China Factory Price SGCC Z90 Z120 Z180 Dx51d GI Sheet Galvanized Steel Sheets

Product Detail

Galvanized sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective rust prevention method that is often used, and about half of the world's zinc production is used in this process.

According to the production and processing methods, it can be divided into the following categories:

Hot-dip galvanized steel sheet. Dip the thin steel plate into the molten zinc tank to make the thin steel plate with a layer of zinc adhered to its surface. At present, the continuous galvanizing process is mainly used for production, that is, the coiled steel plate is continuously immersed in a galvanizing tank with molten zinc to make a galvanized steel plate;

Alloy galvanized steel. This type of steel is also produced using the hot-dip galvanizing method, but is immediately heated to approximately 500°C after exiting the tank to form a zinc-iron alloy film. This type of galvanized steel exhibits excellent paint adhesion and weldability.

Electrogalvanized steel. Galvanized steel produced using the electroplating method offers excellent workability, but the coating is thinner and its corrosion resistance is inferior to that of hot-dip galvanized steel.

Main Application

Features

1. Corrosion-resistant, easy to paint, form, and spot weld.

2. Widely used, primarily in small appliance components requiring aesthetics. However, it is more expensive than SECC, leading many manufacturers to switch to SECC to save costs.

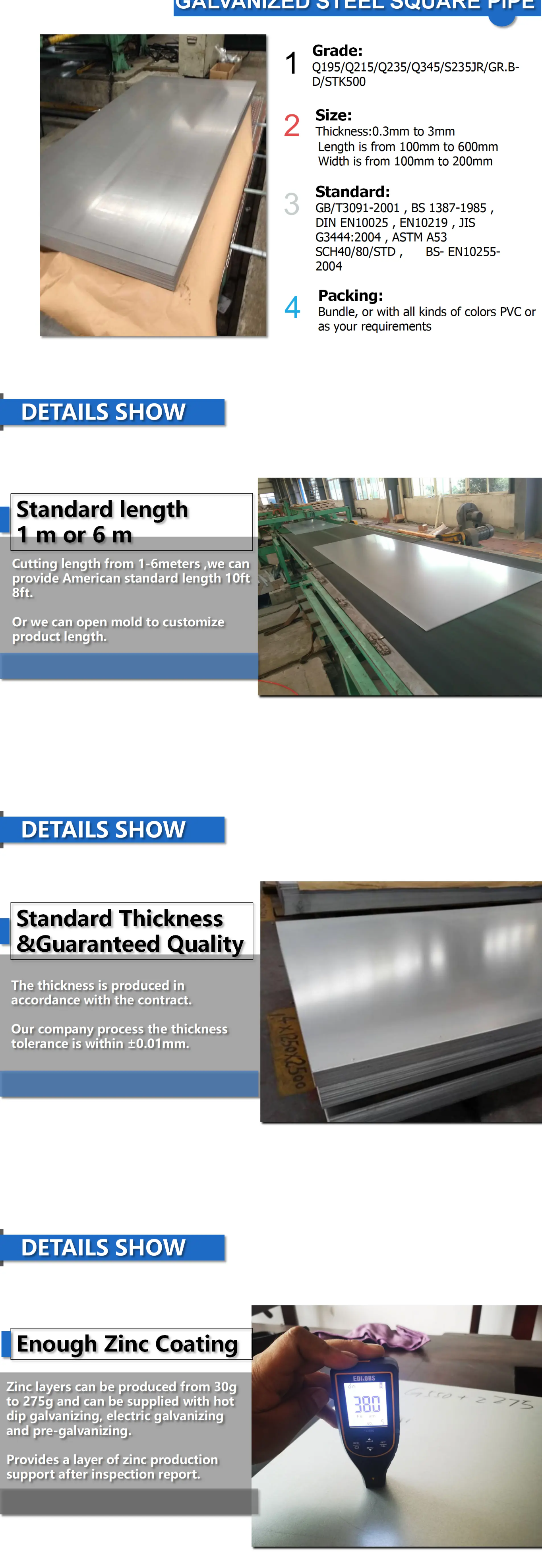

3. Classification by zinc layer: The size of the zinc flakes and the thickness of the zinc layer reflect the quality of the galvanizing process; the smaller the flakes, the thicker the zinc layer, the better. Manufacturers may also add an anti-fingerprint treatment. Additionally, grades can be differentiated by coating; for example, Z12 indicates a total coating thickness of 120g/mm on both sides.

