Europen Steel Structure Accessories EN 10025-2 S355JR Steel Grating

Product Detail

| Property | Details |

|---|---|

| Material | EN 10025-2 S355JR Structural Steel |

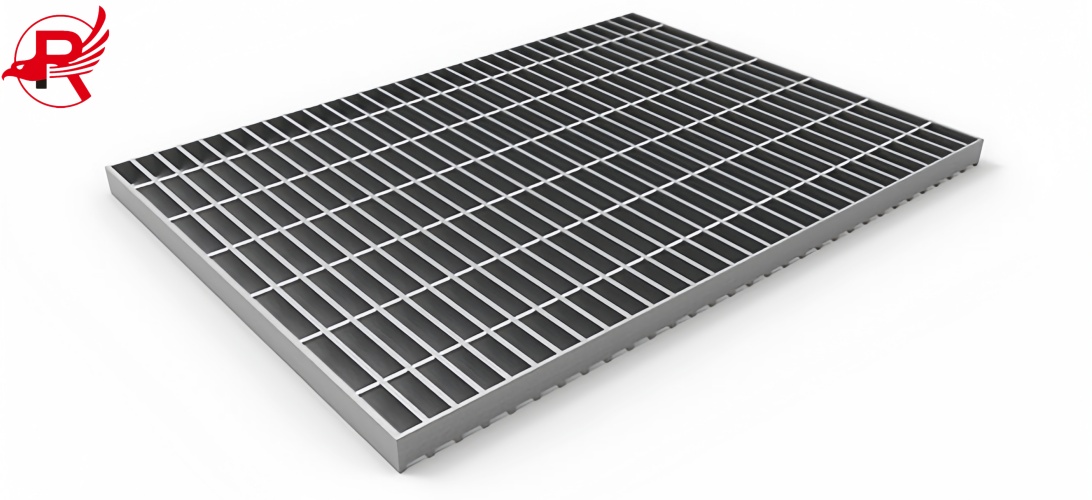

| Type | Flat Bar Grating, Heavy-Duty Grating, Press-Locked Grating, Custom Fabricated Galvanized Grating |

| Load Bearing Capacity | Customizable based on bearing bar spacing and thickness; available in Light, Medium, Heavy, Extra Heavy duty |

| Mesh / Opening Size | Common sizes: 25 mm × 25 mm, 30 mm × 30 mm, 40 mm × 40 mm; can be customized |

| Corrosion Resistance | Depends on surface treatment; hot-dip galvanized, painted, or powder-coated for enhanced protection |

| Installation Method | Fixed with support bars or bolted; suitable for flooring, platforms, stair treads, walkways |

| Applications / Environment | Industrial plants, warehouses, factory platforms, stair treads, pedestrian bridges, outdoor walkways, drainage areas |

| Weight | Varies depending on grating size, bearing bar thickness, and spacing; calculated per square meter |

| Customization | Supports custom dimensions, mesh openings, surface finishes, load-bearing specifications, and galvanized fabrication |

