U Type Profile Hot Rolled Steel Sheet Pile

|

Products

|

|

|

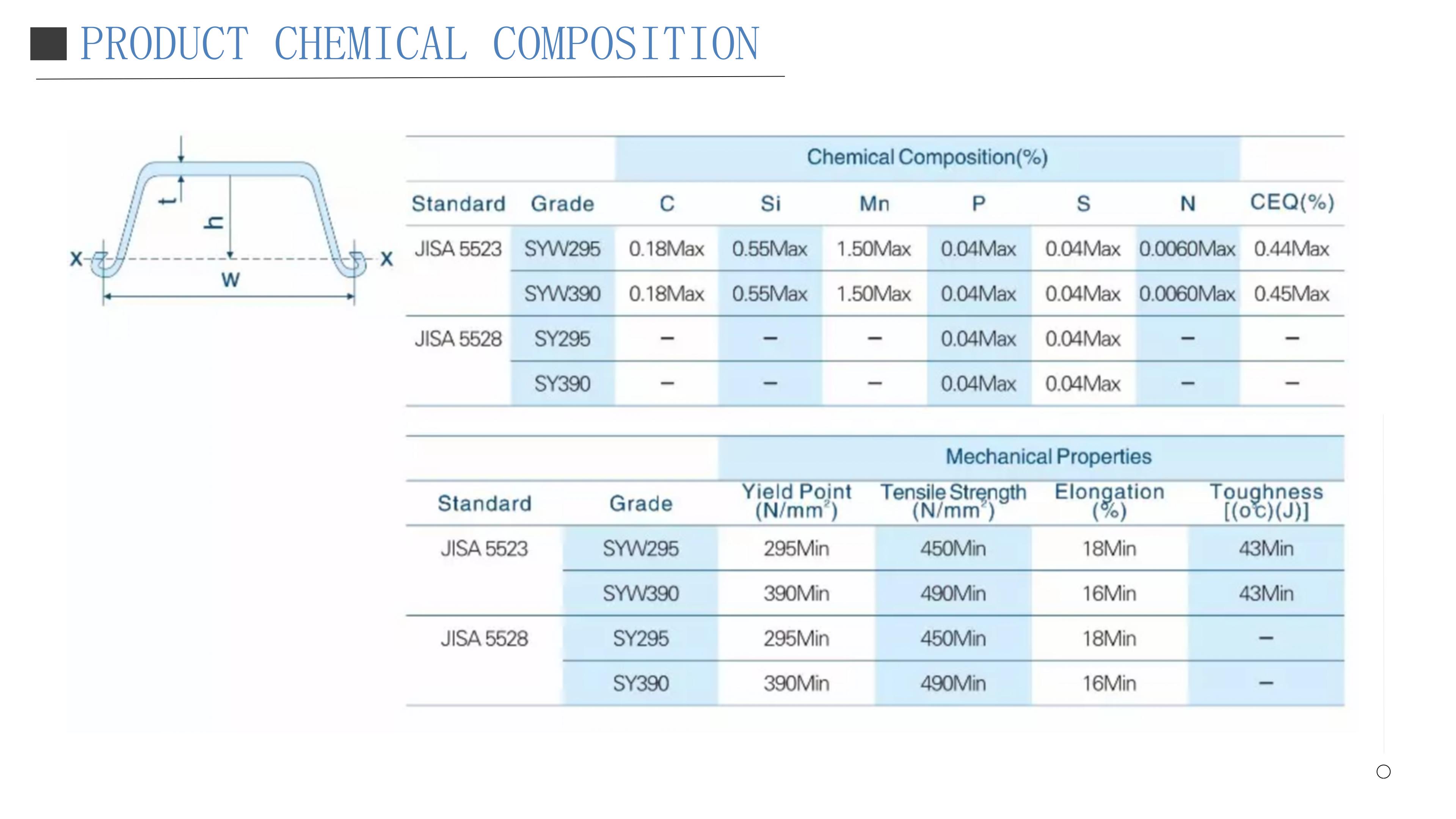

Standard

|

SY295, SY390, SYW295, SYW390, Q345, Q295PC, Q345P, Q390P, Q420P, Q460P

|

|

Grade

|

GB standard,JIS standard,EN standard

|

|

Type

|

U/Z/W sheet pile

|

|

Technical

|

hot rolled

|

|

Length

|

6/9/12 or as customer requested

|

|

Application

|

Products for building harbor, shipyard, port, bridge, cofferdam and so on

|

|

Supply ability

|

10000tons per month

|

|

Delivery Details :

|

7-15 days after receiving your deposit . Depends on your oder quantity.

