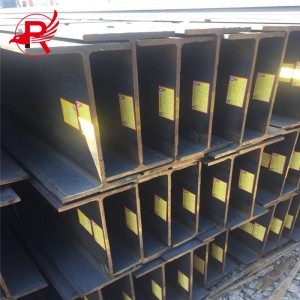

High Quality h16 x 101 150x150x7x10 Q235 Q345b Hot Rolled IPE HEA HEB EN H-Shaped Steel

PRODUCT PRODUCTION PROCESS

These designations signify different types of IPE beams based on their dimensions and properties:

- HEA (IPN) steel sections: These are I-shaped steel beams with wider flanges and thicker webs, suitable for structural applications requiring high load-bearing capacity.

- HEB (IPB) steel sections: These are I-shaped steel beams with moderate flange width and thickness, commonly used in various building structures.

- HEM-type steel sections: These are I-beam steel sections with a larger flange height and a smaller flange width, resulting in higher strength and load-bearing capacity.Different types of steel cross-sections have their own structural design characteristics; therefore, in specific engineering projects, the appropriate type should be selected based on actual requirements.

PRODUCT SIZE

| Designation | Unt Weight kg/m) |

Standard Secional imension mm |

Sectional Ama (cm² |

|||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Designatio | Unit Weight kg/m) |

Standad Sectional Dimersion (mm) |

Sectiona Area (cm²) |

|||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

FEATURES

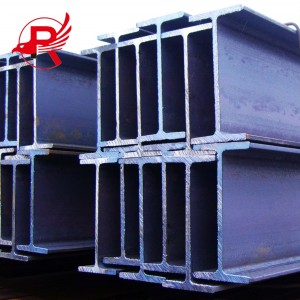

HEA, HEB, and HEM steel sections are types of European standard IPE steel beams (I-shaped cross-section) widely used in construction and structural engineering. Here are the main characteristics of each type:

HEA (IPN) steel section:

Larger flange width and thickness

Suitable for structures with heavy loads

Offers good load-bearing capacity and bending strength

HEB (IPB) steel section:

Moderate flange width and thickness

Versatile, commonly used in various building structures

Combines strength with lightweight advantages

HEM steel section:

Larger flange height and narrower width

Provides higher strength and load-bearing capacity

Suitable for structures with heavy loads and high stress

EN H-Shaped Steel

Grade: EN10034:1997 EN10163-3:2004

Specification:HEA HEB and HEM

Standard: EN

PRODUCT INSPECTION

The key requirements for inspecting H-shaped steel include the following aspects:

Appearance Quality: The appearance of the H-shaped steel should meet relevant standards and customer requirements. The surface should be smooth and even, free from obvious dents, scratches, rust spots, and other defects.

Geometric Dimensions: The length, width, height, web thickness, and flange thickness of the H-shaped steel should comply with relevant standards and customer requirements.

Straightness: The straightness of the H-shaped steel should meet relevant standards and customer requirements. This can be verified by measuring the parallelism of the two ends or using a straightness gauge.

Torsion: The torsion of the H-shaped steel should meet relevant standards and customer requirements. This can be verified by measuring the perpendicularity of the sides or using a torsion tester.

Weight Deviation: The weight of the H-shaped steel should meet relevant standards and customer requirements. Weight deviation can be checked by weighing.

Chemical Composition: If the H-shaped steel requires welding or other processing, its chemical composition should meet relevant standards and customer requirements.

Mechanical Properties: The mechanical properties of the H-shaped steel should meet relevant standards and customer requirements, including tensile strength, yield strength, elongation, etc.

Nondestructive Testing: If nondestructive testing is required for the H-shaped steel, it should be performed according to relevant standards and customer requirements to ensure its internal quality meets specifications.

Packaging and Labeling: The packaging and labeling of the H-shaped steel should comply with relevant standards and customer requirements, facilitating transportation and storage.

In summary, when inspecting H-shaped steel, all of the above requirements should be comprehensively considered to ensure that the quality meets relevant standards and customer requirements, thus providing users with high-quality H-shaped steel products.

APPLICATION

HEA, HEB, and HEM beams have a wide range of applications in the construction and structural engineering industry. Some common uses include:

- Construction Projects: These steel sections are commonly used in the construction of commercial and industrial buildings, providing support for floors, roofs, and other load-bearing structures.

Bridge Engineering: They are used in bridge construction, supporting the bridge deck and other structural components.

Industrial Facilities: HEA, HEB, and HEM steel sections are widely used in the construction of industrial buildings such as warehouses, factories, and storage facilities.

Structural Frames: They can be used to construct the structural frames of large buildings and infrastructure projects, providing support for walls, facades, and other structural elements.

Equipment Support: These steel sections can be used to support heavy machinery and equipment in various industrial environments.

Infrastructure Projects: HEA, HEB, and HEM steel sections are also used in the construction of infrastructure projects such as tunnels, airports, and power plants.

In summary, these steel sections play a crucial role in various construction and engineering projects, providing robust and reliable structural support. Their versatility, strength, and load-bearing capacity make them an indispensable material in modern building and infrastructure design.

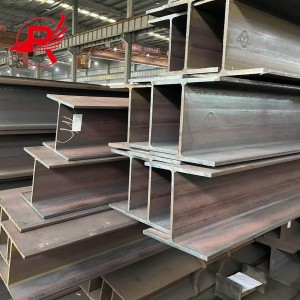

PACKAGING AND SHIPPING

Packaging and Protection

Proper packaging is crucial for ensuring the quality of ASTM A36 H-shaped steel during transportation and storage: Use high-strength steel straps/bands to securely bundle the steel beams to prevent shifting and damage; Use weather-resistant materials such as plastic sheeting or waterproof tarpaulins to protect against moisture and dust, preventing rust.

Loading, Unloading, and Securing

Handle packaged steel beams with care during loading and unloading: Use appropriate lifting equipment such as forklifts or cranes to ensure safety and efficiency; When loading, distribute the steel beams evenly and align them precisely to prevent structural damage; After loading, secure the cargo with ropes, chains, etc., to ensure stability and prevent shifting during transport. This concise summary focuses on key procedures and requirements, making it easier to quickly grasp the essential information. If you wish to further simplify any section or add specific details (such as types of protective materials), please let us know.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.