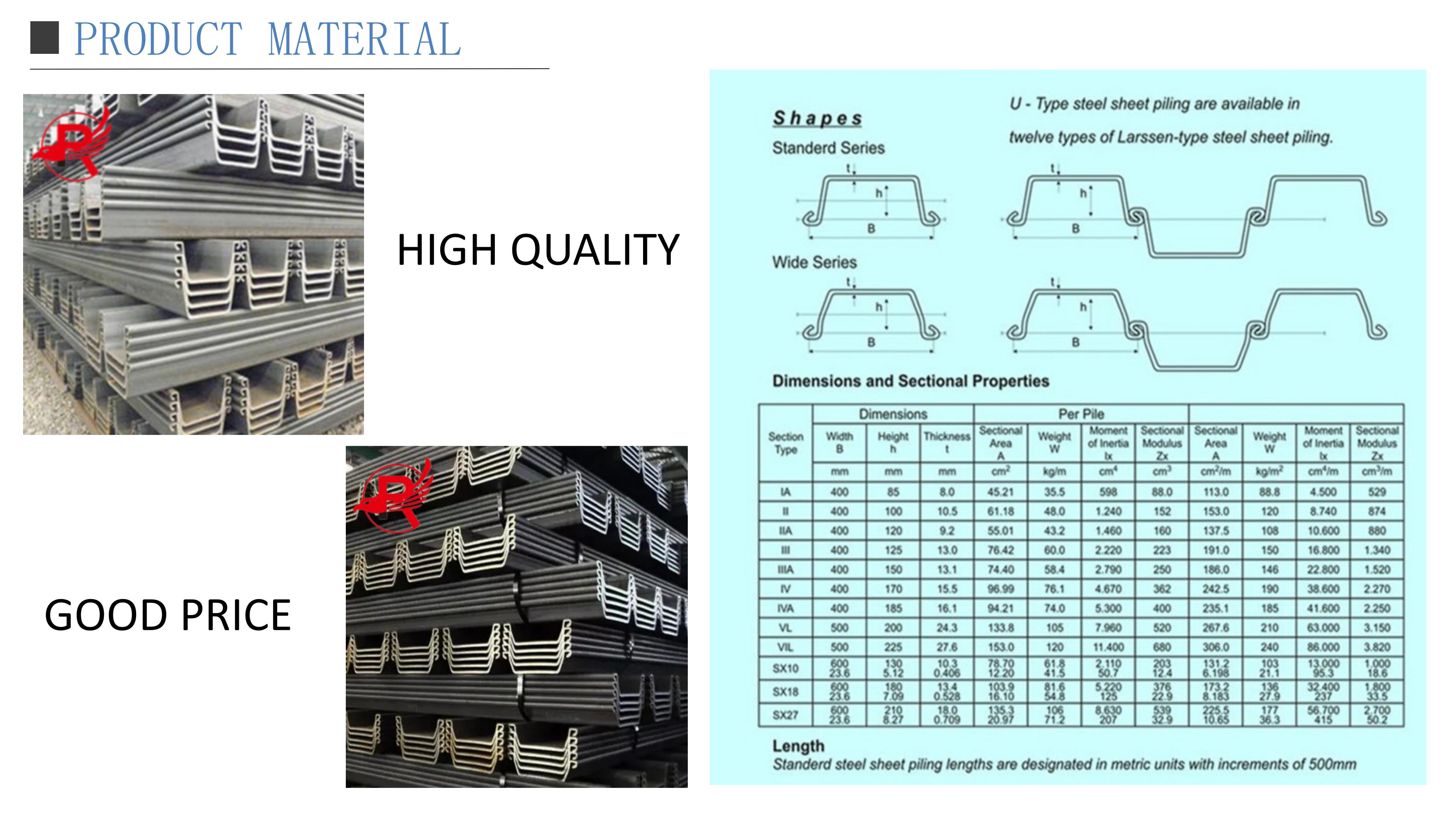

Metal Building Material Hot Rolled U Type Steel Sheet Pile Type 2 Type 3 Steel Plate For Sheet Pile