|

*Send the email to [email protected] to get a quotation for your projects

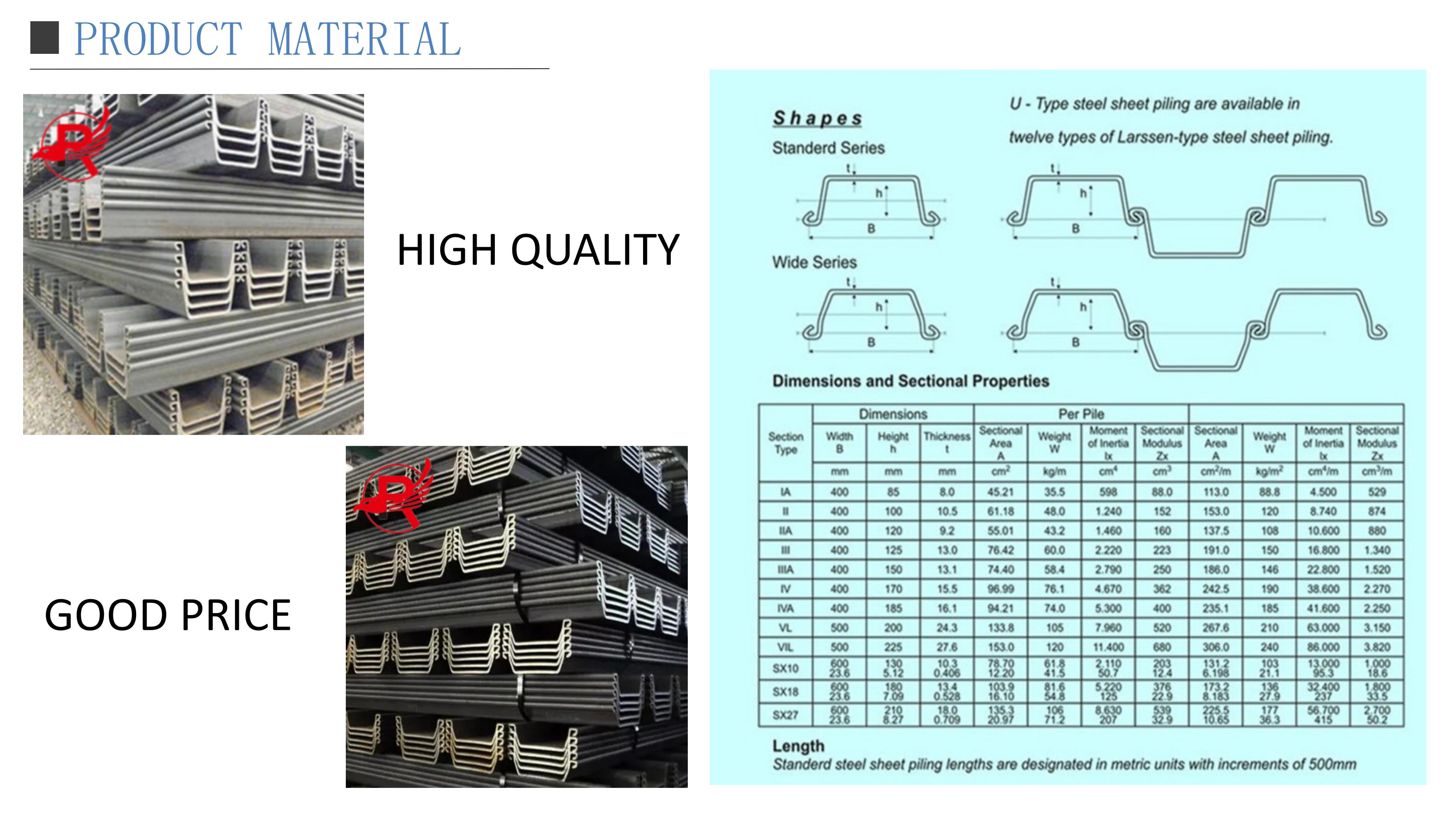

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

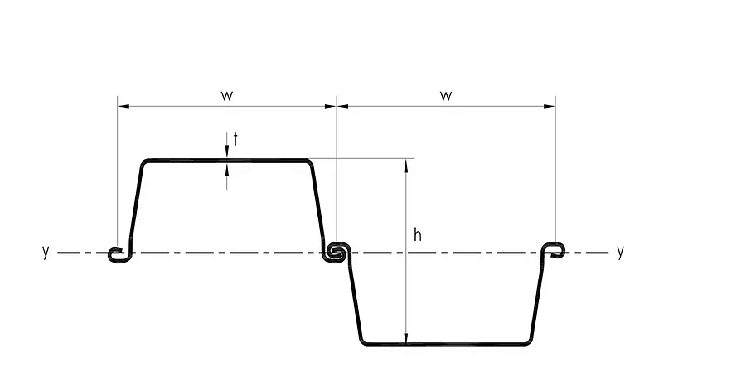

PRODUCT SIZE

FEATURES

1. High strength: U-shaped steel sheet piles are made from high-quality steel, which provides excellent strength and stiffness. This allows them to withstand heavy loads, soil pressures, and water pressures.

2. Versatility:500 x 200 u sheet pile can be used in a wide range of applications, including retaining walls, cofferdams, and foundation support. They are also suitable for use in both permanent and temporary structures.

3. Efficient installation: These foundation piles are designed with interlocking systems that enable quick and efficient installation. The interlocking system allows the piles to be connected together tightly, ensuring stability and preventing soil or water leakage.

4. Excellent Durability: U-shaped steel sheet piles are extremely corrosion-resistant and can withstand extreme weather conditions, making them suitable for long-term use in a variety of environments. Furthermore, U-shaped steel sheet piles can be coated or treated with special treatments to enhance their durability and corrosion resistance.

5. Easy Maintenance: U-shaped steel sheet piles generally require minimal maintenance. Any necessary repairs or maintenance can usually be performed without extensive excavation or disruption to surrounding structures.

6. Cost-Effectiveness: Foundation piles offer a cost-effective solution for many construction projects. They offer a long service life, low maintenance costs, and efficient installation, resulting in cost savings.

