A Steel Sheet Pile is a prefabricated, interlocking steel section used to create retaining walls, cofferdams, and waterfront structures, providing strong soil retention and water-tight barriers in construction and civil engineering projects.

Steel Sheet Piles

-

-

Steel Sheet Pile Factory Az12/Au20/Au750/Az580/Za680 Hot Rolled Sale Types of Steel Sheet Pile

Larsen steel sheet pile support structures are commonly used in foundation pit enclosure construction methods, commonly known as fenders. Due to the different specifications of Larsen steel sheet piles and their wide use areas, Larsen steel sheet piles need to be transported to the construction site before actual use. , generally choose to transport Larsen steel sheet piles by car. If the distance is long and the demand is large, it will be more economical and faster to ship Larsen steel sheet piles. Jiaohang Shipping Center has just undertaken the port-to-door transportation of tens of thousands of tons of Larsen steel sheet piles. This Among them is the issue of how to safely load and unload Larsen steel sheet piles.

-

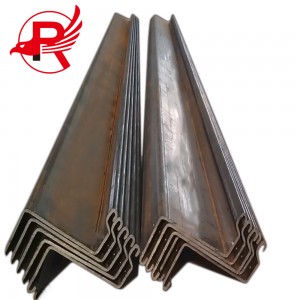

Hot Rolled Steel Sheet Pile Z Type Steel Sheet Pile

High carrying capacity. Steel has high strength and can be effectively driven into hard soil layers. The pile body is not easily damaged and a larger single pile bearing capacity can be obtained. The project quality is reliable and the construction speed is fast. It is light in weight, has good rigidity, is easy to load, unload, transport and stack, and is not easily damaged.

-

China Supplier Sufficient Stock Hot Rolled U Type Steel Sheet Piles

Steel sheet piles use steel as the basic material, which is highly renewable and does not produce a large amount of waste concrete and other environmental pollutants.

-

Factory Supply Sheet Pile Steel Price of Type 2 Steel Sheet Pile Type 3 Hot Z-Shaped Steel Sheet Pile Best Price

1. The pile length is easy to adjust. The length of steel sheet piles can be lengthened or cut as needed.

2. Connector connection is very simple. It can be welded by electric welding, which is simple to operate, high in strength and safe to use.

3. The amount of abandoned soil is small and has little impact on adjacent buildings (structures). Due to the opening at the lower end of the pile, soil will be squeezed into the pile tube when the pile is driven. Compared with actual piles, the amount of soil squeezed is greatly reduced, causing little disturbance to the surrounding foundation, avoiding soil uplift, and greatly reducing the effects of vertical displacement and horizontal displacement of the pile top.

-

Cold Formed and Hot Rolled Larsen Q235 Q345 Q345b Sy295 Sy390 Metal Sheet Piling Z Type Steel Sheet Pile 6m 12m

Steel sheet piles can be used as one of the construction technologies for foundation engineering construction, and are suitable for basic parts of various construction projects, such as basements, frame structures, house exteriors, etc.

-

ASTM 6m 9m 12m Hot Rolled Z Type Steel Sheet Pile

Z-shaped steel sheet piles, a highly effective and widely used retaining material, are named for their resemblance to the letter “Z” in their cross-section.U-type (Larsen) steel sheet piles The two types together make the backbone of modern steel sheet pile engineering with significantly different features in structural performance and field of application.

Advantages:

-

High section modulus-to-weight ratio for efficiency

-

Increased stiffness minimizes deflection

-

Wide design allows easy installation

-

Superior corrosion resistance, with extra thickness at critical points

-

-

q235 q355 Hot u Steel Sheet Piling Model Construction Construction Price

With the development of China’s economy, the superior performance of hot rolled steel sheet pile is favored by more and more people, and the hot rolled steel sheet pile will be widely developed in the future. And the production technology of hot rolled steel sheet pile.

-

U Type Hot Rolled Steel Sheet Piles Is Mainly Used In Construction

U Type Hot Rolled Steel Sheet Piles, as a new building material, can be used as soil retaining, water retaining and sand retaining wall in the construction of bridge cofferdam, large-scale pipeline laying and temporary ditch excavation. It plays an important role in engineering such as retaining wall, retaining wall and embankment protection in wharf and unloading yard. Larsen steel sheet pile as cofferdam is not only green, environmental protection, but also fast construction speed, low construction cost, and has a good waterproof function.

-

Best Price s275 s355 s390 400x100x10.5mm u Type 2 Carbon Ms Hot Rolled Steel Sheet Piling For Construction

As a commonly used infrastructure material, the main role of steel sheet piles is to form a support system in the soil to support the weight of buildings or other structures. At the same time, steel sheet piles can also be used as basic materials in engineering structures such as cofferdams and slope protection. Steel sheet piles are widely used in construction, transportation, water conservancy, environmental protection and other fields

-

ASTM Az Pz Nz 6m 9m 12m Hot Rolled Z Type Steel Sheet Pile

Z-shaped steel sheet piles, a highly effective and widely used retaining material, are named for their resemblance to the letter “Z” in their cross-section.U-type (Larsen) steel sheet piles The two types together make the backbone of modern steel sheet pile engineering with significantly different features in structural performance and field of application.

Advantages:

-

High section modulus-to-weight ratio for efficiency

-

Increased stiffness minimizes deflection

-

Wide design allows easy installation

-

Superior corrosion resistance, with extra thickness at critical points

-

-

Hot Rolled Au Pu 6m-18m U-shaped Steel Sheet Pile

Hot Rolled Au Pu 6m-18m U-Shaped Steel Sheet Pile is a durable, high-strength steel piling solution designed for retaining walls, waterfront structures, and earth retention projects.