Steel Structure Commercial and Industrial Warehouse Steel Structure

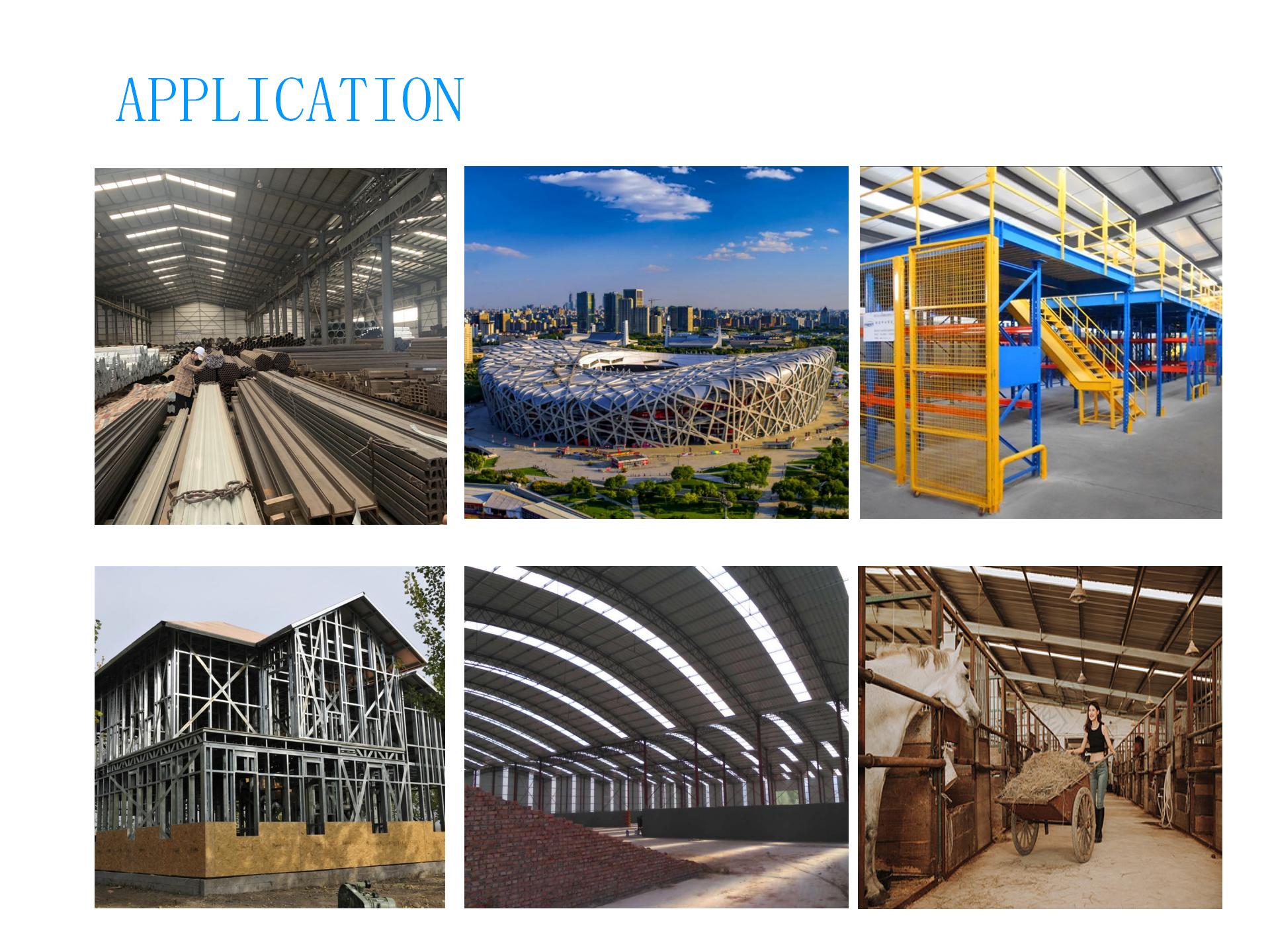

Steel Structure are widely used in various building types and engineering projects, including but not limited to the following aspects:

Commercial buildings: such as office buildings, shopping malls, hotels, etc., steel structures can provide large-span, flexible space design to meet the space needs of commercial buildings.

Industrial plants: Such as factories, storage facilities, production workshops, etc. Steel structures have the characteristics of strong load-bearing capacity and fast construction speed, and are suitable for the construction of industrial plants.

Bridge engineering: such as highway bridges, railway bridges, urban rail transit bridges, etc. Steel structure bridges have the advantages of light weight, large span, and fast construction.

Sports venues: such as gymnasiums, stadiums, swimming pools, etc. Steel structures can provide large spaces and column-free designs, and are suitable for the construction of sports venues.

