High Rise Wholesale Steel Structure School Building Factory Structure

Steel Structure are widely used in various building types and engineering projects, including but not limited to the following aspects:

Commercial buildings: such as office buildings, shopping malls, hotels, etc., steel structures can provide large-span, flexible space design to meet the space needs of commercial buildings.

Industrial plants: Such as factories, storage facilities, production workshops, etc. Steel structures have the characteristics of strong load-bearing capacity and fast construction speed, and are suitable for the construction of industrial plants.

Bridge engineering: such as highway bridges, railway bridges, urban rail transit bridges, etc. Steel structure bridges have the advantages of light weight, large span, and fast construction.

Sports venues: such as gymnasiums, stadiums, swimming pools, etc. Steel structures can provide large spaces and column-free designs, and are suitable for the construction of sports venues.

Aerospace facilities: Such as airport terminals, aircraft maintenance warehouses, etc. Steel structures can provide large spaces and good seismic performance designs, and are suitable for the construction of aerospace facilities.

High-rise buildings: such as high-rise residences, office buildings, hotels, etc. Steel structures can provide lightweight structures and good seismic performance designs, and are suitable for the construction of high-rise buildings

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What should you pay attention to when making a steel structure house?

1. Pay attention to the reasonable structure

When arranging the rafters of a steel structure house, it is necessary to combine the design and decoration methods of the attic building. During the production process, it is necessary to avoid secondary damage to the steel and avoid possible safety hazards.

2. Pay attention to steel selection

There are many types of steel on the market today, but not all materials are suitable for building houses. In order to ensure the stability of the structure, it is recommended not to choose hollow steel pipes, and the interior cannot be directly painted, as it is easy to rust.

3. Pay attention to the clear structural layout

When the steel structure is stressed, it will produce obvious vibrations. Therefore, when building a house, we must conduct precise analysis and calculations to avoid vibrations and ensure visual beauty and solidity.

4. Pay attention to painting

After the steel frame is fully welded, the surface should be painted with anti-rust paint to prevent rust due to external factors. Rust will not only affect the decoration of the walls and ceilings, but even endanger safety.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

1.Embedded Parts: Provide stability for the building structure.

2.Pillars: Typically H-shaped steel or paired C-shaped steel connected with angle steel.

3.Beams: Usually H-shaped or C-shaped steel; height depends on beam span.

4.Rods: Generally C-shaped steel, sometimes channel steel.

5.Roof Tiles: Two types—single-layer color steel tiles or insulated composite panels (polystyrene, rock wool, or polyurethane) for thermal and sound insulation.

PRODUCT INSPECTION

Steel structure precast engineering inspection mainly involves raw material inspection and main structure inspection. Among the steel structure raw materials that are often submitted for inspection are bolts, steel raw materials, coatings, etc. The main structure is subjected to weld flaw detection, load-bearing testing, etc.

Examination range

Materials Include:steels, welding consumables, coatings, fasteners, bolts, sealing plates, cone heads, sleeves.

Manufacturing and Installation: Part size, lay-up and single-layer, multi-layer, high-rise and steel mesh lay-up.

Attach and Welding: Welding works, roof bolts welding, normal and highstrengh bolts connections, torque of installation.

Layer Thickness, Adhesion, and Uniformity of Coatings on Steel Structures.

Test Items

Visual and dimensional inspections: Surface finish, geometric accuracy, verticality of structure, accuracy of assembly.

Mechanical and Materials Tests: Tensile, impact, flexural, pressure bearing, strength, stiffness, stability, metallographic and chemical analysis.

Weld Quality: Internal/External Weld Defects, Gel Bleed Out, Non Destructive Testing (Advanced Level).

Fasteners Strength, Torque of Final Tightening, Reliability of Connection.

Coating & Corrosion: Thickness, adhesion, uniformity, ab rasion, salt spray, chemical, moisture, heat, weather, temperature cycling, cathodic protection stripp.

Special Inspections: Ultrasonic and Magetic Particle Flaw Detection, Mobile Communication Tower Mast Examination.

PROJECT

Our company often exports Steel Structure Workshop products to the Americas and Southeast Asian countries. We delivered a project in the Americas spanning 543,000 m² with 20,000 tons of steel for a complex multi-use steel structure for production, living, offices, education and tourism.

