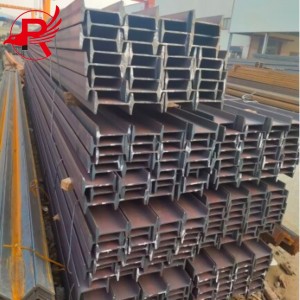

EN Standard Size H Beam Steel HEA HEB IPE 150×150 H beam Price

PRODUCT PRODUCTION PROCESS

These designations signify different types of IPE beams based on their dimensions and properties:

- HEA (IPN) beams: These IPE beams have exceptionally wide flange widths and flange thicknesses, making them suitable for heavy-duty structural applications.

- HEB (IPB) beams: These are IPE beams with a medium flange width and flange thickness, commonly used in construction for various structural purposes.

- HEM beams: These are IPE beams with a particularly deep and narrow flange, providing increased strength and load-carrying capacity.

These beams are engineered to offer certain structural benefits and the selection of which one to use is determined by the needs of a specific building job.

PRODUCT SIZE

| Designation | Unt Weight kg/m) |

Standard Secional imension mm |

Sectional Ama (cm² |

|||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Designatio | Unit Weight kg/m) |

Standad Sectional Dimersion (mm) |

Sectiona Area (cm²) |

|||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

EN H-Shaped Steel

Grade: EN10034:1997 EN10163-3:2004

Specification:HEA HEB and HEM

Standard: EN

FEATURES

HEA, HEB, and HEM beams are European standard IPE (I-beam) sections used in construction and structural engineering. Here are some of the key features of each type:

HEA (IPN) beams:

Wide flange width and flange thickness

Suitable for heavy-duty structural applications

Provides good load-carrying capacity and bending resistance

HEB (IPB) beams:

Medium flange width and flange thickness

Versatile and commonly used in construction for various structural purposes

Offers a balance of strength and weight

HEM beams:

Includes a deep, narrow flange for added strength and loadability. Designed for demanding work and high load applications. Chosen to satisfy certain structural requirements of the building based on the purpose the building is designed for and the loads the walls are expected to carry.

PRODUCT INSPECTION

Inspection Standards for H-Beam:

Visual inspection: Surface should be clean and smooth, without any defect such as dent, scratch or rust.

Dimensions: Length, width, height, web thickness and flange thickness shall comply with the standards and the requirements of order.

Bend & Twist: The parallelism and verticality of the bent ends should satisfy the requirement of the standards, gauge to be used for measurement if required.

Weight: Dual in specification and order.

Chemical Composition: It is needed for welding or processing.. The composition should conform to the specifications.

Mechanical Properties: The tensile strength, the yield point, and the elongation shall satisfy the requirements of the standards.

NDT: Beperformed to guarantee the internal quality, NDT when so specified.

Packing & Marking: Should be in line with the norms for the proper transportation and storage.

APPLICATION

Application of HEA, HEB, HEM Beams:

Building construction with application to the floors, Roof and load bearing elements in commercial and industrial buildings.

Bridges & Infrastructure: For structural support in bridges, tunnels, airports and power plants.

Industrial Buildings: Warehouses and storage buildings, factories.

Structural framing: They form the frame of large buildings, supporting walls and cladding.

Equipment Support: Heavy industrial machines and equipment.

In summary: The strength, versatility and extreme load bearing capacity of HEA, HEB and HEM beams enables the contemporary engineer to design and construct with so much confidence and ease.

PACKAGING AND SHIPPING

Packaging and Protection:

Packaging is crucial to maintaining the quality of H Shaped Steel Beam during transportation and storage. Steel should be securely strapped with high-strength strapping or tying to prevent movement and potential damage. Additionally, measures should be taken to protect the steel from moisture, dust, and other environmental factors. Wrapping the bundles with weather-resistant materials, such as plastic or tarpaulin, helps prevent corrosion and rust.

Loading and Securing for Transport:

Care should be taken when loading and securing packaged steel onto the transport vehicle. Using appropriate lifting equipment, such as a forklift or crane, ensures safe and efficient handling. Steel should be evenly distributed and properly aligned to prevent any structural damage during transport. After loading, secure the cargo with appropriate restraints, such as ropes or chains, to ensure stability and prevent shifting.

FAQ

1. How can I get a quotation?

Leave us a message, and we will respond promptly.

2. Will you deliver on time?

Yes. We ensure high-quality products and timely delivery—honesty is our core principle.

3. Can I get samples before ordering?

Yes. Samples are usually free and can be made from your sample or technical drawings.

4. What are your payment terms?

Typically 30% deposit with the balance against B/L. Terms: EXW, FOB, CFR, CIF.

5. Do you accept third-party inspection?

Yes, absolutely.

6. How can I trust your company?

We are an experienced steel supplier with headquarters in Tianjin. You are welcome to verify our credentials in any way.