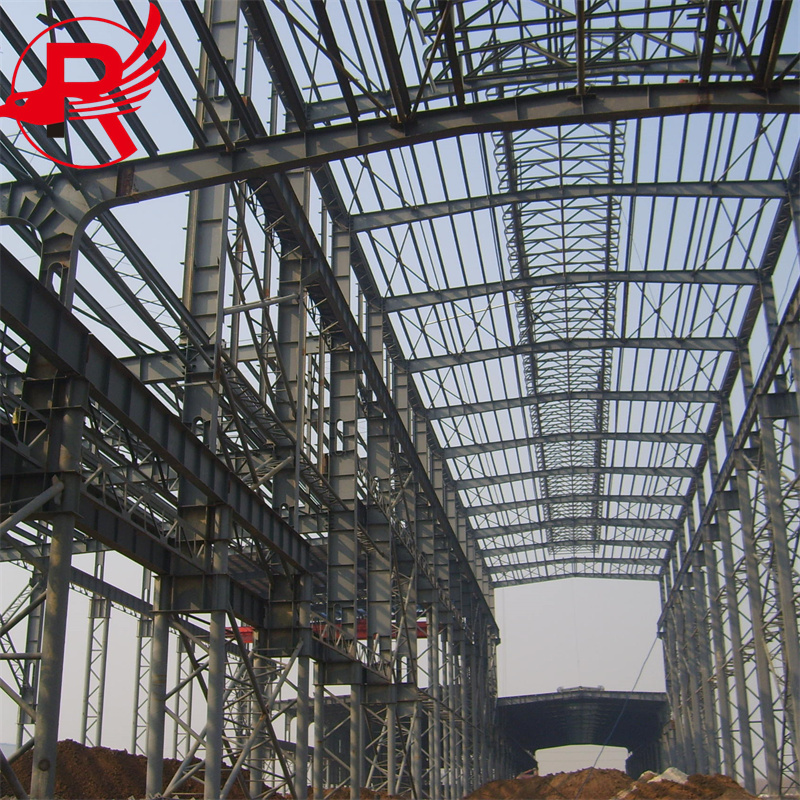

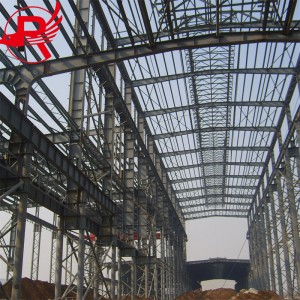

Prefab Warehouse Steel Structure Workshop Industrial Steel Structure Warehouse

prefabricated steel structure is steel structure composed of steel materials and is one of the main building structure types. The structure is mainly composed of steel structure, steel columns, steel trusses and other components made of section steel and steel plates, and adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust prevention processes.

*Depending on your application, we can design the most economical and durable steel frame system to help you create maximum value for your project.

|

Product name:

|

Steel Building Metal Structure

|

|

Material :

|

Q235B ,Q345B

|

|

Main frame :

|

H-shape steel beam

|

|

Purlin :

|

C,Z - shape steel purlin

|

|

Roof and wall :

|

1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

|

Door:

|

1.Rolling gate

2.Sliding door

|

|

Window:

|

PVC steel or aluminum alloy

|

|

Down spout :