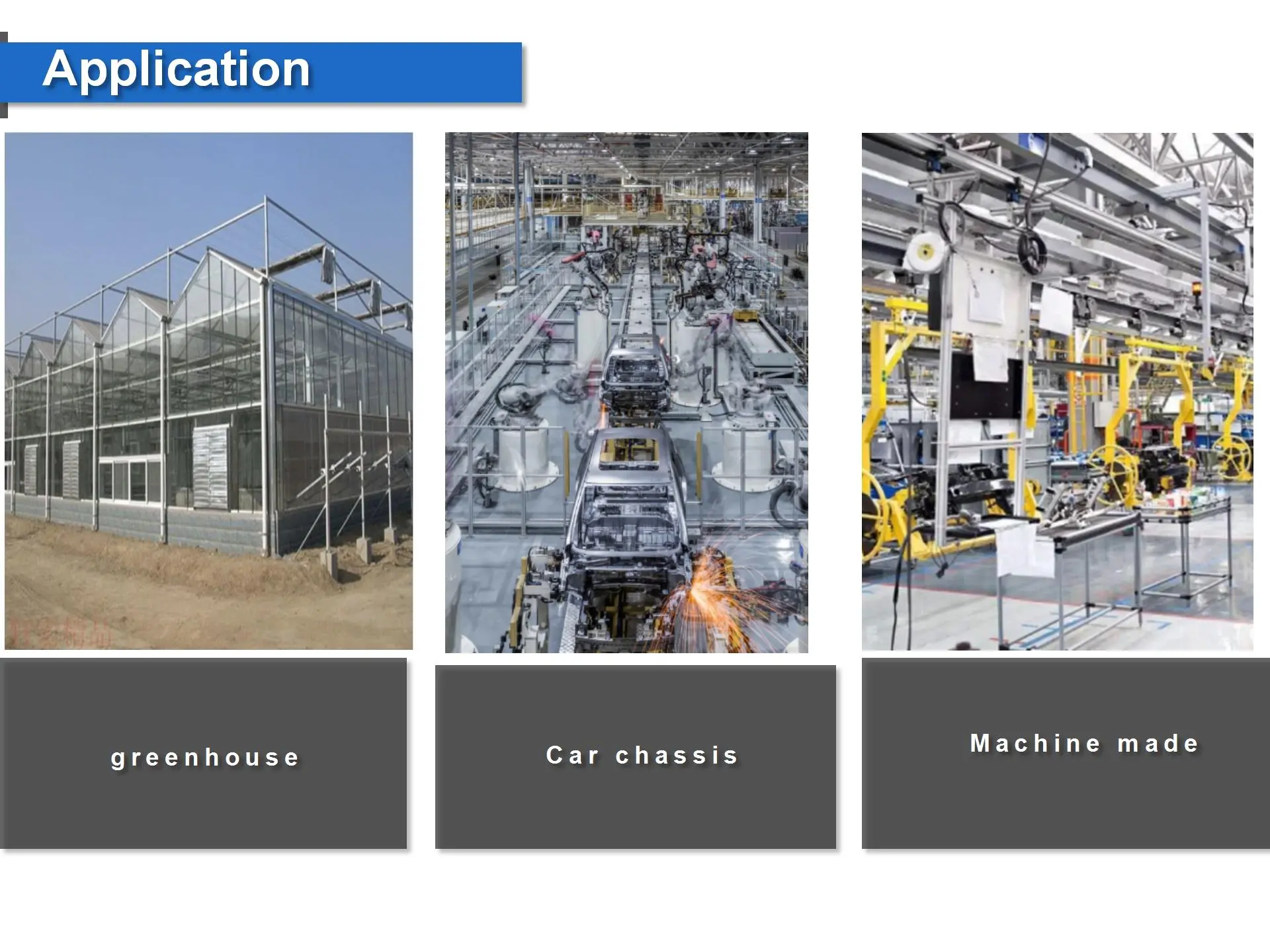

Application

Galvanized steel sheet and strip products are primarily used in the construction, light industry, automotive, agriculture, animal husbandry, fishery, and commercial sectors.