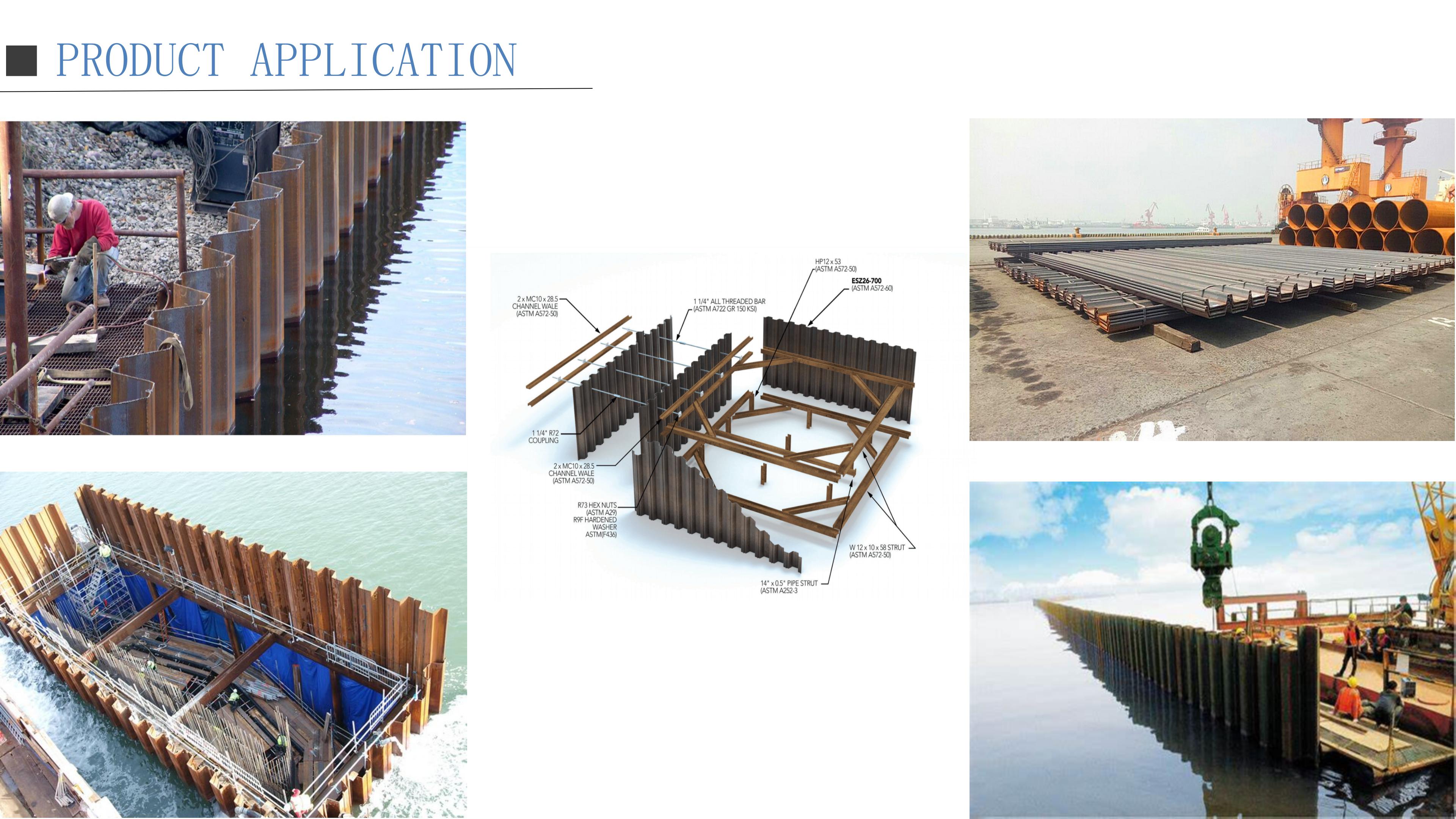

APPLICATION

U-shaped steel sheet piles have a wide range of applications in various industries and construction projects. Some of the common applications include:

Retaining walls:foundation piles are extensively used for constructing retaining walls to support soil or water pressure. They provide stability and prevent soil erosion, making them suitable for infrastructure projects such as bridge abutments, underground parking structures, and waterfront developments.

Cofferdams and Cutoff Walls: Foundation piles are used to construct temporary or permanent cofferdams in bodies of water. They form a barrier, lowering the water level in an area and protecting construction activities from water infiltration. They can also serve as cutoff walls, blocking water flow and controlling groundwater levels at construction sites.

Deep Foundation Systems: Foundation piles are part of deep foundation systems (such as composite walls and slurry walls) used to support foundation pits and stabilize the soil. Depending on the project's needs, they can be used as temporary or permanent solutions.

Flood Control: Foundation piles are used to prevent flooding in low-lying areas. They can be set along riverbanks, coasts, or coastal areas to provide reinforcement and resistance to water flow, protecting surrounding infrastructure and property.

Marine Structures: U-shaped steel sheet piles are widely used in the construction of various marine structures, including seawalls, breakwaters, piers, and ferry terminals. They provide stability and prevent erosion caused by waves and currents in coastal areas.

Underground Structures: Foundation piles are used to stabilize the foundation pits of underground structures such as basements, underground parking lots, and tunnels. They provide temporary or permanent support to prevent soil collapse and ensure safety during construction.