|

Round pvc pipe

|

|

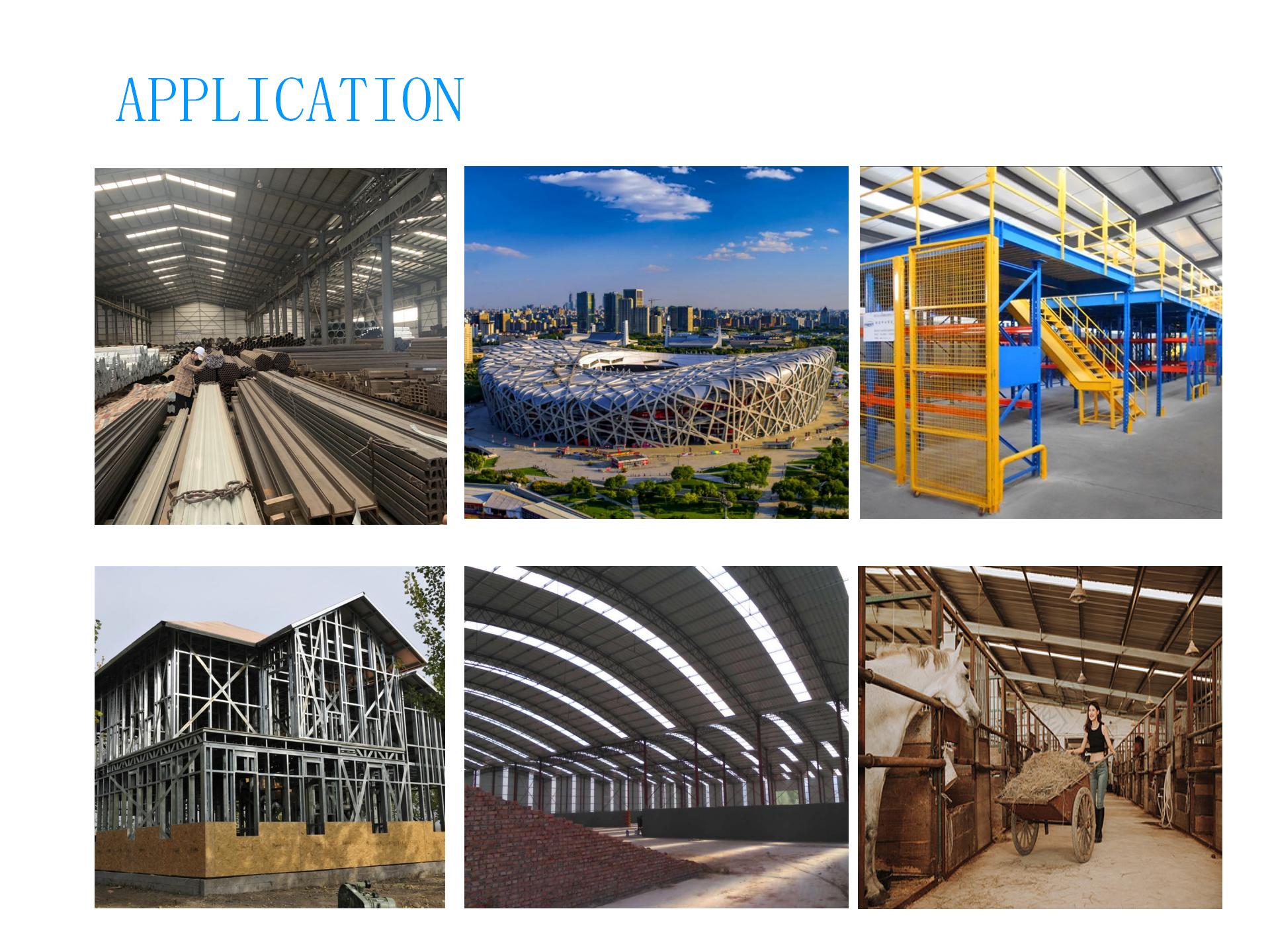

Application :

|

All kinds of industrial workshop ,warehouse ,high-rise building

|

PRODUCT PRODUCTION PROCESS

ADVANTAGE

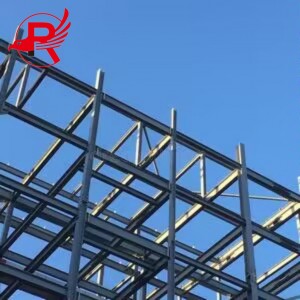

Steel structure is a structure composed of steel materials, which is one of the main types of building structures. The structure is mainly composed of beams, steel columns, steel trusses and other components made of profiled steel and steel plates. It adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust removal and rust prevention processes. Components or parts are usually connected by welding, bolts or rivets. Because of its light weight and easy construction, it is widely used in large-scale factory buildings, stadiums, and super high-rise areas. Steel structures are susceptible to corrosion. Generally, steel structures need to be derusted, galvanized or painted, and regularly maintained.

Steel is characterized by high strength, light weight, good overall rigidity, and strong resistance to deformation. Therefore, it is particularly suitable for the construction of large-span, ultra-high, and super-heavy buildings; the material has good homogeneity and isotropy, which is ideal elasticity Material, which best meets the basic assumptions of general engineering mechanics; the material has good plasticity and toughness, can have large deformation, and can withstand dynamic loads well; the construction period is short; it has a high degree of industrialization, and can be specialized in production with a high degree of mechanization.

For steel structures, high-strength steels should be studied to greatly increase their yield point strength. In addition, new types of steels, such as H-shaped steel (also known as wide-flange steel) and T-shaped steel, as well as profiled steel plates, are rolled to adapt to large-span structures and The need for super high-rise buildings.

In addition, there is a heat-resistant bridge light steel structure system. The building itself is not energy-efficient. This technology uses clever special connectors to solve the problem of cold and hot bridges in the building. The small truss structure allows cables and water pipes to pass through the wall for construction. Decoration is convenient.

The steel component system has the comprehensive advantages of light weight, factory-made manufacturing, fast installation, short construction cycle, good seismic performance, fast investment recovery, and less environmental pollution. Compared with reinforced concrete structures, it has more The unique advantages of the three aspects of development, in the global scope, especially in developed countries and regions, steel components have been reasonably and widely used in the field of construction engineering.

Practice has shown that the greater the force, the greater the deformation of the steel member. However, when the force is too large, the steel members will fracture or severe and significant plastic deformation, which will affect the normal work of the engineering structure. In order to ensure the normal working of engineering materials and structures under load, it is required that each steel member should have sufficient load-bearing capacity, also known as bearing capacity. The bearing capacity is mainly measured by the sufficient strength, stiffness and stability of the steel member.

Sufficient strengthStrength refers to the ability of a steel component to resist damage (fracture or permanent deformation). That is to say, no yield failure or fracture failure occurs under the load, and the ability to work safely and reliably is guaranteed. Strength is a basic requirement that all load-bearing members must meet, so it is also the focus of learning.