| Quality Certification | ISO 9001 Certified |

| Payment Terms | T/T: 30% Advance + 70% Balance |

| Delivery Time | 7–15 Days |

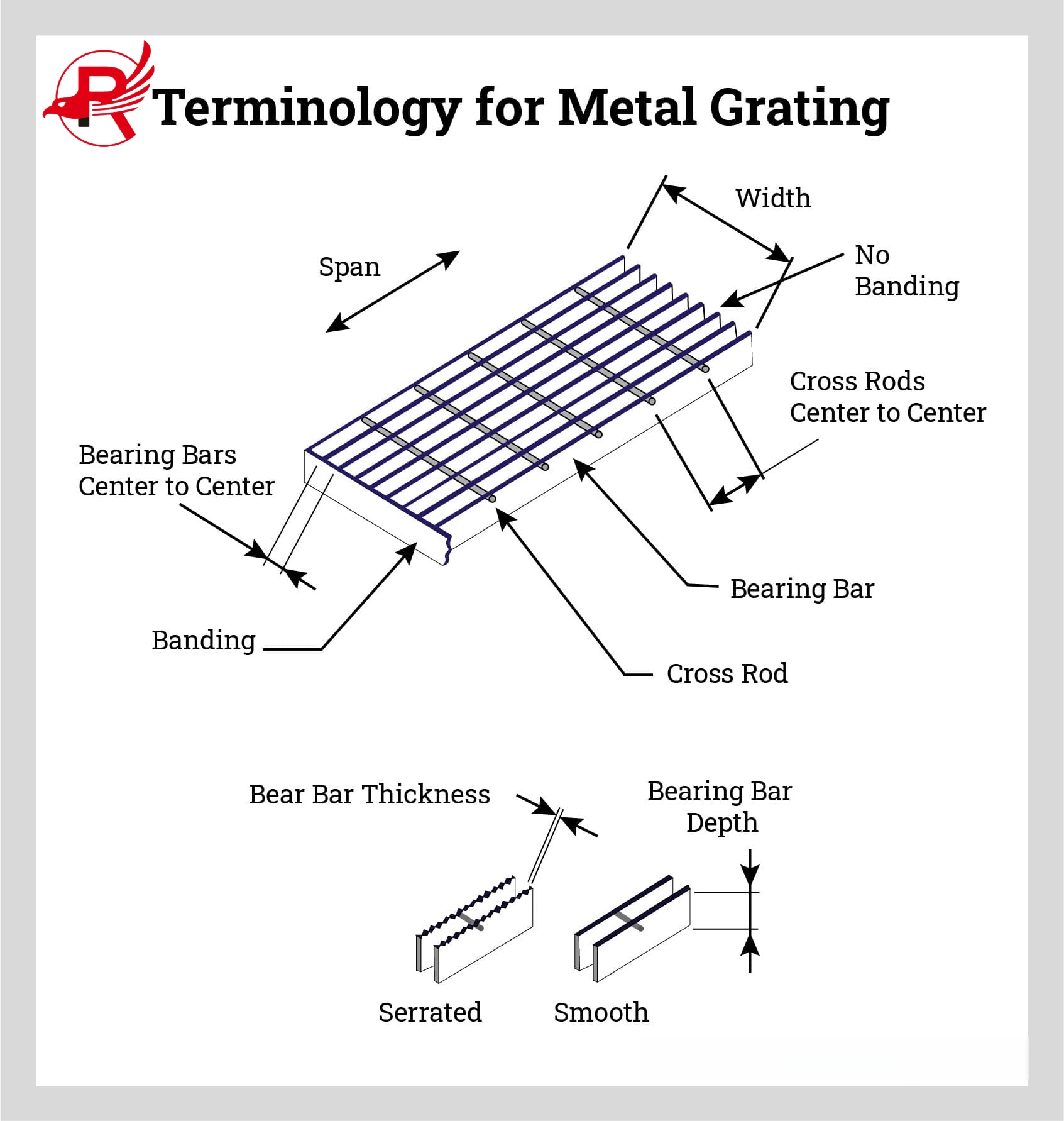

EN 10025-2 S355JR Steel Grating Size

| Grating Type | Bearing Bar Pitch / Spacing | Bar Width | Bar Thickness | Cross Bar Pitch | Mesh / Opening Size | Load Capacity |

|---|---|---|---|---|---|---|

| Light Duty | 20 mm – 25 mm | 20 mm | 4–6 mm | 30–50 mm | 25 × 25 mm | Up to 350 kg/m² |

| Medium Duty | 25 mm – 38 mm | 20 mm | 5–8 mm | 30–50 mm | 30 × 30 mm | Up to 700 kg/m² |

| Heavy Duty | 38 mm – 50 mm | 20 mm | 6–10 mm | 30–50 mm | 40 × 40 mm | Up to 1400 kg/m² |

| Extra Heavy Duty | 50 mm – 76 mm | 20 mm | 8–12 mm | 30–50 mm | 50 × 50 mm | >1400 kg/m² |

EN 10025-2 S355JR Steel Grating Customized Content

| Customization | Options | Description / Range |

|---|---|---|

| Dimensions | Length, Width, Bearing Bar Spacing | Length: 1–6 m; Width: 500–1500 mm; Bearing bar spacing: 25–100 mm depending on project load requirements |

| Load Capacity | Light, Medium, Heavy, Extra Heavy Duty | Designed to satisfy specific structural and safety needs for various industrial and commercial applications |

| Processing | Cutting, Drilling, Welding, Edge Treatment | Panels can be cut, drilled, welded, or have edges reinforced to facilitate installation |

| Surface | Hot-dip Galvanizing, Powder Coating, Industrial Paint, Anti-slip | Surface treatments chosen for indoor, outdoor, or coastal environments to enhance corrosion protection and safety |

| Marking & Packaging | Labels, Project Codes, Export-ready | Custom labeling and secure packaging for transport, project identification, and traceability |

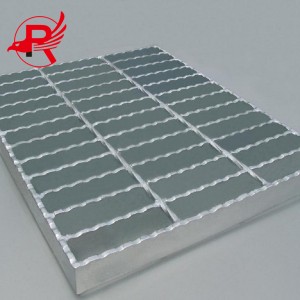

| Special Features | Anti-slip Serration, Custom Mesh | Optional serrated or patterned surfaces for improved safety and aesthetics; part of China Grid Steel Diversiform Grating solutions |