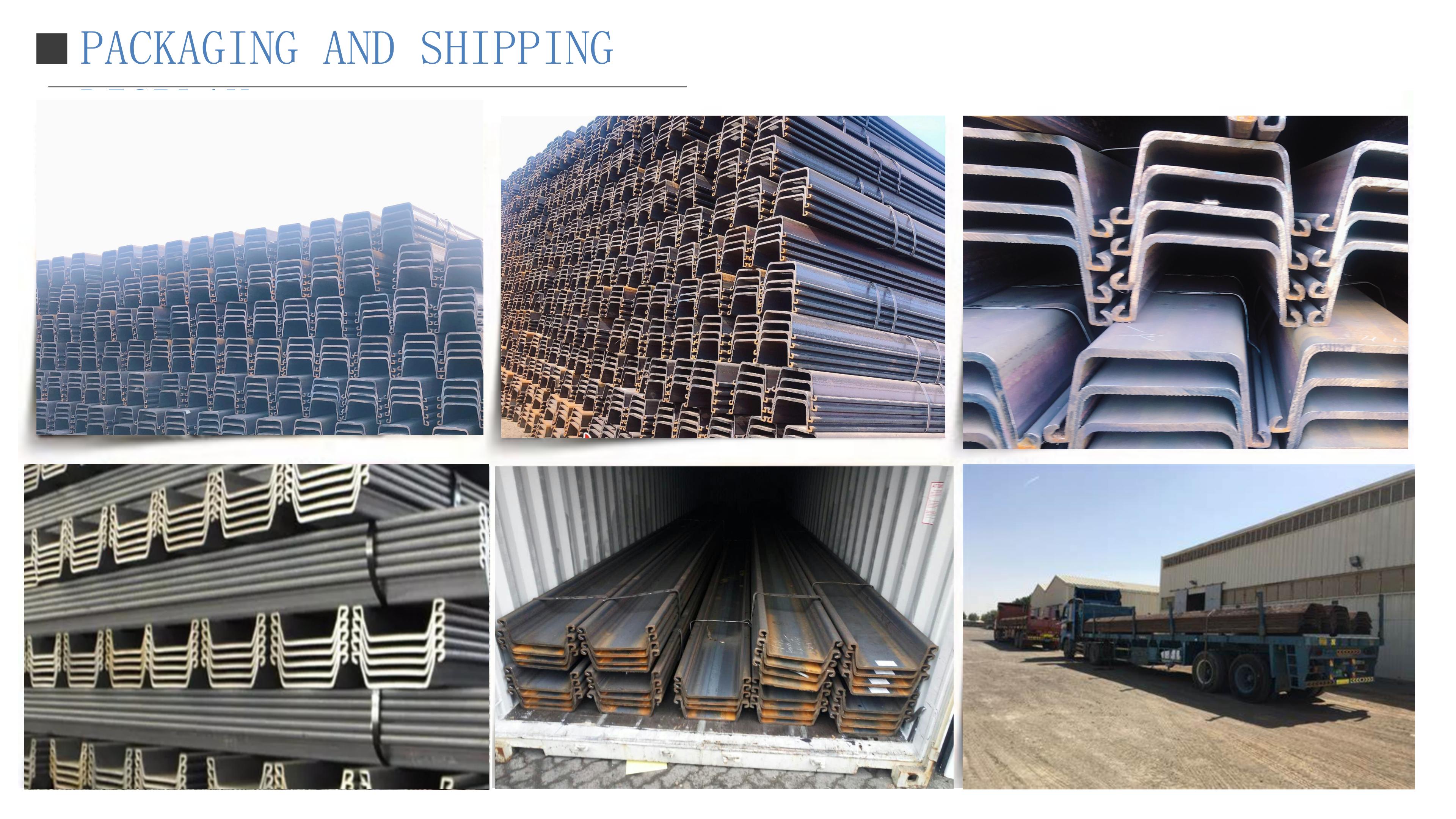

AGING AND SHIPPING

Packaging:

Stack the sheet pile u type securely: Arrange the U-shaped sheet piles in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging materials: Wrap the stack ofsheet pile u type with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the sheet piles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the U-shaped steel sheet piles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack ofsheet pile u type on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

When a customer wishes to visit a product, the following steps are typically arranged:

Scheduling a visit: Customers can contact the manufacturer or sales representative in advance to schedule a time and location for a product visit.

Arranging a guided tour: A professional or sales representative will serve as a guide to explain the product's production process, process technology, and quality control procedures.

Product Display: During the tour, products at various stages of production are displayed to the customer, allowing them to understand the production process and quality standards.

Answering questions: During the tour, customers may have various questions, and the tour guide or sales representative should patiently answer them and provide relevant technical and quality information.

Providing samples: If possible, product samples can be provided to help them better understand the product's quality and features.

Follow-up: After the tour, follow up promptly with the customer's feedback and needs to provide further support and service.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.