PRODUCT SIZE

|

roduct Name

|

|

|

Standard

|

AiSi, ASTM, DIN, GB, JISEN10249,EN10248,JIS A 5523 and JIS A 5528,ASTM A328 / ASTM A328M

|

|

Length

|

9 12 15 20 m as required Max.24m

|

|

Width

|

400-750mm as required

|

|

Thickness

|

6-25mm

|

|

Material

|

Q234B/Q345B JIS A5523/SYW295,JISA5528/SY295,SYW390,SY390 ect.

|

|

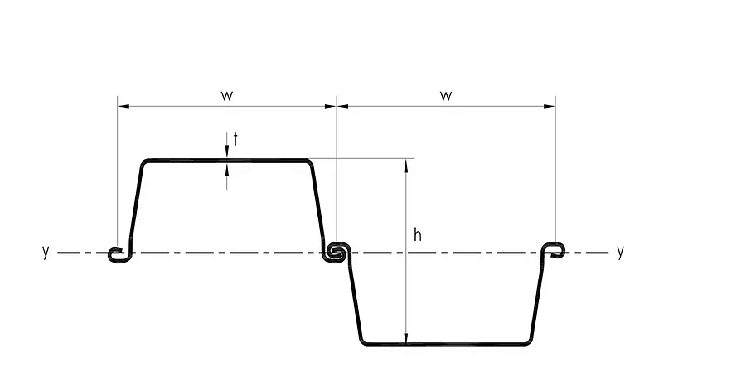

Shape

|

U,Z,L,S,Pan,Flat,hat profiles

|

|

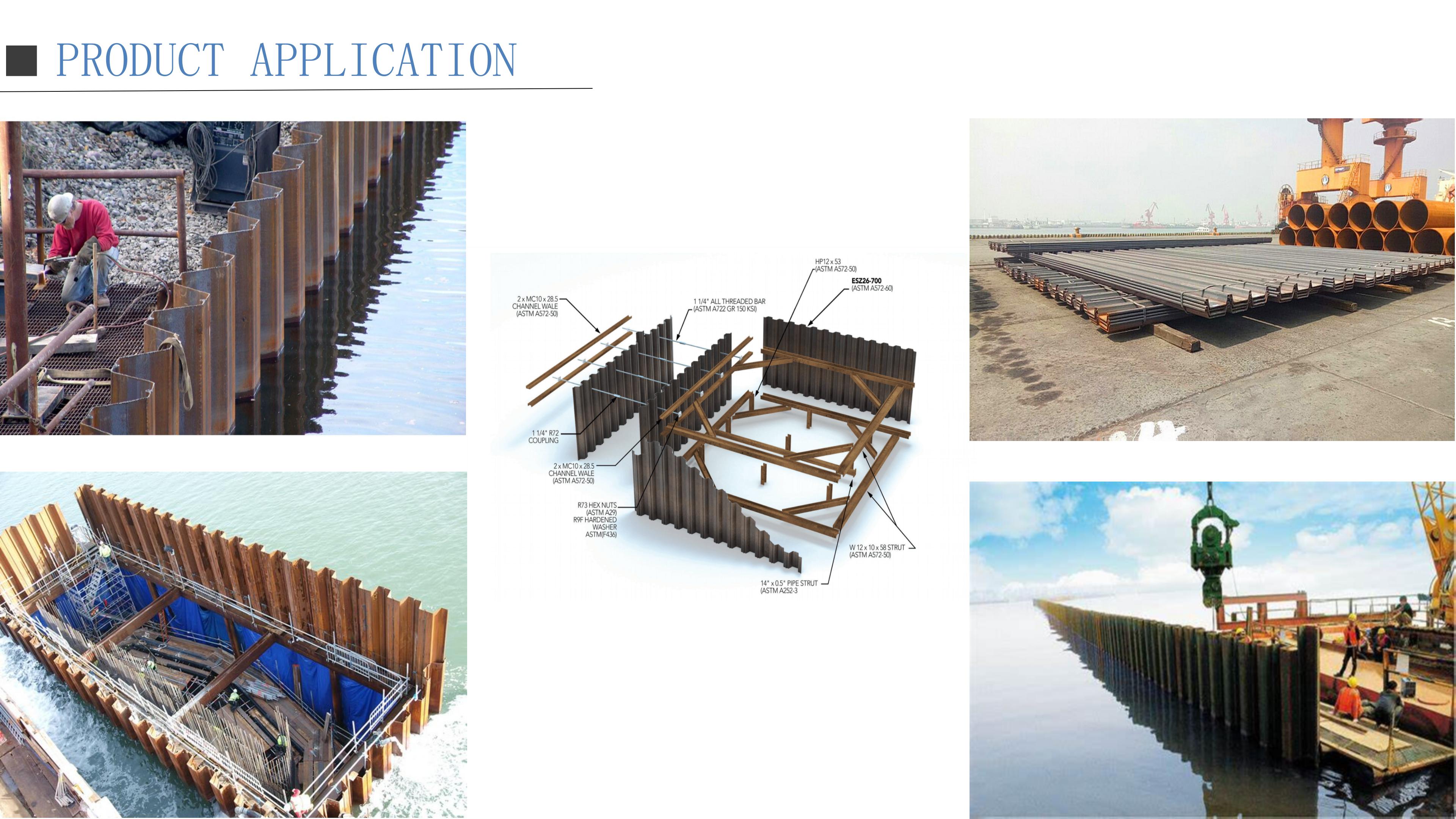

Application

|

Cofferdam /River flood diversion and control/

Water treatment system fence/Flood protection Wall/ Protective embankment/Coastal berm/Tunnel cuts and tunnel bunkers/ Breakwater/Weir Wall/ Fixed slope/ Baffle wall |

|

Steel grade

|

SGCC/SGCD/SGCE/DX51D/DX52D/S250GD/S280GD/S350GD/G550/SPCC

S275,S355,S390,S430,SY295,SY390,Grade50,Grade55,Grade60,A690 |

|

Technique

|

Cold formed interlock or clutches

|

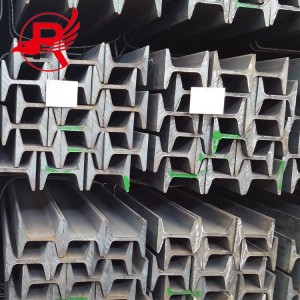

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

APPLICATION

Type 2 Sheet Piles: Features and Applications:

500 x 200 u sheet pile are known for their high modulus of elasticity, which allows for efficient and stable retaining structures. These sheet piles are commonly used in projects involving the construction of permanent structures, as they can withstand high bending moments and provide excellent soil retention. In addition, their interlocking design facilitates quick and easy installation, making them a preferred choice for time-sensitive projects.

S355GP sheet pile are particularly suitable for constructing deep excavation walls, cut-off walls against groundwater, basement walls, and bridge abutments. Their versatility and flexibility make them ideal for various construction scenarios, ensuring safe and reliable structures.

Type 3 Sheet Piles: Characteristics and Applications:

Type 3 sheet piles are renowned for their exceptional driving performance, making them suitable for challenging environments. These sheet piles have a higher tensile strength than Type 2, allowing them to withstand heavy loads and impacts. The Type 3 sheet piles feature a wider profile, enhancing their overall performance and stability in challenging soil conditions.

Type 3 sheet piles are commonly used in marine and coastal projects, such as seawalls, breakwaters, and port infrastructure. Their enhanced durability and resistance to corrosion make them a reliable choice for projects exposed to harsh environmental conditions. Additionally, Type 3 sheet piles are often preferred in projects requiring temporary retention systems due to their ease of extraction.