Roofing and wall materials: Galvanized steel sheet offers excellent weather resistance, resisting rain, snow, UV rays, and other natural factors. It is commonly processed into corrugated steel sheet and pre-painted galvanized steel sheet (a color coating applied over the zinc coating).

Steel structural components: In building steel structures (such as purlins, braces, and keels), galvanized steel sheet can be formed into various profiles through cold bending.

Municipal infrastructure: Galvanized steel sheet is used in the manufacture of municipal infrastructure such as light poles, traffic signs, guardrails, and trash cans. These products are exposed to the elements for extended periods of time, and a galvanized coating effectively prevents corrosion caused by rain, dust, and other factors, thereby reducing maintenance costs.

Automobile body components: Galvanized sheet (especially hot-dip galvanized sheet) is widely used in automotive body panels (such as doors and hood linings), chassis components, and floor panels due to its excellent weldability and corrosion

Parameters

| Technical Standard | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Steel Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

| Thickness | customer's requirement |

| Width | according to customer's requirement |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

| Zinc Coating | 30-275g/m2 |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

| Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

| Quality | Approved by SGS,ISO |

| ID | 508mm/610mm |

| Coil Weight | 3-20 metric ton per coil |

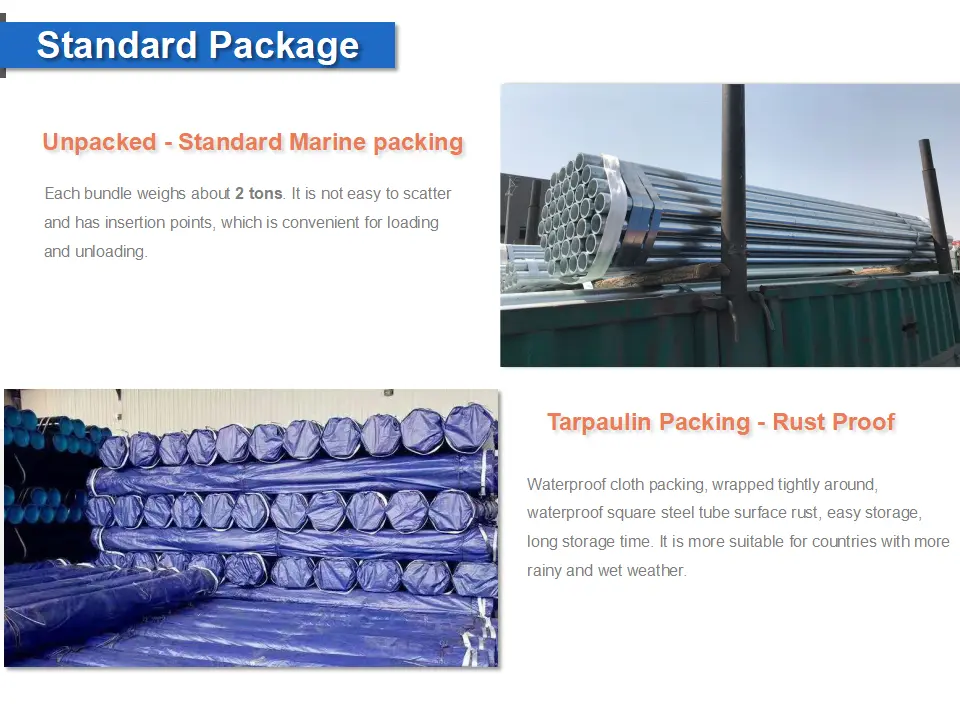

| Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

| Export market |

Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc

|

Delivery

FAQ

Q: Are u a manufacturer?

A: Yes, we are spiral steel tube manufacturer locates in Tianjin city, China

Q: Can I have a trial order only several tons?

A: Of course. We can ship the cargo for u with LCL serivece.(Less container load)

Q: If sample free?

A: Sample free, but the buyer pays for the freight.

Q: Are you gold supplier and do trade assurance?

A: We seven years gold supplier and accept trade assurance.