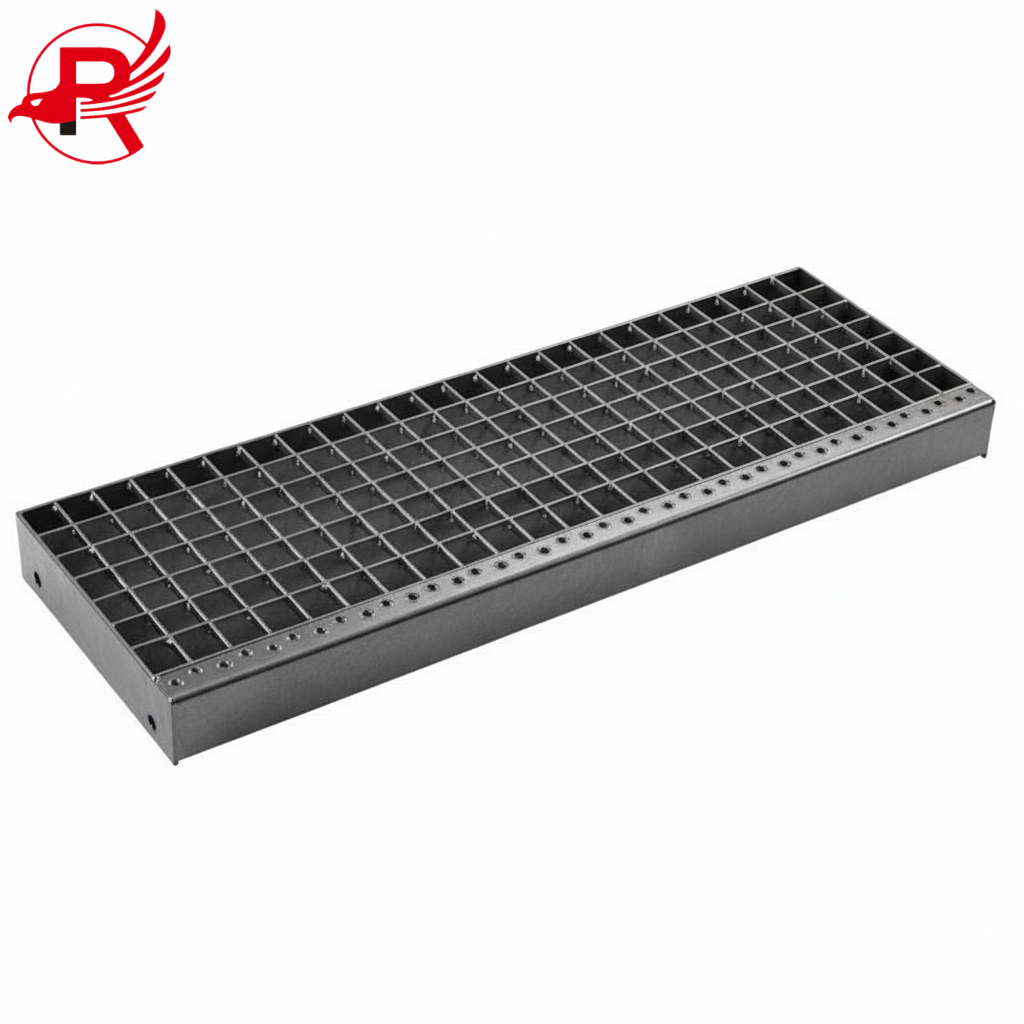

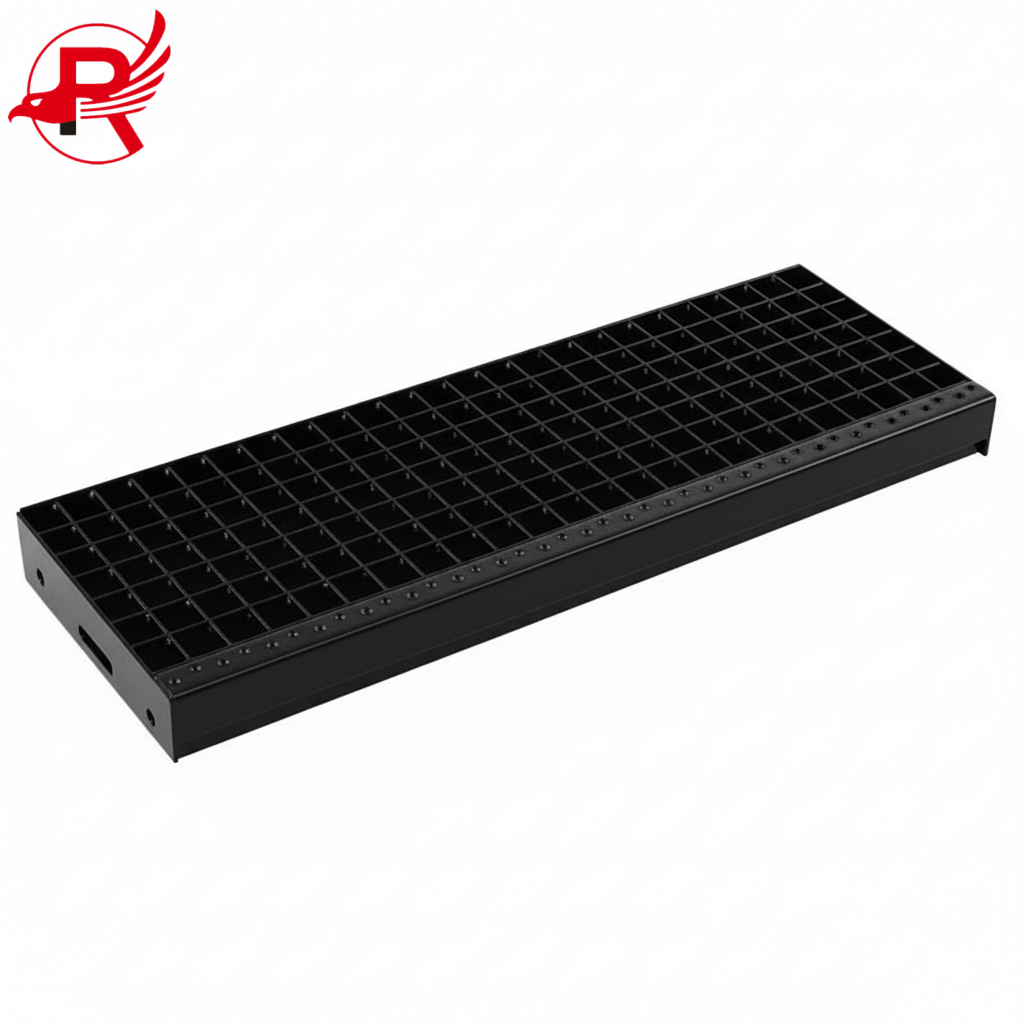

Surface Finish

Initial Surface

Galvanized Surface

Painted Surface

Application

1.Sidewalks

Offers a safe, non-slip surface for use in the industrial and commercial environments. The open-grid pattern of China Steel Grating allows liquids, dirt and dust to flow through the walkway remain in clean and safe.

2.Steel Stairs

Suitable for industrial and commercial stairs. The surface of China Steel Grating can be serrated or decrusted to provide better security and grip.

3.Platforms to Work

Offers a firm standing ground for work at height. Good ventilation, visibility and easy cleaning are made possible by the open-grid construction.

4.Drainage Areas

Allows drain water, oil or other liquids to drain with ease. Generally on basements outdoors corridors drainage covers and work areas together with China Steel Grating.

Our Advantages

Durable & Long-Lasting

Fabricated from EN 10025-2 S235JR structural steel, the China Grid Steel Diversform Grating possesses good loading and long service life.

Customizable Options

Length, width, bearing bar, mesh type, surface treatment and loading can all be customized.

Corrosion & Weather Resistant

For inside and outside maritime applications. Surface treatment: Dipped hot galvanized, powder coating, industrial painting.

Safe & Slip-Resistant

The water and debris pass through the grids with an open-grid design that features good drainage and ventilation along with reduced potential of slipping.

Wide Range of Applications

Perfect for industrial or commercial applications such as walkways, stair treads, work platforms, and drainage.

Reliable Quality

Made of S235JR Steel - Trusted . ISO 9001 certified to ensure constant quality.

Fast Delivery & Support

Smooth project execution is guaranteed with efficient production, safe packaging & delivery in 7-15 days, professional after-sales service.

Packaging & Shipping

Packing

Standard Export Packaging: Panels are securely bundled and reinforced to prevent damage during transportation.

Custom Labels & Project Codes: Bundles can be labeled with material grade, dimensions, and project information for easy identification and tracking.

Protection: Optional covers or wooden pallets are available for long-distance shipping or fragile surfaces.

Delivery

Lead Time: Approximately 15 days per unit; faster delivery possible for bulk orders.

Shipping Methods: Shipped via container, flatbed, or local truck.

Safety: Packaging is designed to ensure safe handling, transportation, and installation on site.

FAQ

Q1: What is the material?

A: It is constructed of heavy duty durable material, the high-strength ASTM A572 steel which is the best quality steel for load-bearing and durable rolling door slat in the market.

Q2: Can it be customized?

A: Yes, we customize size, mesh, bearing bar spacing, surface finish, load capacity according to your project specifications.

Q3: What surface treatments do you offer?

A: Hot-dip galvanizing, powder coating, or industrial paint for indoor/outdoor/coastal environments.

Q4: Typical applications?

A: Perfect for walkways, stair treads, work platforms, and floor drain applications in industrial or commercial environments.

Q5: How is it packed and shipped?

A: Panels are securely bundled, palletized optional, labeled with material and project information, and shipped by container, flat rack or local transportation.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506