Benefits and Advantages of foundation piles:

1 Time and Cost-Effective: Hot rolled U type steel sheet piles are manufactured with consistent quality and are readily available in various sizes and lengths. This availability ensures easy procurement and efficient construction timelines, saving valuable time and resources.

2 Versatility: These sheet piles are highly versatile and can adapt to various construction needs, be it temporary or permanent structures. They can be used as continuous walls, cofferdams, or cutoff walls, providing flexibility in design and ensuring stability.

3 Environmentally Friendly: Hot rolled U type steel sheet piles are often made from recycled materials, making them a sustainable choice for construction projects. Additionally, the durability and longevity of these sheet piles reduce the need for frequent replacements, reducing overall environmental impact.

4 Strong and Durable: The hot rolling process imparts high strength and durability to U type steel sheet piles, allowing them to withstand heavy loads and offer exceptional reliability. They possess excellent structural integrity and can resist the forces exerted by soil, water, and other environmental factors.

5 Cost-Effective Maintenance: Once installed, hot rolled U type steel sheet piles require minimal maintenance throughout their service life. Their resistance to corrosion and general wear ensures long-term cost-effectiveness.

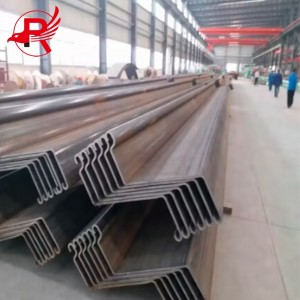

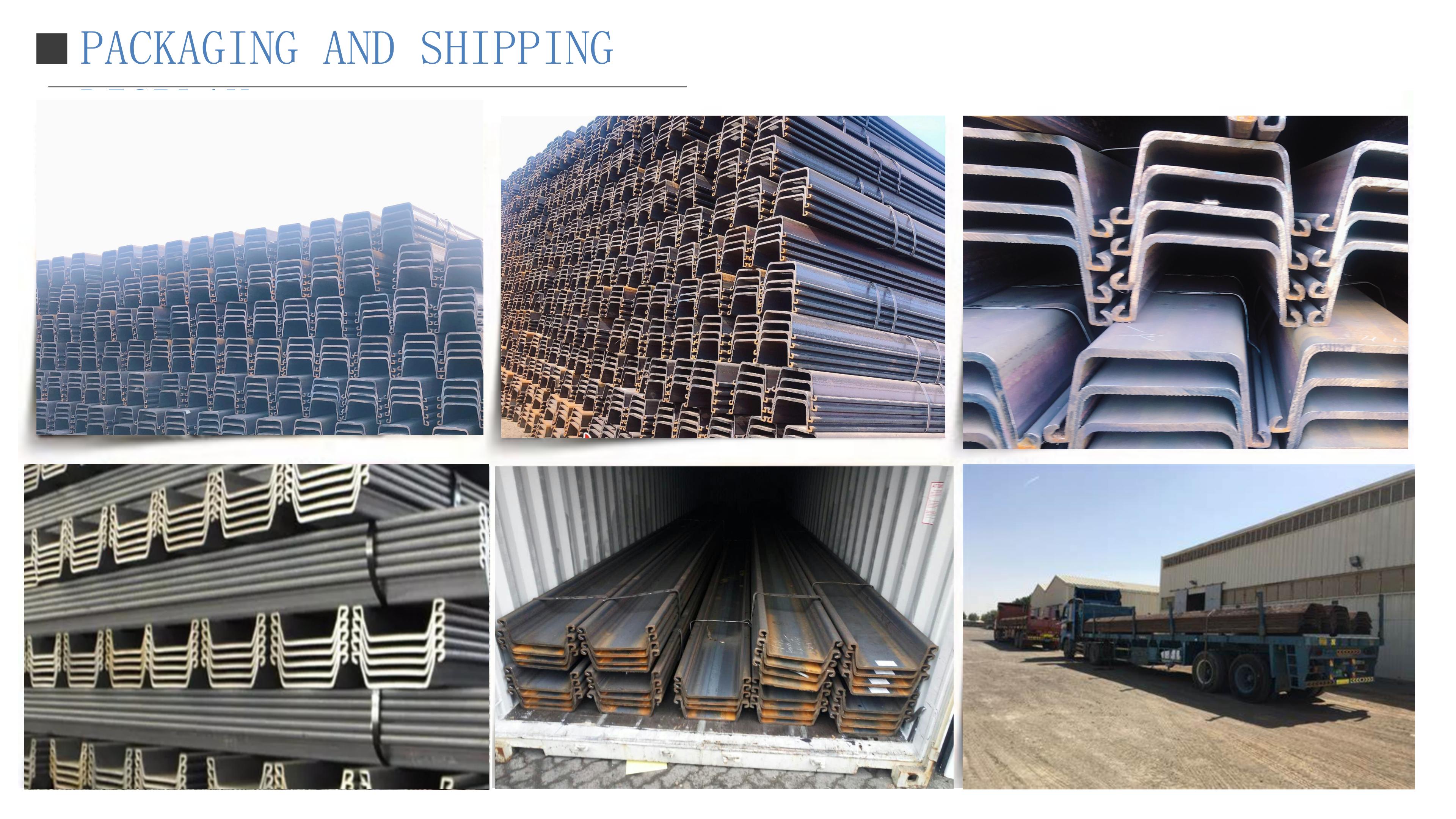

PACKAGING AND SHIPPING

The packaging and shipping method for metal sheet pile typically involve the following steps:

Packaging: The steel sheet piles are usually bundled together into packages using steel straps or wires. The bundles are secured to prevent shifting or damage during transportation.

Labeling: Each package is labeled with relevant information such as the product name, size, quantity, and destination address. This helps with identification and tracking during shipping.

Protection: To protect the steel sheet piles from moisture and physical damage, they are often wrapped with waterproof or moisture-resistant materials such as plastic or tarps. This helps prevent rust and other forms of corrosion.

Loading: The packaged pile sheeting are loaded onto trucks or shipping containers using appropriate lifting equipment. Care should be taken during loading to ensure proper weight distribution and prevent any damage to the products or the vehicle/container.

