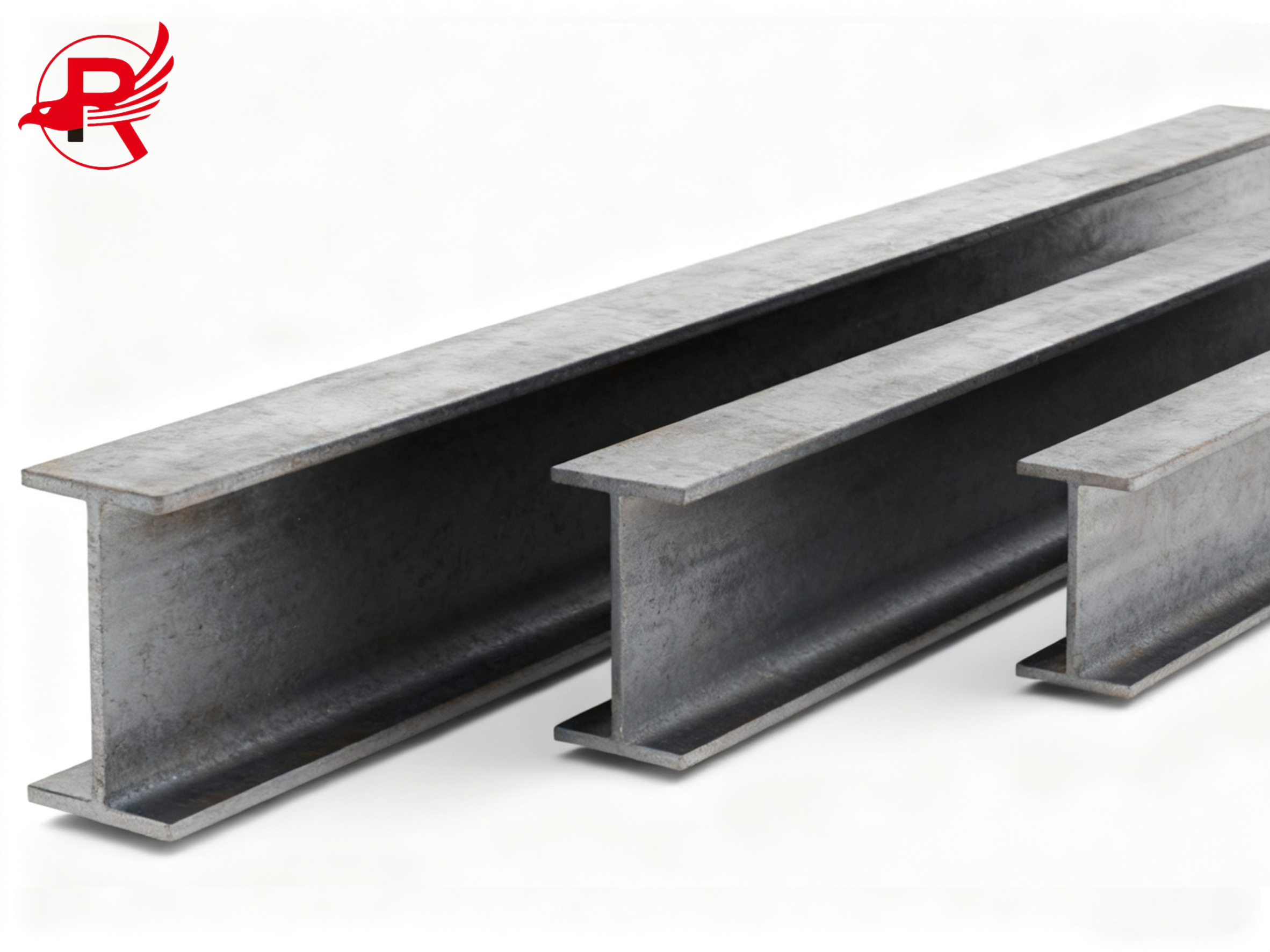

HEA & HEB European Standard Beams | High-Strength S235 / S275 / S355 Structural Steel | Heavy Structural Profiles

| Item | HEA / HEB / HEM Beams |

|---|---|

| Material Standard | S235 / S275 / S355 |

| Yield Strength | S235: ≥235 MPa; S275: ≥275 MPa; S355: ≥355 MPa |

| Sizes | HEA 100 – HEM 1000; HEA 120×120 – HEM 1000×300, etc. |

| Length | Standard 6 m & 12 m; custom lengths available |

| Dimensional Tolerance | Conforms to EN 10034 / EN 10025 |

| Quality Certification | ISO 9001; Third-party inspection by SGS / BV available |

| Surface Treatment | Hot-rolled, painted, or hot-dip galvanized if required |

| Applications | High-rise buildings, industrial plants, bridges, and heavy-load structures |

Technical Data

EN S235JR/S275JR/S355JR HEA/HEB Chemical Composition

| Steel Grade | Carbon, % max | Manganese, % max | Phosphorus, % max | Sulfur, % max | Silicon, % max | Notes |

|---|---|---|---|---|---|---|

| S235 | 0.20 | 1.60 | 0.035 | 0.035 | 0.55 | General structural steel for building and light industrial applications. |

| S275 | 0.22 | 1.60 | 0.035 | 0.035 | 0.55 | Medium-strength structural steel suitable for construction and bridges. |

| S355 | 0.23 | 1.60 | 0.035 | 0.035 | 0.55 | High-strength structural steel for heavy-load buildings, bridges, and industrial structures. |