Aerospace facilities: Such as airport terminals, aircraft maintenance warehouses, etc. Steel structures can provide large spaces and good seismic performance designs, and are suitable for the construction of aerospace facilities.

High-rise buildings: such as high-rise residences, office buildings, hotels, etc. Steel structures can provide lightweight structures and good seismic performance designs, and are suitable for the construction of high-rise buildings

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What should you pay attention to when making a steel structure house?

1. Pay attention to the reasonable structure

When arranging the rafters of a steel structure house, it is necessary to combine the design and decoration methods of the attic building. During the production process, it is necessary to avoid secondary damage to the steel and avoid possible safety hazards.

2. Pay attention to steel selection

There are many types of steel on the market today, but not all materials are suitable for building houses. In order to ensure the stability of the structure, it is recommended not to choose hollow steel pipes, and the interior cannot be directly painted, as it is easy to rust.

3. Pay attention to the clear structural layout

When the steel structure is stressed, it will produce obvious vibrations. Therefore, when building a house, we must conduct precise analysis and calculations to avoid vibrations and ensure visual beauty and solidity.

4. Pay attention to painting

After the steel frame is fully welded, the surface should be painted with anti-rust paint to prevent rust due to external factors. Rust will not only affect the decoration of the walls and ceilings, but even endanger safety.

DEPOSIT

The construction of Steel Structure Factory buildings is mainly divided into the following five parts:

1.Embedded Parts: Reinforce and make stable the factory building.

2.Columns: H or double C-shape steel connected by angle steel.

3.Beams: H or C steel shape with the height determined by the span.

4.Bracing: Generally c-channel or channel steel, more support.

5.Roof and Wall Panels: single colour steel sheets or insulated composite panels (polystyrene,rock wool or polyurethane) for thermal/sound insulation.

PRODUCT INSPECTION

The inspection of steel structure precast engineering is mainly the raw material inspection and the main structure inspection. Frequently tested materials include bolts, steel, and coatings, and the main structure is subjected to weld flaw detection and load testing.

Inspection Scope:

It covers the steel and fully welded single span and multi-span bridges modular unit, also the welding materials, fasteners, coatings, components dimensions, quality of assembly, bolt torque, coating thickness etc on the single to multi-layer steel structure.

Test Items:

Spear Parts of appearance, NDT (UT/MPT), tensile, impact and bending test, chemical composition, weld quality, coating adhesion, corrosion protection, dimensional accuracy, tensile, modulus of elasticity, strength, stiffness and overall stability.

PROJECT

Our company is a steel structure China factory.Our company has been finished and exported steel structure workshop to South America and Southeast Asia etc. One project in the Americas covers an area of 543,000 square meters with 20,000 tons of steel, the multi-purpose complex for production, living, offices, education, and tourism.

Advantages

1. Cost Reduction

Steel structures have lower production and maintenance costs than traditional building structures. Furthermore, 98% of steel components can be reused in new structures without compromising mechanical properties.

2. Fast Installation

The precision machining of steel components speeds installation and can be monitored through management software, accelerating construction progress.

3. Health and Safety

The warehouse's steel components were manufactured in a factory and safely installed on-site by a professional installation team. Field investigations have proven that steel structures are the safest solution.

Because all components are prefabricated in the factory, dust and noise generated during construction are minimal.

4. Flexibility

Steel structures can be modified based on future needs. Their load-bearing capacity, extended reach, and other properties fully meet the client's requirements, which are unattainable with other structures. The Wholesale Steel Structure School Building is a prime example.

PACKAGING AND SHIPPING

Packing: According to your requirements or the most suitable.

Shipping:

Select a proper transport modes: base on the volume and weight of the steel structure, choose a proper modes of transport such as flatbed truck, container, ship or others. Take into account distance, time, cost, route and local regulations of transportation.

Employ proper lifting tools: Utilize appropriate lifting gear (cranes, forklift, loaders etc.) to load and discharge the steel structure. Make sure that the equipment employed is capable of safely bearing the weight of sheet piles.

Tie down the load: Strap, brace or otherwise adequately secure the packaged bundle of steel structure load on the transportation vehicle to prevent shifting, sliding, or falling off while in transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1.Efficiency of production, procurement and service due to large factory and large supply chain.

2.Product Categories: Various types of steel products (structures, rails, sheet piles, solar brackets and channels) and silicon steel coils to satisfy customers’ different demands.

3.Dependable Supply: Steady production lines guarantee stable supply, very suitable for mass orders.

4.Dominant Brand: Establish a strong and respected market presence.

5.One-Stop Service: Customize production and transportation integrated solution.

6.Reasonable price for the good quality steel.

*Send the email to [email protected] to get a quotation for your projects

COMPANY STRENGTH

CUSTOMERS VISIT