Sufficient stiffnessStiffness refers to the ability of a steel member to resist deformation. If the steel member undergoes excessive deformation after being stressed, it will not work properly even if it has not been damaged. Therefore, the steel member must have sufficient stiffness, that is, no stiffness failure is allowed. Stiffness requirements are different for different types of components, and relevant standards and specifications should be consulted when applying.

StabilityStability refers to the ability of a steel component to maintain its original equilibrium form (state) under the action of an external force.

The loss of stability is the phenomenon that the steel member suddenly changes the original equilibrium form when the pressure increases to a certain degree, which is referred to as instability. Some compressed thin-walled members may also suddenly change their original equilibrium form and become unstable. Therefore, these steel components should be required to have the ability to maintain their original equilibrium form, that is, have sufficient stability to ensure that they will not be unstable and damaged under the specified conditions of use.

The instability of the pressure bar generally occurs suddenly and is very destructive, so the pressure bar must have sufficient stability.

PRODUCT DETAILS

The construction of Steel Structure Design factory buildings is mainly divided into the following five parts:

1. Embedded parts (can stabilize the factory structure)

2. Columns are usually made of H-shaped steel or C-shaped steel (usually two C-shaped steels are connected with angle irons)

3. Beams generally use C-shaped steel and H-shaped steel (the height of the center area is determined according to the span of the beam)

4. Steel purlins: C-shaped steel and Z-shaped steel are generally used.

5. Support points and push bars are usually round steel.

6. Tiles are divided into two types. The first is chip tiles (color steel roofing). The second type is sandwich panel. (The double-layer color-coated board sandwiched between polyurethane or rock wool boards has the effect of keeping warm in winter and cool in summer, and also has sound insulation and fire prevention effects).

Application

Industrial buildings:Steel structure building case are often used in factories or warehouses. The prefabricated module, and the processing, manufacturing, transportation and installation are very fast. Moreover, it is light in weight and has strong carrying capacity and shock resistance, which can ensure the safety and stability of the plant. In addition, the steel structure can be disassembled and rebuilt according to needs, with strong flexibility.

Agricultural buildings: For various crops and horticultural crops, it has the advantages of high light transmittance, high thermal efficiency, energy saving and low operating costs. The product adopts all-steel frame support structure and space overall column-free design form, so that the bearing capacity of the greenhouse is stronger, more stable and reliable, and the same applies to farmed animals.

Public buildings:Now many high-rise buildings or gymnasiums use steel structure, it can effectively protect the building from natural disasters and man-made damage, such as earthquake, fire and so on; Steel structure is not easy to corrosion, high temperature resistance, fire resistance, easy maintenance; Steel structures are usually made of high-strength materials, and the steel itself does not require processing equipment, so it saves a lot of investment

Residence: The characteristics of the Steel structure have the conditions to make the building light and transparent, which can realize the large-span space modeling and local more complex modeling creativity. It's cheap and energy efficient.

Device platform: The raw material of the steel structure platform has good plastic deformation and ductility, and can have great deformation, so it can bear the driving force load very well. It is also can shorten construction period and save time and manpower. The mechanical automation level of steel structure engineering is high, which can carry out systematic production and manufacturing, improve work efficiency, reduce the difficulty factor of engineering construction, and meet the characteristics of the current high-speed operation and environmental protection social development.

PRODUCT INSPECTION

Before shipping steel structure products, parts must be inspected to ensure that the quality of the product is intact. Steel components should be inspected for size, shape, surface quality, etc. Damaged or partially non-compliant parts should be replaced or repaired in a timely manner. The quality inspection of steel structure projects includes all specified test and inspection contents of raw materials, welding materials, weldments, fasteners, welds, bolt ball joints, coatings and other materials and projects of steel structures. Sampling testing, steel chemical composition analysis, paint and fire retardant coating testing.

PROJECT

Our company has cooperated with many steel structure company building projects in America, Southeast Asia and other countries.

The area of steel structure factory buildings is about 50,000 square meters.

Steel structure factory buildings are mainly composed of foundations, steel columns, steel beams, roofs and walls.

Foundation: The foundation embedded parts are an important part of the factory building structure. They are mainly responsible for transmitting the weight of the factory building to the ground and ensuring the stability of the factory building.

Steel column: Steel column is the main load-bearing component of the factory building. It needs to bear the weight of the entire factory building, so the steel column needs to have sufficient strength and stability.

Steel beam: Steel beam is also one of the main load-bearing components of the factory building. It and the steel column jointly bear the weight of the factory building.

Roof: The roof is an important part of the factory building. It needs to have functions such as waterproofing, heat preservation, and heat insulation. The roof is generally composed of color steel plates, purlins, supports and other components.

Wall: The wall is another important part of the factory building. It needs to have functions such as thermal insulation, sound insulation, and waterproofing. Walls are generally composed of wall panels, insulation materials, supports and other components.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the steel structure, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the steel structure, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Steel Structure on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structure, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT