Click to get a FREE 3D Design and Quote within 24 hours!

Heavy-Duty Steel Structure Bridges for Highway Railway and Industrial Projects

APPLICATION

Bridges and Infrastructure Projects: Construction of steel is very common for the building of steel structure bridges, highways, and energy infrastructure, due to its ability to fulfill complex engineering requirements with strength, precision, and versatility.

Industrial factories and plat production:Steel beams like H-beam, I-beam and steel plate can bear heavy load in industrial works. They are suitable for use in equipment platforms, production lines and factory floors.

Warehouses and Logistics Centers:Pre-engineered steel buildings allow for the speedy and cost effective construction of warehouses and distribution centers. Modular components, make it possible to build quickly and provide robustness and longevity.

Commercial and public buildings: Prefabricated steel frames provide a contemporary and adaptable option for commercial building such as in office blocks, shopping centres and sports halls.

PRODUCT DETAIL

Core steel structure products for bridge construction

1. Main steel structure bridge type

| Product Type | Specification Range | Core Function | Central America Adaptation |

|---|---|---|---|

| Truss Bridge | 15–120 m span | Long-span load-bearing structure for vehicles, pedestrians, and light rail | Seismic-grade bolted joints; modular prefabrication; corrosion-resistant for tropical climates |

| Arch Bridge | 20–150 m span | Efficient load transfer for heavy traffic and urban/scenic settings | Hot-dip galvanized steel (Zn ≥ 85 μm); adjustable bearings for seismic activity; modular segments for remote sites |

| Box Girder Bridge | 10–100 m span | High torsional stiffness and bending resistance for highways and elevated roads | Seismic-optimized box section; bolted/welded connections; modular prefabrication for inland transport |

| Pedestrian/Cycling Bridge | 5–50 m span | Lightweight steel structure for safe pedestrian/cyclist use | Anti-slip deck panels; corrosion-resistant; quick-assembly modular design for tropical climates |

2. Enclosure system products (weatherproof + anti-corrosion)

| Product Type | Specification Range | Core Function | Central America Adaptation |

|---|---|---|---|

| Roof Deck Panels | C12×25–C18×35, hot-dip galvanized (Zn ≥ 85 μm) | Supports bridge decking and roof panels; designed for high winds | Corrosion-resistant coating; modular, lightweight for easy transport and quick installation |

| Side Wall Panels | Z10×22–Z16×28, salt spray resistance >1000 hrs | Weatherproof enclosure for walkways and maintenance paths | Ventilated to reduce condensation; corrosion-resistant for hot, humid climates |

| Bracing & Support System | Galvanized round bars Φ14–Φ18 and L60×6 angle steel | Provides lateral stability; withstands hurricane-level winds and seismic forces | Bolted/welded connections for seismic zones; corrosion protection for tropical conditions |

3. Supporting auxiliary products (localized construction adaptation)

| Product Type | Specification Range | Core Function | Central America Adaptation |

|---|---|---|---|

| Expansion Joints | Modular steel or rubber, 50–200 mm width | Allows thermal expansion and contraction of bridge spans | Seismic-grade, corrosion-resistant for tropical and humid climates |

| Guardrails & Safety Barriers | Steel channels or tubes, 900–1200 mm height | Protects vehicles and pedestrians; enhances bridge safety | Anti-corrosion and UV-resistant; suitable for high rainfall and coastal areas |

| Bridge Access Ladders & Platforms | Galvanized ladders Φ32–Φ50, platforms L50×5 | Provides safe inspection and maintenance access | Lightweight, modular, corrosion-resistant for tropical weather |

| Drainage & Water Management Systems | Steel grates Φ12, C-section gutters 100×50–150×75 | Directs rainwater and prevents deck flooding | Hot-dip galvanized or painted for high humidity and storms |

| Lighting & Utility Supports | Steel poles, brackets, cable trays | Supports lighting, signaling, and utility lines | Pre-coated for corrosion resistance; easy mounting and modular replacement |

STEEL STRUCTURE PROCESSING

Cutting

Plasma and flame cut for thick steel plates.

Precision shearing machines for thin plate.

Guaranteed correct size and clean cut edge.

Forming

-

Used for purlins, gutters, and trims.

-

For producing circular members and round supports.

-

Ensures consistent dimensions and shape during fabrication.

