Click to get a FREE 3D Design and Quote within 24 hours!

Custom Industrial Steel Structure Solutions Supplier Prefabricated Steel Structures

APPLICATION

Warehouses and Logistics Centers: Prefabricated steel sructure buildings enable rapid, economical construction of warehouses and distribution centers. Modular components permit rapid construction while providing structural integrity and durability.

Industrial factories and plat production:High load-bearing industrial processes are supported by robust steel frameworks, such as H-beam, I-beam, steel plate. These are well-suited for equipment platforms, production lines and factory floors.

Bridges and Infrastructure Projects: Steel construction is prevalent in the building of bridges, highways, and energy infrastructure because it can meet complex engineering requirements with strength, accuracy and flexibility.

Commercial and public buildings: Prefabricated steel frames offer a modern and flexible solution for commercial construction, such as for office buildings, shopping centres and sports halls.

PRODUCT DETAIL

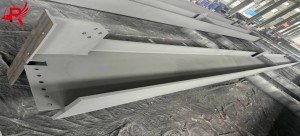

Core steel structure products for factory construction

1. Main load-bearing structure (adaptable to tropical seismic requirements)

| Product Type | Specification Range | Core Function | Central America Adaptation |

|---|---|---|---|

| Portal Frame Beam | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Primary load-bearing beam for roof and wall systems | Seismic-grade bolted connections; lightweight structural optimization for easier inland transportation |

| Steel Column | H300×300 ~ H500×500 (ASTM A36) | Main vertical support for floors and structural frames | Seismic-resistant connectors; hot-dip galvanized coating (Zn ≥ 85 μm) for high-humidity environments |

| Crane Beam | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Designed for overhead crane systems (5–20 tons capacity) | High-strength design with shear plate end connections; optimized structural weight reduction for cost efficiency |

2. Enclosure system products (weatherproof + anti-corrosion)

Roof Purlins

C12×20 to C16×31 sections, hot-dip galvanized finish, with spacing of 1.5–2.0 meters.

Designed to support color-coated steel roofing panels and engineered to withstand typhoon wind speeds up to Level 12.

Wall Purlins

Z10×20 to Z14×26 profiles with anti-corrosion coating (salt spray resistance exceeding 1000 hours).

Integrated ventilation openings to reduce internal condensation, making them suitable for tropical factory environments.

Bracing & Support System

Galvanized round steel bars (Φ12–Φ16) and angle steel (L50×5) used for structural bracing.

Enhanced lateral stability to resist hurricane-level wind loads and improve overall frame rigidity.

3. Supporting auxiliary products (localized construction adaptation)

Precast Part: Hot-dipped galvanized steel plate (thickness 10–20 mm) for concrete footing, for sale in Costa Rica and for import in other Central American countries.

Bolts: High strength bolts (galvanized, grade 8.8) are used in place of welding in field, minimizing the assembly time.

Fire & Corrosion Protection: Water based intumescent coating (≥1.5 h fire protection), UV stable acrylic anti-corrosive coating (≥10 years service life), following local environmental protocols.

STEEL STRUCTURE PROCESSING

Cutting

-

CNC plasma and flame cutting for thick steel plates

-

Precision shearing machines for thin plates

-

Ensures accurate dimensions and smooth cutting edges

Forming

-

Cold bending and press brake processing for purlins, gutters, and trims

-

Rolling machines for circular members and round supports

-

Maintains structural consistency and dimensional accuracy

Welding

-

Submerged arc welding for H-beams and heavy columns

-

Manual arc welding for connection plates and structural joints

-

CO₂ gas-shielded welding for thin sections

-

Strict welding inspection to ensure structural integrity

Hole Processing

-

CNC drilling for precise bolt hole alignment

-

Punching machines for small-batch components

-

High positional accuracy for easy site installation

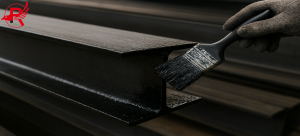

Surface Treatment

-

Shot blasting or sand blasting for rust removal

-

Weld seam grinding and surface finishing

-

Hot-dip galvanizing for bolts and supporting components to improve corrosion resistance

Trial Assembly

-

Pre-assembly of columns, beams, and bracing systems

-

Dimensional verification using professional measuring tools

-

Dismantling after inspection for safe shipment

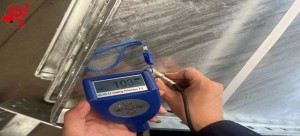

STEEL STRUCTURE TESTING

| Test Type | Standard(s) | Purpose / Notes |

|---|---|---|

| Salt Spray Test | ASTM B117, ISO 11997-1 | Corrosion resistance for Central American coastal conditions |

| Adhesion Test | ISO 2409 / ASTM D3359 (crosshatch), ISO 4624 / ASTM D4541 (pull-off) | Control coating adhesion and peel strength |

| Humidity & Heat Resistance | ASTM D2247 (40°C / 95% RH) | Prevent blistering and cracking in rainy conditions |

| UV Aging Test | ASTM G154 | Protect against UV-induced fading and chalking |

| Film Thickness Test | ASTM D7091 (dry), ASTM D1212 (wet) | Ensure coating thickness meets corrosion protection requirements |

| Impact Strength Test | ASTM D2794 (drop hammer) | Protect coating during transport and storage |

SURFACE TREATMENT

PACKAGING AND SHIPPING

Structural Steel Components

-

Carefully packed with surface protection materials to prevent scratches and coating damage

-

Reinforced with stabilizing supports to maintain structural integrity during handling and transportation

Small Accessories & Fasteners

-

Packed in durable wooden crates

-

Protected with waterproof wrapping, plastic covers, or anti-rust paper

-

Ensures corrosion prevention during long-distance shipping

Identification & Labeling

-

Clear labeling on all boxes and bundles

-

Marked with component codes and project references

-

Facilitates safe unloading and efficient on-site installation

WHY CHOOSE OUR STEEL STRUCTURES?

Clear Span Design: Maximize your internal workspace with unobstructed layouts (up to 30m+ without interior columns).

Low Maintenance: Our hot-dip galvanizing process ensures maximum protection against rust and corrosion in harsh environments.

Turnkey Solution: From initial 3D CAD drawings to shipping and installation guidance, we provide a seamless one-stop service.

Eco-Friendly: Steel is 100% recyclable, making it the preferred choice for modern green construction.

FAQ

Q1: What are the standards of your products in terms of quality?

A1: We comply with standards of ASTM, EN, AS/NZS, JIS.Ancillary Materials with MTC.

Q2: Can you manufacture products for high corrosive environment?

A2: Yes. We offer a variety of coatings, including hot-dipped galvanizing (HDG) and coatings that pass the ASTM B117 Salt Spray Test for marine use.

Q3: Do you have samples

A3: Yes,We provide free samples for the regular profiles,courier Fee will be refunded against order in bulk.

Q4: What’s packing of the product?

A4: Our packing is seaworthy(strapping, anti-rust oil, steel pallets) and We want to make sure the goods would reach you in good condition.

Q5: What’s your payment term?

A5: Our payment is T/T (30% deposit) or 100% L/C at sight.

Q6: Do you accept third-party inspection?

A6: Yes, we partner with SGS, BV, or TUV for your preshipment inspection.

Ready to start your project?

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506