Transportation: The choice of transportation method depends on various factors such as destination, quantity, and urgency. Steel sheet piles can be transported by road, rail, or sea. For long-distance or international shipping, sea freight is commonly used.

Shipping Documentation: All necessary shipping documents, including bill of lading, packing list, commercial invoice, and any specific certifications or compliance documents, should be prepared and included with the shipment.

It is important to adhere to relevant packaging standards and shipping regulations to ensure the safe and timely delivery of the hot rolled U type steel sheet pile to its destination. Consulting with a professional logistics or shipping company can help ensure proper packaging and shipping methods are followed.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

When a customer wishes to visit a product, the following steps can usually be arranged:

Make an appointment to visit: Customers can contact the manufacturer or sales representative in advance to make an appointment for the time and place to visit the product.

Arrange a guided tour: Arrange professionals or sales representatives as tour guides to show customers the production process, technology and quality control process of the product.

Display products: During the visit, show products at different stages to customers so that customers can understand the production process and quality standards of the products.

Answer questions: During the visit, customers may have various questions, and the tour guide or sales representative should answer them patiently and provide relevant technical and quality information.

Provide samples: If possible, product samples can be provided to customers so that customers can more intuitively understand the quality and characteristics of the product.

Follow-up: After the visit, promptly follow up on customer feedback and needs to provide customers with further support and services.

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4:What is the advantage about your company?

A4:Our company has professional team and professional production line.

Q5: The logo and the color can be customized?

A5: Yes, we welcome you to sample custom

Q6: Any other good service your company can provide?

A6:Yes,we can provide good after-sale and fast delivery.