Welding

Submerged arc welding is applied for h-beams and big columns

Manual arc welding connection plates and structural joints

CO₂ gas shielded welding for thin plates

Hole Processing

CNC drilling to ensure exact bolt hole alignment

Punch press machines for small-volume production

Accurate positioning enables easy install on site

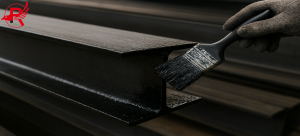

Surface Treatment

Shot blasting/sand blasting to get rid of rust

Grinding of welds, surface polishing/finishing

Galvanizing of bolts and supporting parts for improved corrosion resistance

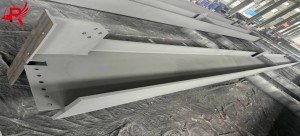

Trial Assembly

Pre-fabricating the columns, beams and bracing systems

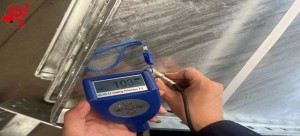

Dimensional inspection with professional measuring instrument

InKine Disassembly after Inspection for secure shipment

STEEL STRUCTURE TESTING

| Test Type | Standard(s) | Purpose / Notes |

|---|---|---|

| Structural Load Test | ASTM A370, EN 10002 | Verify beams, trusses, and girders can safely carry vehicle, pedestrian, and dynamic loads. |

| Weld Quality Inspection | AWS D1.1, ISO 5817 | Ensure welded connections meet standards; critical for truss and box girder joints. |

| Corrosion Resistance | ASTM B117, ISO 9227 | Protect steel in coastal and humid tropical climates. |

| Coating Adhesion Test | ASTM D3359, ISO 2409 | Check paint and galvanizing adhesion; prevents peeling under thermal changes. |

| UV & Weathering Resistance | ASTM G154, ISO 4892 | Prevent surface fading, chalking, and sunlight damage. |

| Humidity & Heat Resistance | ASTM D2247 | Ensure coatings resist blistering and cracking in humid, hot conditions. |

| Impact & Handling Test | ASTM D2794, ISO 6272 | Protect coatings during transport, handling, and assembly. |

| Dimensional & Straightness Check | ISO 8501, EN 1090 | Confirm prefabricated components meet design dimensions for smooth installation. |

| Fatigue & Vibration Test | ASTM E466, ISO 12107 | Verify long-term performance under traffic and wind vibrations. |

| Anchor & Bolted Connection Test | ASTM F606, EN 14399 | Ensure bolts, seismic connectors, and anchors meet load and safety standards. |

SURFACE TREATMENT

PACKAGING AND SHIPPING

Trusses & Girders: Bundled with steel bands and wood supports. Corner protectors and anti-corrosion wrap prevent damage during transport.

Deck & Roof/Wall Panels: Palletized with spacers; wrapped with waterproof and UV-resistant film for tropical climates and long-distance shipping.

Columns & Beams: Crated or bundled with shock-absorbing, rust-free wrapping and labeled for correct handling on site.

Ancillary Parts: Bracing, bolts, and anchors packed in boxes or drums with waterproof protection and labeled for quick assembly.

Transport & Logistics: Shipped by sea, truck, or container; components sized and bundled for safe delivery and fast installation, even to remote sites.

WHY CHOOSE OUR STEEL STRUCTURES?

Custom Designs: Entirely customizeable truss, arch, and box girder bridges for span, load, and site considerations.

Free-Supervision: Service Portable Movers High-Quality Material: Steel production is strictly in accordance with the ASTM, EN, and AASHTO standards.

Accurate Modularization: Modular components are fabricated to precise dimensional specifications before on-site assembly, reducing construction time and errors.

Robust and Weatherproof: Designed for tropical climate, high winds, seismic, heavy traffic.

Fullservice: from designing and manufacturing to packaging, transportation and worksite technical instructions.

Worldwide KnowHow: Central/South America and Southeast Asia based projects, proven include areas specific solutions.

Safe and Efficient Logistics: Modular components which are corrosion protected for ease of transport to remote and land locked locations.

Ready to start your project?

FAQ

Q1: What types of bridges do you provide?

A: Truss, arch, box girder, and pedestrian/cycling bridges, fully custom-engineered.

Q2: What standards do your components meet?

A: ASTM, EN, ISO, and AASHTO; hot-dip galvanizing or weathering steel available.

Q3: Are bridges suitable for tropical and seismic regions?

A: Yes, designed for high wind, seismic activity, and tropical climates.

Q4: How are components packed and shipped?

A: Bundled, crated, and corrosion-protected; labeled for easy on-site assembly.

Q5: Typical lead time?

A: 8–20 weeks depending on design and complexity; modular prefabrication reduces installation time.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506