EN S235/S275/S355 HEA Mechanical Property

| Steel Grade | Tensile Strength, ksi [MPa] | Yield Point min, ksi [MPa] | Elongation in 8 in. [200 mm], min, % | Elongation in 2 in. [50 mm], min, % |

|---|---|---|---|---|

| S235 | 36–51 [250–350] | 34 [235] | 22 | 23 |

| S275 | 41–58 [285–400] | 40 [275] | 20 | 21 |

| S355 | 51–71 [355–490] | 52 [355] | 18 | 19 |

EN S235/S275/S355 HEA Sizes

| Beam Type | Height H (mm) | Flange Width Bf (mm) | Web Thickness Tw (mm) | Flange Thickness Tf (mm) | Weight (kg/m) |

|---|---|---|---|---|---|

| HEA 100 | 100 | 100 | 5.0 | 8.0 | 12.0 |

| HEA 120 | 120 | 120 | 5.5 | 8.5 | 15.5 |

| HEA 150 | 150 | 150 | 6.0 | 9.0 | 21.0 |

| HEA 160 | 160 | 160 | 6.0 | 10.0 | 23.0 |

| HEA 200 | 200 | 200 | 6.5 | 12.0 | 31.0 |

| HEA 240 | 240 | 240 | 7.0 | 13.5 | 42.0 |

| Dimension | Typical Range | Tolerance (EN 10034 / EN 10025) | Notes |

|---|---|---|---|

| Height H | 100 – 1000 mm | ±3 mm | Can be customized per customer request |

| Flange Width B | 100 – 300 mm | ±3 mm | — |

| Web Thickness t_w | 5 – 40 mm | ±10% or ±1 mm (larger value applies) | — |

| Flange Thickness t_f | 6 – 40 mm | ±10% or ±1 mm (larger value applies) | — |

| Length L | 6 – 12 m | ±12 mm (6 m), ±24 mm (12 m) | Adjustable per contract |

| Customization Category | Options | Description / Range | MOQ |

|---|---|---|---|

| Dimension | H, B, t_w, t_f, L | H: 100–1000 mm; B: 100–300 mm; t_w: 5–40 mm; t_f: 6–40 mm; length tailored to project | 20 tons |

| Processing | Drilling, End Treatment, Prefab Welding | Beveling, grooving, welding, machining to suit connections | 20 tons |

| Surface Treatment | Galvanizing, Paint/Epoxy, Sandblasting, Original | Chosen based on environment and corrosion protection | 20 tons |

| Marking & Packaging | Custom Marking, Shipping Method | Project ID/spec marking; packaging for flatbed or container transport | 20 tons |

Ordinary Surface

Galvanized Surface (hot-dip galvanizing thickness ≥ 85μm, service life up to 15-20 years),

Black Oil Surface

Construction: It is used as beams and columns in multi- story offices, apartments, shopping malls and as primary building and crane beams in factories and warehouses.

Bridge Applications: It is suitable for small to medium-span decks and beams in road, rail, pedestrian bridges.

Public and Specialized Projects: Subway stations, urban pipeline supports, tower crane bases and temporary construction enclosures.

Plant & Equipment Support: The main element of machinery and plant is supported by it, carrying vertical and horizontal loads it resists, which guarantees stability of the machinery and plant.

1) Branch Office - Spanish-speaking support, customs clearance assistance, etc.

2) Over 5,000 tons of stock in stock, with a wide variety of sizes

3) Inspected by authoritative organizations such as CCIC, SGS, BV, and TUV, with standard seaworthy packaging

PACKING

Basic Protection: Each package is wrapped in waterproof tarp and 2-3 desiccant bags are supplied inside.

Strapping: Bundles that weigh 2-3 tons are strapped with 12-16 mm steel straps which are suitable for American port handling.

Labling: The materials are labeled with English/Spanish bilingual labels containing specification, HS code, batch no., and test reports reference.

DELIVERY

Road Transport: Loads are secured with anti-slip devices for road haulage or on-site delivery in one go.

Rail Transport: Perhaps long-distance bulk shipments are more cost effective by rail than by road.

Sea Transport: Long products can be sent on domestic or global journeys in containers, bulk, or open top containers.

Inland Waterway/Barge: If you are looking to transport bulk quantities of non-standard size H-beams, rivers or your local inland waterways might be a good option.

Special Transport: Ultrahuge H-beams or exceedingly heavy I-beams are transported by multi-axle low-bed or combination trailers.

US Market Delivery: EN H-Beams for the Americas are bundled with steel straps and the ends are protected, with an optional anti-rust treatment for the transit.

Q: What Central America standard do your H-beam have?

A: Our H-beam products comply with EN standard which is accepted and widely applied in Central America. We can also do local standard like NOM.

Q: What is the forwarding time to Panama?

A: Ocean cargo from Tianjin Port, China to Colon Free Trade Zone, Panama takes 28-32 days. 45-60 days for total delivery for production and customs clearance. Expedited shipping is available.

Q: Do you help with customs clearance?

A: Yes, we have reputable customs brokers in all of Central America to complete your paperwork, duties and deliveries for a smooth delivery to you.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506