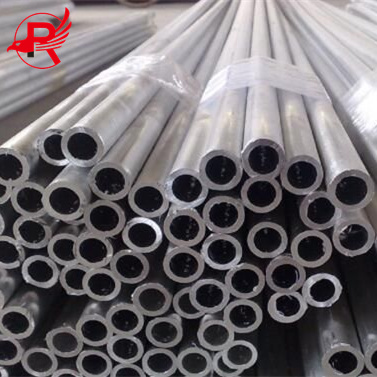

Customized 2024 3003 6082 7005 7075 Extrusion Aluminum Seamless Aluminum Tube Pipe for industry

Product Detail

Facts of Aluminium Pipe

Material: Made of aluminum material, types of 6xxx, 5xxx, 3xxx series alloys are available to improve the strength, corrosion resistance, or other features.

Size and Tolerance:We can offer different sizesODIDThickness, with strict tolerance for uniform size.

Surface Finish: smooth; untreated, polished, anodized or coated with other finishes for decoration and protection against corrosion.

Mechanical Properties: Depending on aluminum alloy and temper, these include ultimate tensile strength, yield strength, elongation and hardness.

Chemical composition: Aluminum with alloying elements such as magnesium, manganese, copper, or zinc as per standards or based on customer's needs.

Corrosion Resistance: Natural oxide film and alloy element protect material in various media.

Joining Methods: Depending on the size, alloy and application, it can be welded, brazed, or joined with mechanical fittings (steel adapter flanges and the like).

For exact specifications, please refer to industry standards or inquire supplier datasheets to determine the appropriate alloy, size and finish.

SPECIFICATIONS FOR ALUMINUM PIPES

|

Aluminum Tube/Pipe

|

||

|

Standard

|

ASTM, ASME, EN, JIS, DIN, GB

|

|

|

Specifcation for round pipe |

OD

|

3-300 mm,or customized

|

|

WT

|

0.3-60 mm,or customized

|

|

|

Length

|

1-12m,or customized

|

|

|

Specification for square pipe

|

SIZE

|

7X7mm- 150X150 mm,or customized

|

|

WT

|

1-40mm,or customized

|

|

|

Length

|

1-12m,or customized

|

|

| Material Grade |

1000 series: 1050, 1060, 1070, 1080, 1100, 1435, etc

2000 series: 2011, 2014, 2017, 2024, etc 3000 series: 3002, 3003, 3104, 3204, 3030, etc 5000 series: 5005, 5025, 5040, 5056, 5083, etc 6000 series: 6101, 6003, 6061, 6063, 6020, 6201, 6262, 6082, etc 7000 series: 7003, 7005, 7050, 7075, etc |

|

|

Surface treatment

|

Mill finished, anodized, powder coating, Sand blast, etc

|

|

|

Surface colors

|

Nature, silver, bronze, champagne, black, gloden or as customized

|

|

|

Usage

|

Auto /doors/decoration/construction/curtain wall

|

|

|

Packing

|

Protective film+plastic film or EPE+kraft paper,or customized

|

|

SPECIFIC APPLICATION

Uses of Aluminum Tubing

HVAC Systems: Channels for coolant or refrigerant, taking advantage of good thermal conductivity.

Plumbing: Lightweight and corrosion resistant tubing for water, gas, or waste in homes.

Transportation: Radiators, air intake, turbocharger and exhaust systems used for weight reduction and efficient heat transfer.

Industrial Applications: Liquid or gas transporting in chemical, oil & gas, pharmaceutical, food & beverage and wastewater applications.

Solar: Piping for solar water heating systems for heat transfer.

Construction & architecture: Load-bearing walls, balconies, curtain walls and façades made to be resilient, provide design flexibility.

Electrical Use: High Conductivity Alloys are utilized for wiring, power transmission and busbars.

Furniture and Interior Design: Lightweight pipes that can be tailored to suit chairs, tables, shelving and hanging rods.

Packaging & Shipping

Guideline for Packaging and Delivery of Aluminum Pipe

Corner Protectors Sturdy cardboard tubes or boxes on the dimension of the pipes in a way that they will not move during the packing.

Cushioning: Line the box with bubble wrap or foam padding to protect the contents during shipping.

Ends Sealed: Pipe ends should be capped or taped to reduce shifting.

Labeling: Clearly label the packages with "Fragile" or "Handle with Care."

Packing: Prevent dust and strong tape sealing.

Stacking Multiple Pipes: Stack two or more pipes vertically in the same direction so the body of one pipe will rest between the flutes on the pipes below so as to prevent rolling motion and to distribute the weight of the pipes evenly.

Trustworthy Delivery: Go for the carriers who are well-versed with delicate or sensitive products.