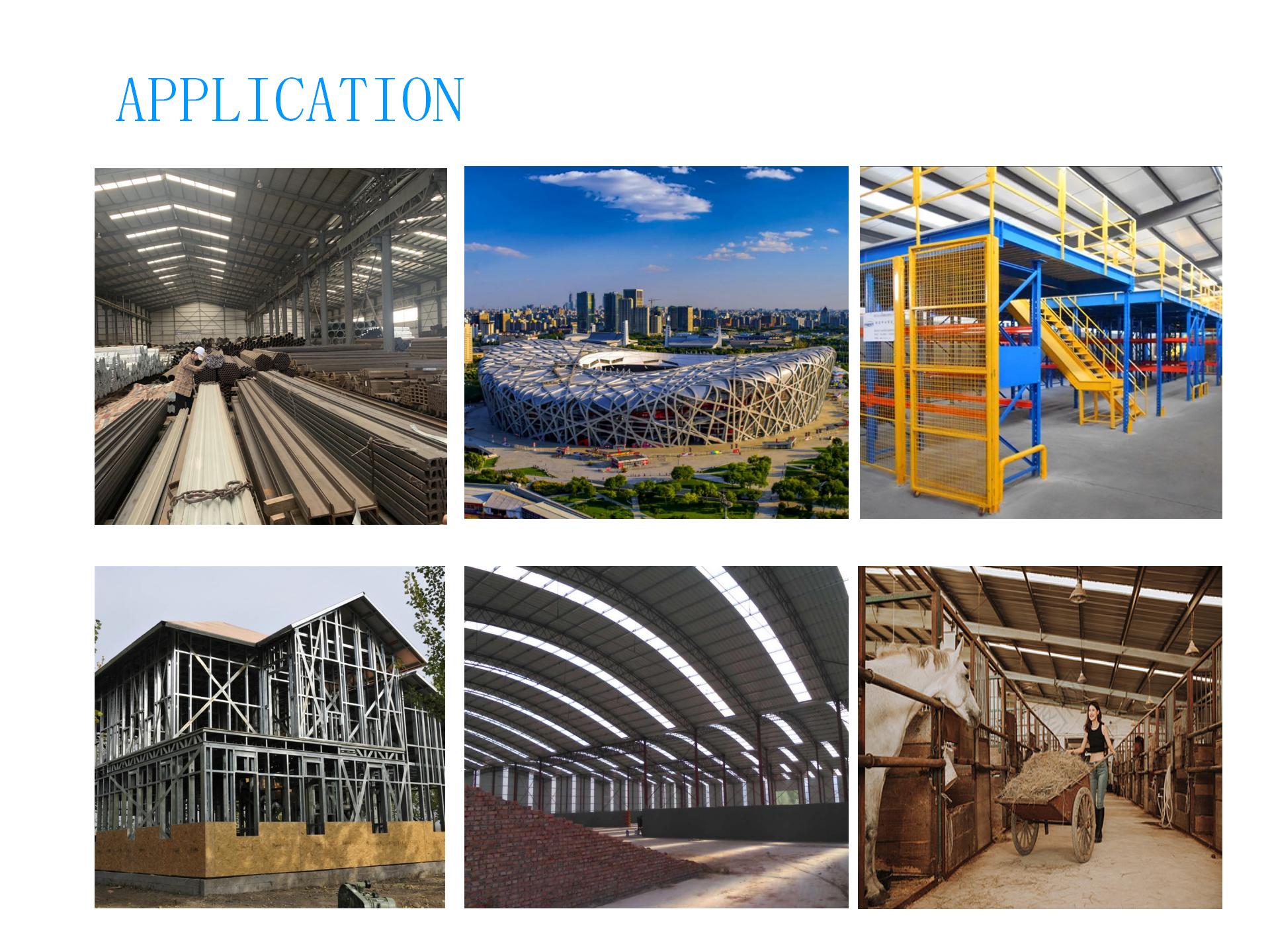

APPLICATION

Economic: Cheaper to produce and maintain; 98% of parts can be reused without loss of strength.

Rapid Installation: Pre-engineered parts and software monitoring the pace of work accelerate construction.

Safe & Healthy: Safe assembly on site is enabled by factory-produced components, with minimal dust and noise.

Versatile: Simple to change and/or add to in the future to meet unforeseen needs, unlike other buildings.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Transport Mode: Select flatbed trucks, containers, or ships based on weight, quantity, distance, and regulations.

Lifting Equipment: Use cranes, forklifts, or loaders with adequate capacity for safe loading and unloading.

Load Security: Properly strap and brace steel components to prevent movement or damage during transit.

COMPANY STRENGTH

Made in China – Excellent Service, Top Quality, Best Choice in Your Life!

1.Scale advantage: big factory and supply chain for efficient production and procurement and one-stop service.

2.Product Range: A large number of steel products including structure, rails, sheet piles, photovoltaic brackets, channel steel, silicon steel coil, etc can meet different requirements.

3.Steady Supply: Constant production and logistics allow steady supply even on large order.

4.Brand Power: Brand visibility, brand credibility and sales staff experience.

5.All Round Service: Customized, production and transportation, all at your disposal.

6.Value for money: Good quality steel at a reasonable price.

*Send the email to [email protected] to get a quotation for your projects

COMPANY STRENGTH

CUSTOMERS VISIT